Bidirectional inflow whirling current type shaft facility for flood discharge and energy dissipation in dam

A swirl type and vertical shaft technology, which is applied in the field of discharge and energy dissipation facilities of two-way inflow swirl type vertical shaft in the dam, can solve the problems of strong shaft vibration, difficult wall aeration, small discharge flow, etc., and increase energy dissipation efficiency , Avoid cavitation cavitation, increase the effect of discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

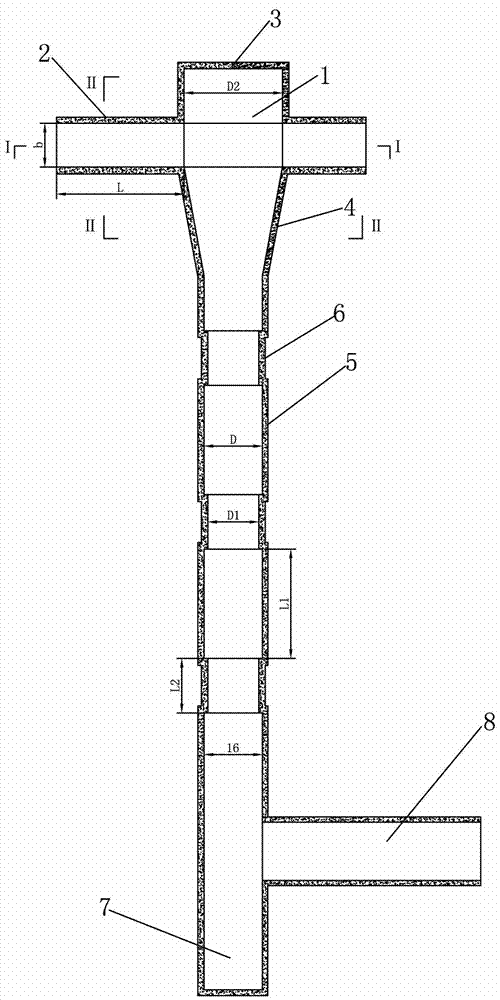

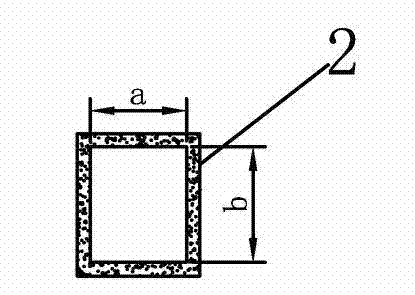

[0016] Example 1: When the flow rate is ≤25m / s and the flow rate is 2000~3000m 3 Under the condition of / s, the diameter of the shaft is D=16m, the section width of the water diversion channel is a=10m, and the height is b=12m.

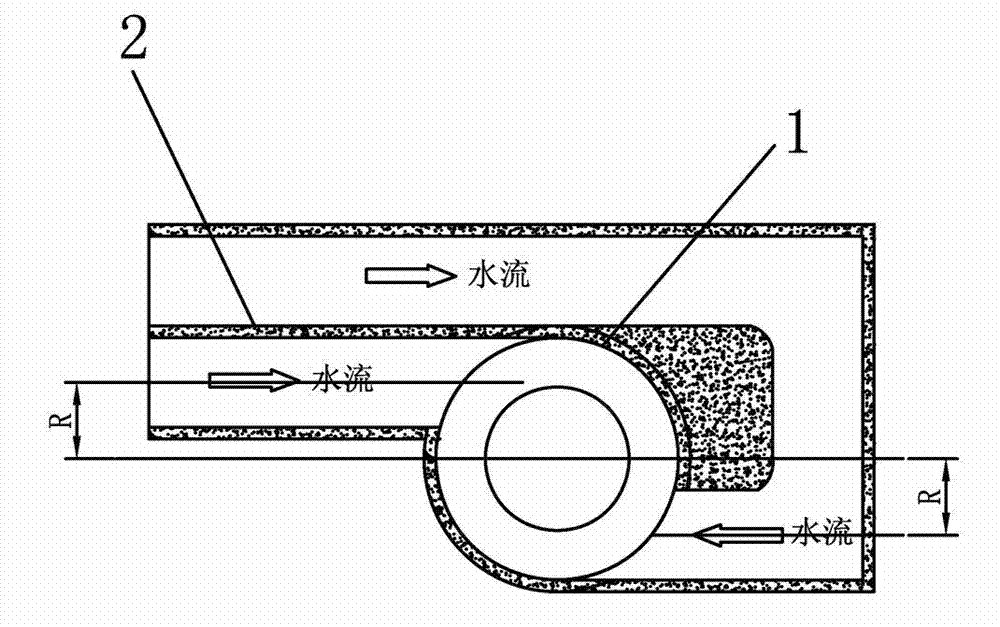

[0017] In general, the larger the eccentricity R, the better, because the larger the eccentricity, the larger the momentum distance of the water flow in the aqueduct to the shaft axis, the more fully the rotation of the water flow in the vortex chamber, and the higher the energy dissipation rate of the swirl shaft system , and the flow pattern will be better, but this often contradicts the width of the high dam. Through theoretical analysis and model tests, the eccentricity R=8.5m;

[0018] According to the test, the diameter of the vortex chamber is D2=27m, the diameter of the air hole is 0.8m, the gradient section is the connection between the vortex chamber and the shaft, and the height is 30m;

[0019] This energy dissipation facility requires a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com