Micro-ventilating membrane with air permeability changed with temperature and application for micro-ventilating membrane

A micro-breathable film and temperature-dependent technology, applied in contraceptives, chemical instruments and methods, heating appliances for therapeutic treatment, etc., to achieve the effect of expanding the application range and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

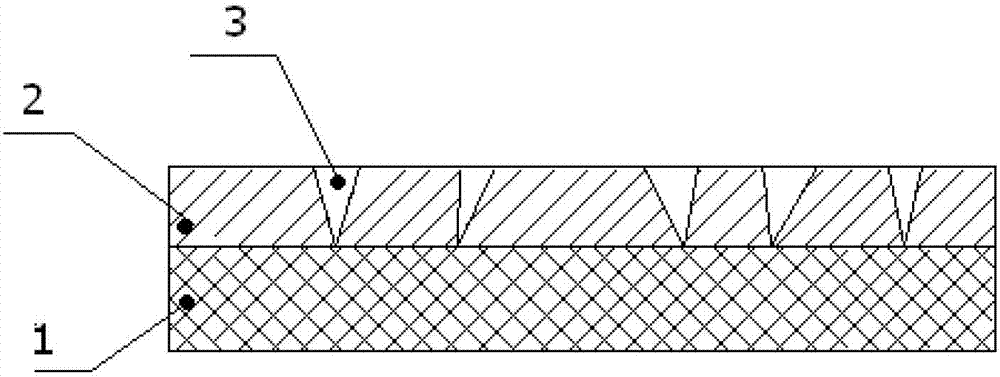

Image

Examples

Embodiment 1

[0021] Material of base fabric 1: polyester spunlace (100g / m 2 );

[0022] The material of the control layer 2: paraffin wax with a melting point of 40°C;

[0023] Preparation:

[0024] The paraffin wax is heated and melted, and then coated on the base cloth 1 by spraying to a thickness of 0.3 mm, and cooled to obtain the micro-breathable film whose air permeability varies with temperature.

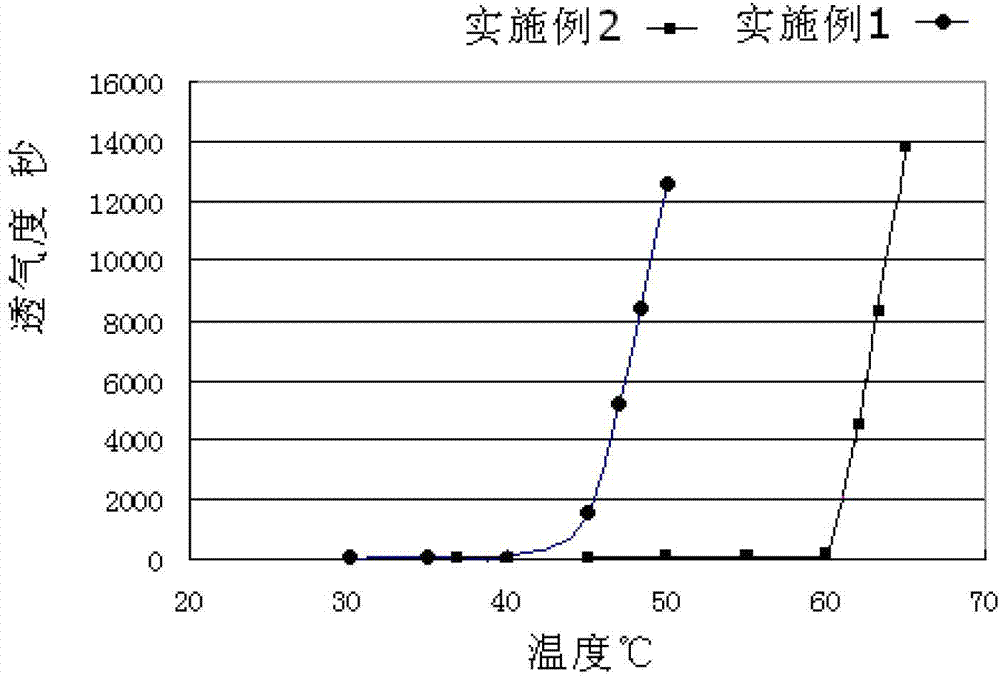

[0025] Using the method specified by Wangyan air permeability, Japanese industrial standard, JIS P 8117, for testing, see the results figure 2 .

[0026] The above experimental data show that when the temperature is lower than the melting point of paraffin, the air permeability value of the membrane is small, which means that the air permeability is large and stable. When the temperature is higher than the melting point of paraffin, the air permeability value of the membrane increases sharply, that is, the permeability becomes smaller. Therefore, the present invention can manufactur...

Embodiment 2

[0029] Material of base fabric 1: polyester spunlace (100g / m 2 ); the material of the control layer 2: paraffin wax with a melting point of 60°C;

[0030] The paraffin wax is heated and melted, and then sprayed on the polyester spunlace cloth with a coating thickness of 0.2 mm; then cooled to obtain the micro-breathable film whose air permeability changes with temperature. Using the method specified by Wang Yan's air permeability, Japanese industrial standard, JIS P8117, for testing, see the results figure 2 .

[0031] The definition of air permeability of Wangyan type: 100ml of air is driven by 0.01276 atmospheric pressure and passes through the section of the membrane to be tested at 6.424cm 2 The time required in seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com