An integrated device and method for promoting anaerobic sludge granulation

An anaerobic sludge and granulation technology, applied in anaerobic digestion treatment, chemical instruments and methods, biological treatment devices, etc., can solve the problem of random addition of signal molecules, low contact efficiency between signal molecules and anaerobic sludge particles, Problems such as the growth of anaerobic sludge particles cannot be accurately controlled, so as to shorten the granulation cycle of anaerobic sludge, improve contact efficiency and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

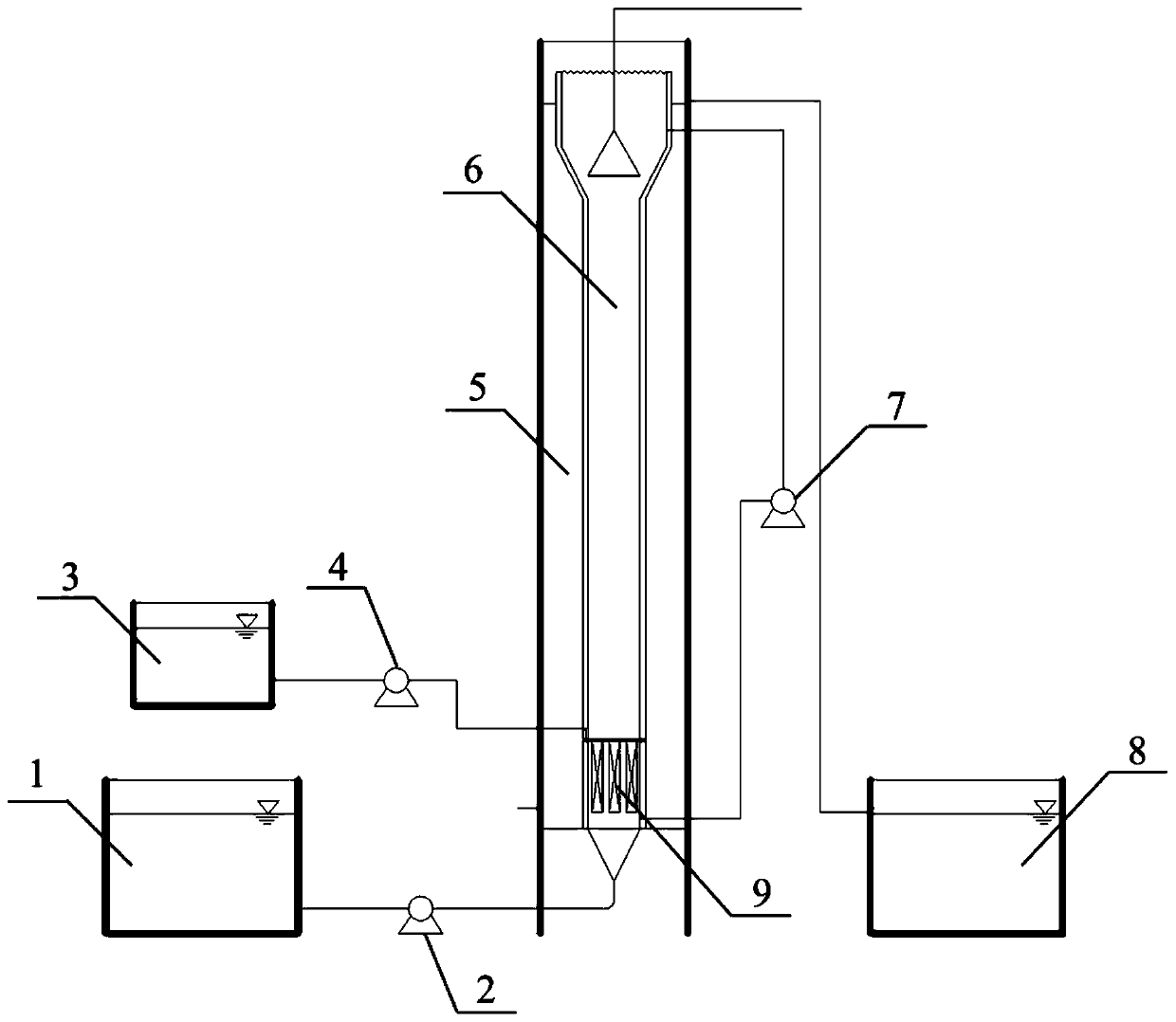

[0042] Such as figure 1 As shown, the device of the present embodiment comprises a regulating pool 1, a dosing pool 3, an EGSB reactor 6 and an outlet pool 8, the outside of the EGSB reactor is a water bath insulation layer 5, and the water outlet of the regulating pool 1 is connected with the water inlet pump 2 in turn through a pipeline. , the bottom water inlet of the EGSB reactor 6 is connected, and the water outlet of the dosing pool 3 is connected to the dosing inlet 12 of the dosing device 9 integrated in the lower part of the dosing pump 4 and the EGSB reactor 6 through pipelines successively, and the EGSB reaction The reflux water outlet at the upper end of the reactor is connected to the reflux pump and the reflux water inlet at the lower part of the EGSB reactor in turn through pipelines, and the water outlet at the top of the EGSB reactor is connected to the water outlet pool.

