Multistage anaerobic wastewater treatment method and special device

A wastewater treatment and special equipment technology, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of easy formation of dead angle and short flow, poor sludge activity, slow biochemical reaction rate, etc., to speed up the process of sludge granulation and improve biochemical Reaction rate, effect of improving removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

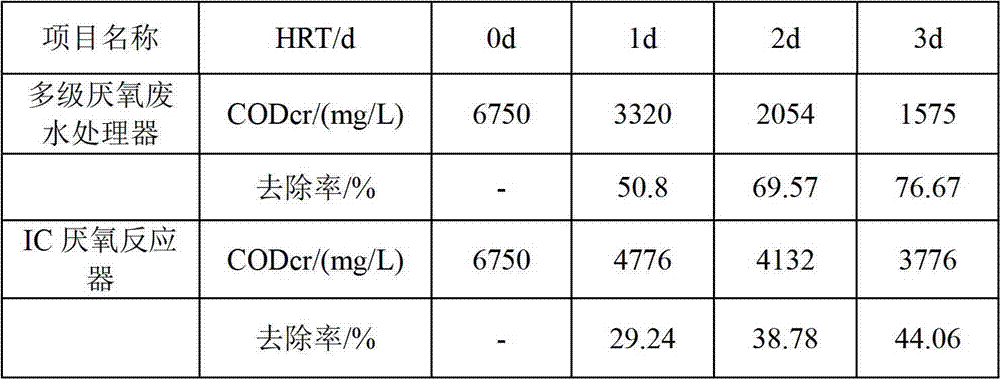

Examples

Embodiment 1

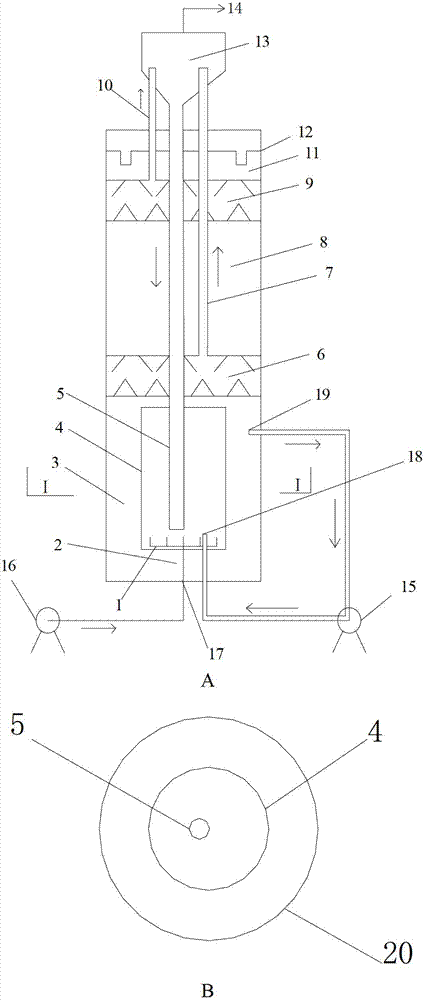

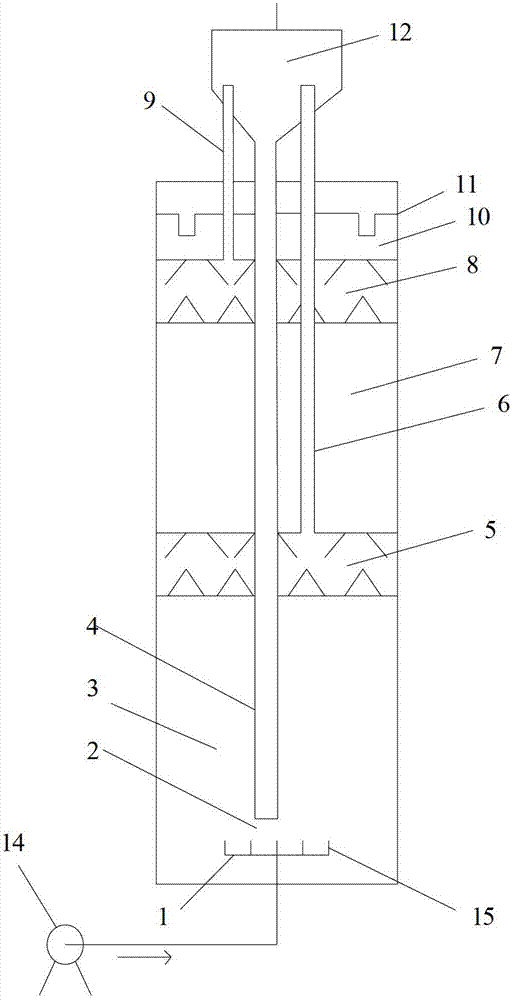

[0029] Multi-stage anaerobic wastewater treatment such as figure 1 shown.

[0030] The multi-stage anaerobic wastewater processor is divided into a fluidized bed structure anaerobic zone 3, an upflow anaerobic zone 8 and a sedimentation zone 11 from bottom to top, and the fluidized bed structure anaerobic zone 3 and the upflow anaerobic zone The oxygen zone 8 is separated by a first-stage three-phase separator 6, which is located in the middle of the anaerobic zone 3 of the fluidized bed structure and the upflow anaerobic zone 8, and is connected with the multi-stage anaerobic wastewater through the support The side wall of the processor is fixed, and the two are separated in space. The upflow anaerobic zone 8 and the sedimentation zone 11 are separated by a secondary three-phase separator 9, and the secondary three-phase separator 9 is in a liter The middle of the flow-type anaerobic zone 8 and the sedimentation zone 11 is fixed to the side wall of the multi-stage anaerobic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com