Nano lipid carrier composition and preparation method thereof

A nano-lipid carrier and composition technology, which is applied in food science, pharmaceutical formulations, cosmetic formulations, etc., can solve problems such as solvent residues, improve particle size and dispersion performance, improve drug-carrying capacity, and increase crystal disorder. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

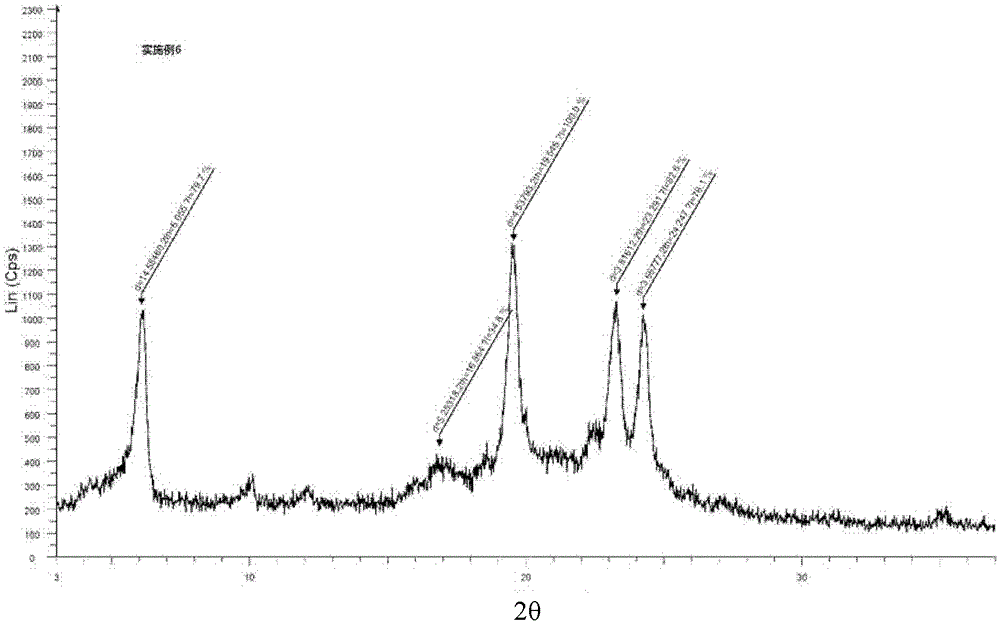

Examples

Embodiment 1

[0067] Weigh 2.8g palm oil mixture into a 100mL tall beaker, add 1.2g MCT; put the beaker in a water bath at 80℃, melt and mix with 500rpm magnetic stirring; weigh 1.9g Tween 80 dissolved in 74.1g water, and place Stir while heating on the magnetic stirrer. When the mixture is uniform and the temperature reaches 80°C, gradually add the hot surfactant aqueous solution to the mixed oil phase, and magnetically stir at 500 rpm for 10 minutes to form colostrum; place the obtained colostrum in ultrasonic cells Ultrasound on the pulverizer, power 450W, ultrasonic 3s, intermittent 3s, total 15min; quickly transfer the obtained nanoemulsion to an ice water bath at 0°C, and cool to room temperature to prepare a nanolipid carrier suspension.

[0068] Dilute a drop of the suspension into 1 mL of deionized water. The measured particle size is 144.4±1.35nm, and the PDI index is 0.214±0.012. Weigh 4.5 mg of the sample and perform the DSC program. No melting peak or crystallization peak was foun...

Embodiment 2

[0070] Weigh 2.8g hydrogenated sunflower seed oil in a 100mL tall beaker, add 1.2g MCT; put the beaker in a water bath at 80℃, melt and mix with 500rpm magnetic stirring; weigh 1.9g Tween 80 dissolved in 74.1g water, and place Stir while heating on a magnetic stirrer. When the mixture is uniform and the temperature reaches 80°C, gradually add the hot surfactant aqueous solution to the mixed oil phase, and magnetically stir at 500 rpm for 10 minutes to form colostrum; Ultrasound on the cell pulverizer, power 450W, ultrasonic 3s, intermittent 3s, a total of 15min; quickly transfer the obtained nanoemulsion to an ice water bath at 0°C and cool to room temperature to prepare a nanolipid carrier suspension.