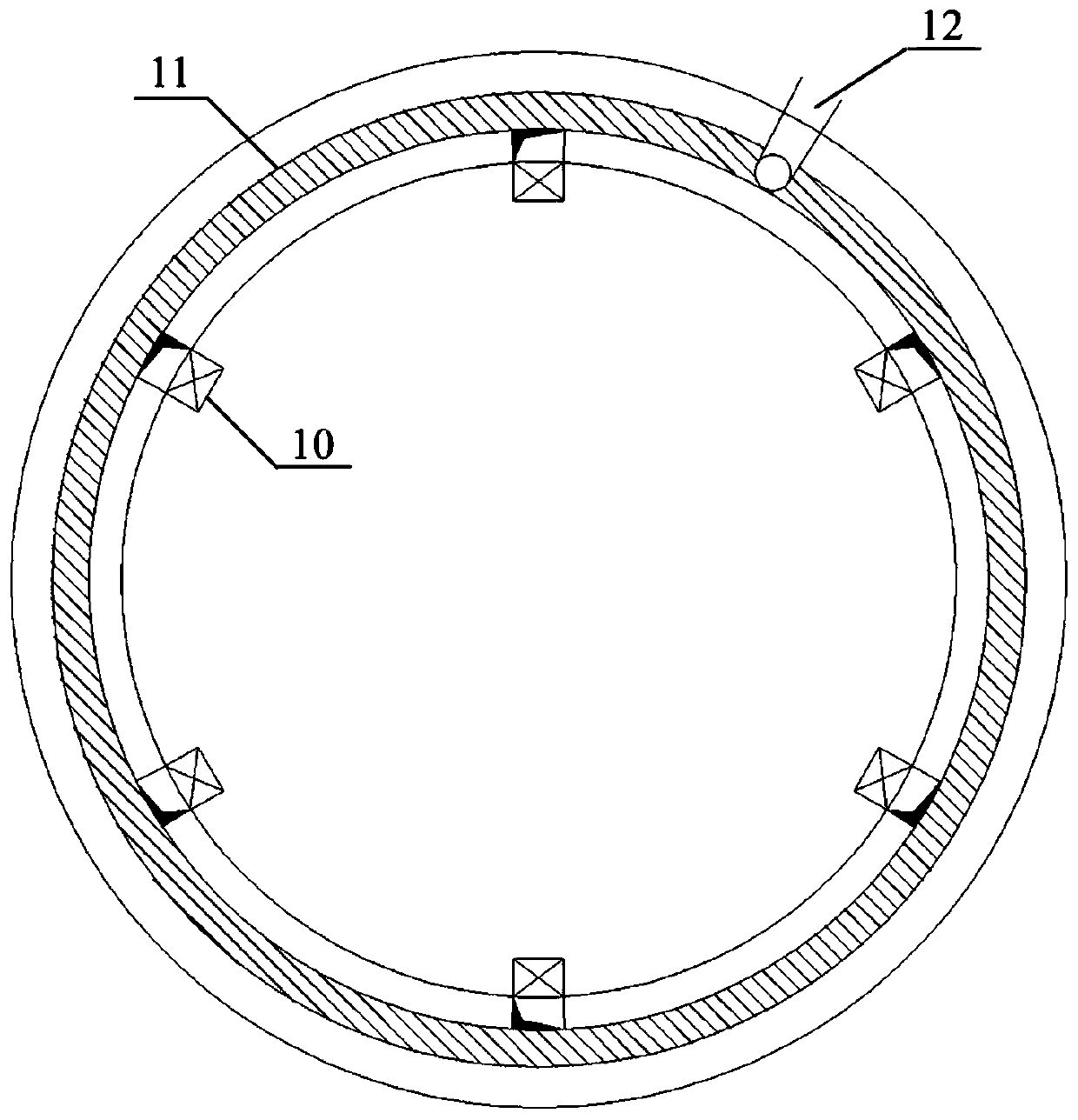

[0043] Such as figure 2 As shown, the outer circumferential surface of the cylindrica...

Embodiment 2

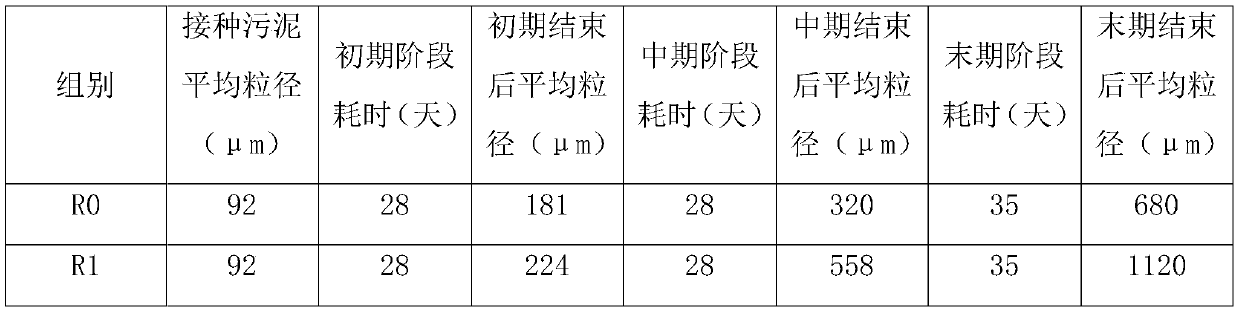

[0047] Using two sets of integrated devices of the present invention, the structures of the two sets of devices are the same, and the difference is that: one set does not add signal molecules, which is marked as R0; the other set adds signal molecules, which is marked as R1. At the same time, the same anaerobic sludge was inoculated to start granulation, and the granulation rate was compared.

[0048] The initial inoculum concentration is 30g / L, the average particle size of the sludge is 92μm; the effective volume of the integrated device is 1.87L.

[0049] The sewage is simulated organic wastewater in the laboratory, and its components are: glucose 1111-3333mg / L, ammonia nitrogen 27.8-83.3mg / L, sodium dihydrogen phosphate dihydrate 28-83.9mg / L, sodium bicarbonate 1000- 3000mg / L; trace elements are also added to the organic wastewater, and the concentrations of trace elements are respectively, the concentration of iron ions is 5.2mg / L, the concentration of calcium ions is 10.8...

Embodiment 3

[0059] Using two sets of integrated devices of the present invention, one without adding signal molecules and one with adding signal molecules, at the same time inoculate the same anaerobic sludge to start granulation, and compare the granulation rates.

[0060] The integrated device without adding signal molecules was used as the control group, denoted as R0, and the integrated device added with signal molecules was used as the experimental group, denoted as R1. The initial inoculum concentration is 30g / L, the average particle size of the sludge is 122μm; the effective volume of the integrated device is 1.87L.

[0061] The sewage is simulated organic wastewater in the laboratory, and its components are: glucose 1111-3333mg / L, ammonia nitrogen 27.8-83.3mg / L, sodium dihydrogen phosphate dihydrate 28-83.9mg / L, sodium bicarbonate 1000- 3000mg / L; trace elements are also added to the organic wastewater, and the concentrations of trace elements are respectively, the concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com