Method for filling distilled grain into fermentation pond

A technology of fermented grains and cellars, which is applied in the field of wine making, can solve the problems of large oil stewing and great influence on quality, and achieve the effects of ensuring water content, improving wine quality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

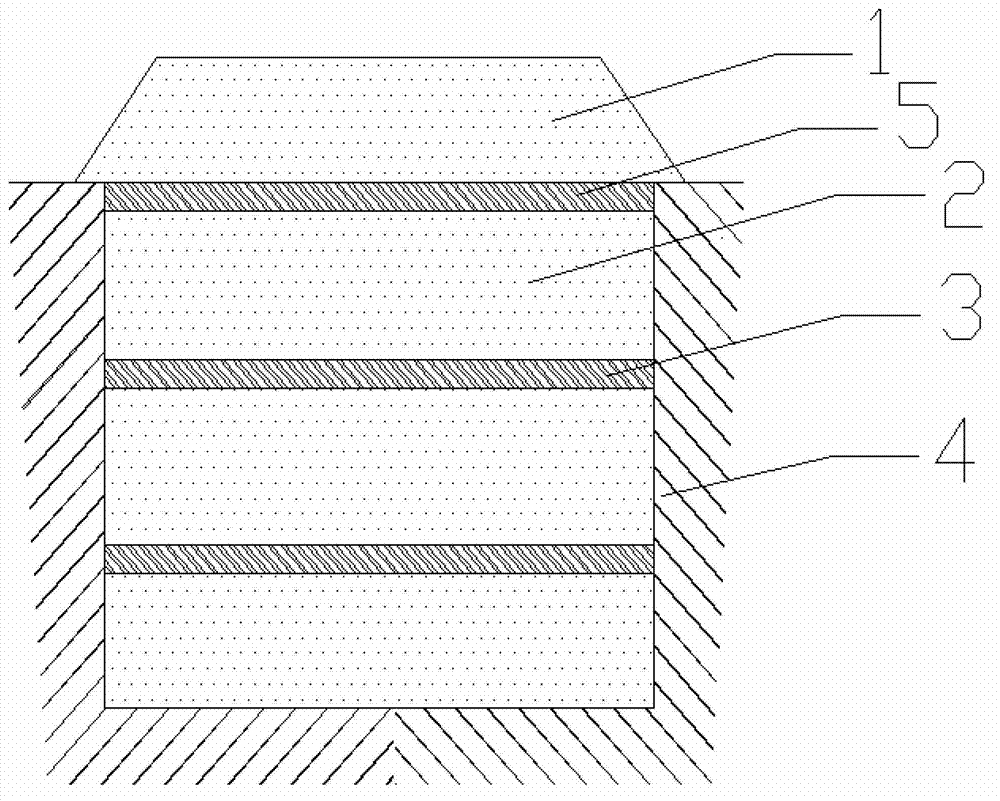

[0020] Embodiment 1 The method of the present invention is filled with fermented grains

[0021] Adopt the method of the present invention, select the mud cellar cellar pond of Luzhou-flavor liquor brewing as fermentation container, cellar pond volume is 24m 3 , of which the cellar is 400cm deep. Divide the fermented grains into two layers and fill them in (each layer is about 190cm). In the process of filling the fermented grains into the cellar, first fill the fermented grains on the mud layer at the bottom of the cellar, and then cover the middle of the pit with pit mud to form a layer of pit mud about 15 cm thick. Then cover the poor unstrained spirits on the pit mud layer until the whole pit is filled with the bad grains, and seal the top of the pit with the sealing mud, and ferment in a sealed manner for 60 days.

Embodiment 2

[0022] Embodiment 2 The method of the present invention is filled with fermented grains

[0023] Adopt the method of the present invention, select the mud cellar cellar pool of Luzhou-flavor liquor brewing as fermentation container, cellar cell volume is 24m , wherein cellar pool is deep 400cm. Divide the fermented grains into 4 layers and fill them in (each layer is about 90cm). In the process of filling the unstrained spirits into the cellar, first fill the unstrained grains on the mud layer at the bottom of the pit, and then cover the middle of the pit with pit mud to form a mud layer about 10 cm thick. Then cover the poor unstrained spirits on the pit mud layer until the whole pit is filled with the bad grains, and seal the top of the pit with the sealing mud, and ferment in a sealed manner for 60 days.

Embodiment 3

[0024] Embodiment 3 The method of the present invention is filled with fermented grains

[0025] Adopt the method of the present invention, select the mud cellar cellar pool of Luzhou-flavor liquor brewing as fermentation container, cellar cell volume is 24m , wherein cellar pool is deep 400cm. Divide the fermented grains into 8 layers and fill them in (each layer is about 45cm). In the process of filling the unstrained spirits into the cellar, first fill the unstrained grains on the mud layer at the bottom of the pit, and then cover the middle of the pit with pit mud to form a layer of pit mud about 5 cm thick. Then cover the poor unstrained spirits on the pit mud layer until the whole pit is filled with the bad grains, and seal the top of the pit with the sealing mud, and ferment in a sealed manner for 60 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com