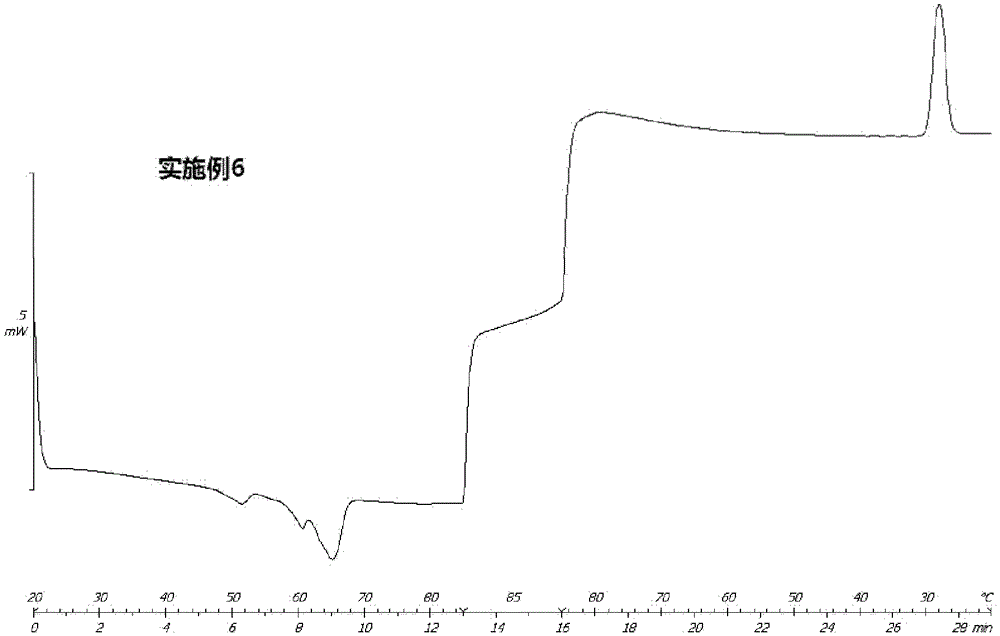

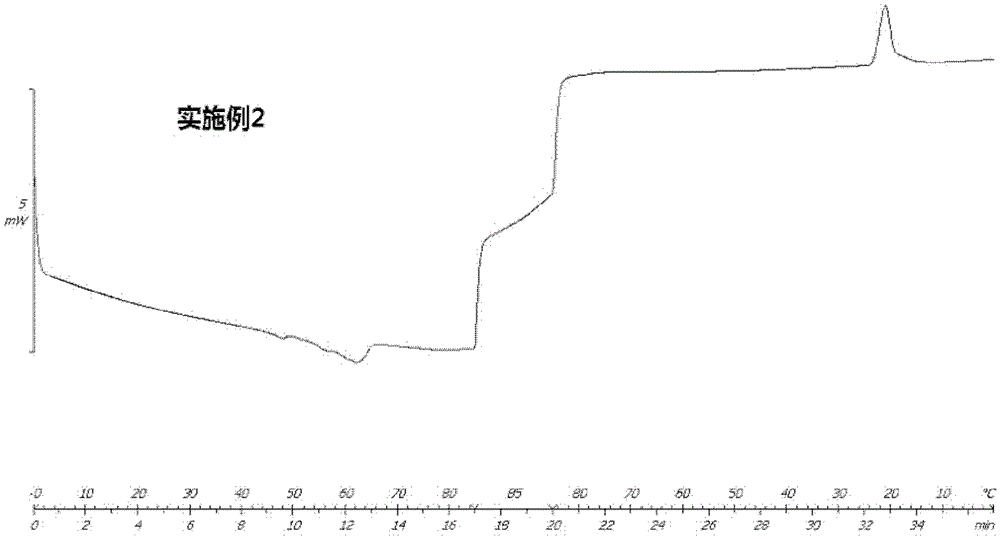

[0071] Dilute a drop of the suspension into 1 mL of deionized water, and determine the particle size to be 195.9±1.04nm and the PDI index to be 0.303±0.044. Weigh 5.32 mg of the sample and perform the DSC program. The peak melting point is 61.9°C and the peak recrystallization pe...

Embodiment 3

[0073] Weigh 7.0g hydrogenated sunflower seed oil in a 100mL tall beaker, add 3.0g MCT; put the beaker in a water bath at 80℃, melt and mix with 500rpm magnetic stirring; weigh 0.7g Tween 80 and dissolve it in 69.3g water, and place Stir while heating on a magnetic stirrer. When the mixture is uniform and the temperature reaches 80°C, gradually add the hot surfactant aqueous solution to the mixed oil phase, and magnetically stir at 500 rpm for 10 minutes to form colostrum; Ultrasound on the cell pulverizer, power 450W, ultrasonic 3s, intermittent 3s, a total of 15min; quickly transfer the obtained nanoemulsion to an ice water bath at 0°C and cool to room temperature to prepare a nanolipid carrier suspension.

[0074] Dilute a drop of the suspension into 1 mL of deionized water, and the measured particle size is 398.0±13.30nm, and the PDI index is 0.363±0.155. Weigh 4.72 mg of the sample and perform the DSC program. There are two melting point peaks, the melting point peaks are 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com