Vacuum guide roller

A guide roller and vacuum technology, which is applied in the field of papermaking machinery, can solve the problems of power consumption, high maintenance difficulty, and high value, and achieve the effects of reducing relative motion, reducing power consumption and felt loss, and eliminating sliding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

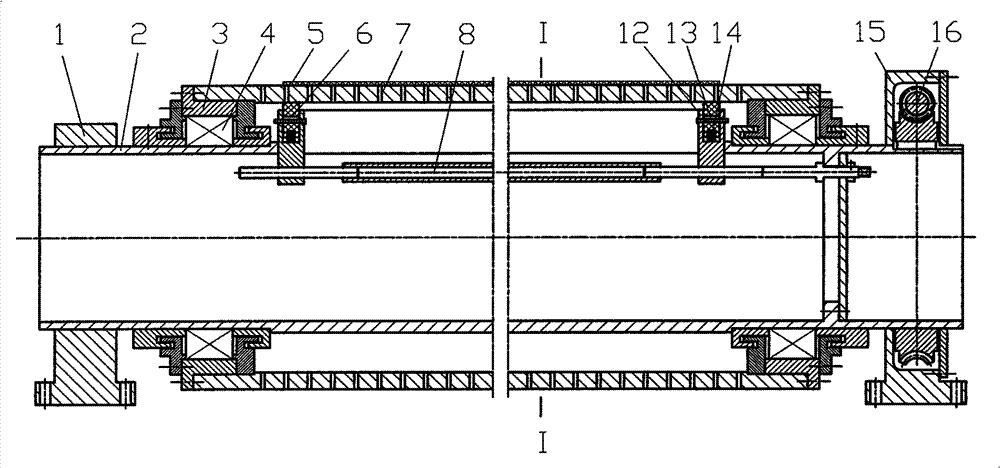

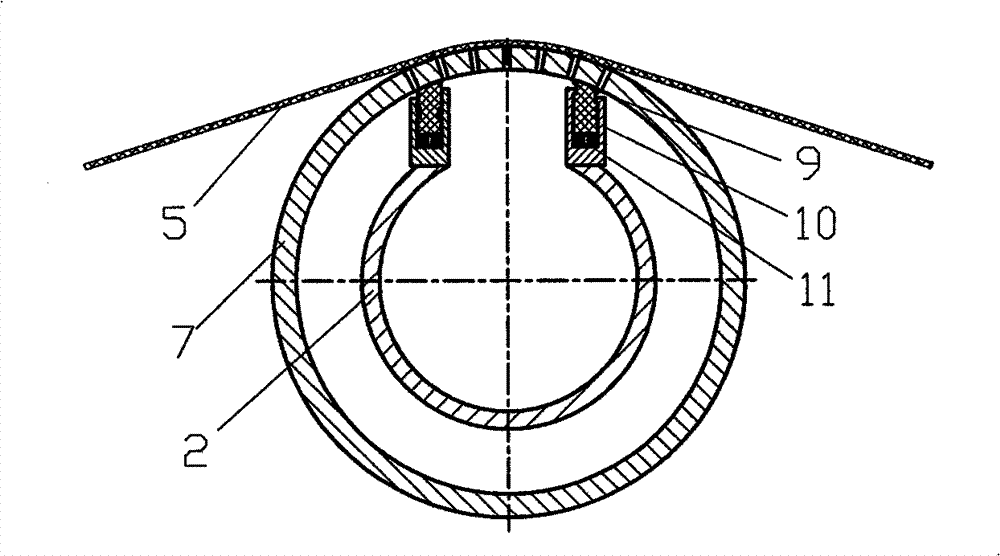

[0012] like figure 1 and figure 2 The specific embodiment of the present invention shown is mainly composed of housing 7, hollow mandrel 2, sealing device, bearing device and other components. Inside and outside, bearing devices are installed at both ends of the shell. The bearing device is mainly composed of bearing chamber 3, bearing 4 and labyrinth seal. Bearing chamber 3 is fixed at both ends of the shell 7. The two ends of the shaft are fixed on the roller support 1 and the support 15, and the worm wheel 16 and the worm are housed in the support 15. The mandrel 2 is a hollow structure in the axial direction, and an elongated hole is processed in the axial direction of the inner part of the housing 7 , and a sealing device is arranged on the elongated opening to contact the inner wall of the housing 7 . There are two types of sealing devices in this specific embodiment, one is end face sealing, and the other is axial sealing. The end face seal is installed at the end p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com