Processing method for easy-care clothing fabric

A processing method and fabric technology, which is applied in the field of garment fabric processing, can solve the problems affecting appearance and wearing performance, Tencel fiber is easy to wrinkle, and frosting occurs, so as to improve wearing value and grade, improve wrinkle recovery ability, and gloss soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

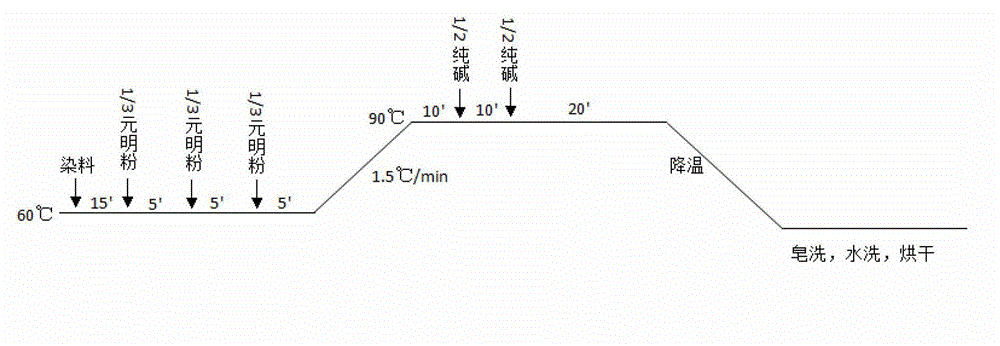

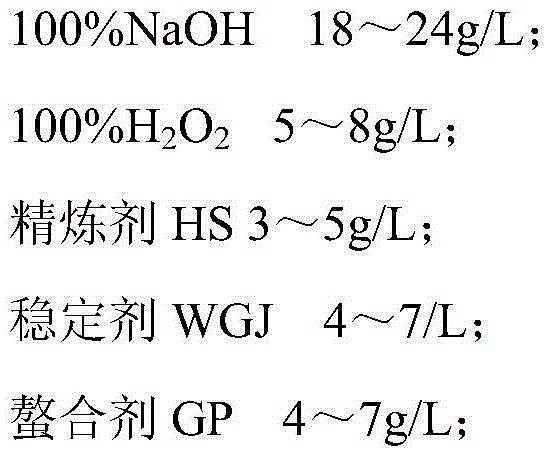

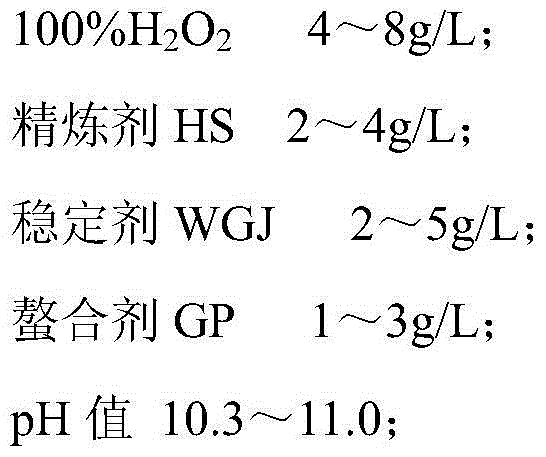

Method used

Image

Examples

Embodiment 1

[0072] Example 1: Choose Klein’s NDF crosslinking agent for finishing, the formula is as follows: crosslinking agent NDF: 70g / l; catalyst NKS: 16g / l; leavening agent NMW: 5g / l; softener UP: 10g / l .

Embodiment 2

[0073] Example 2: BASF's Silk Fuping FR-ECO resin was selected for finishing. The formula is as follows: Silk Fuping FR-ECO: 70g / L, catalyst MgCl2·6H2O: 10g / L.

[0074] 5) Tenter:

[0075] Cellulose fibers are plastic in a wet state, and the moisture regain of the fabric is kept at 10% to 15% by moistening and pre-drying, and then the fabric is stretched to a specified width, and then dried. In the tentering process, softener TIP, softener IPS, etc. can be added to adjust the hand feeling of the fabric, improve the hygroscopicity of the fabric, and improve the wearing comfort of the fabric after it is finished.

[0076] 6) Pre-shrinking: The conventional pre-shrinking finishing of the fabric is carried out by mechanical and physical methods, and finally the cellulose fiber clothing fabric with stable dimensional properties is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com