Method for increasing content of propionic acid in batch fermentation acid-producing liquid

A technology for fermentation supernatant and propionic acid, applied in microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of insufficient content, difficult to meet the needs of high-efficiency biological phosphorus removal and nitrogen removal, etc. high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

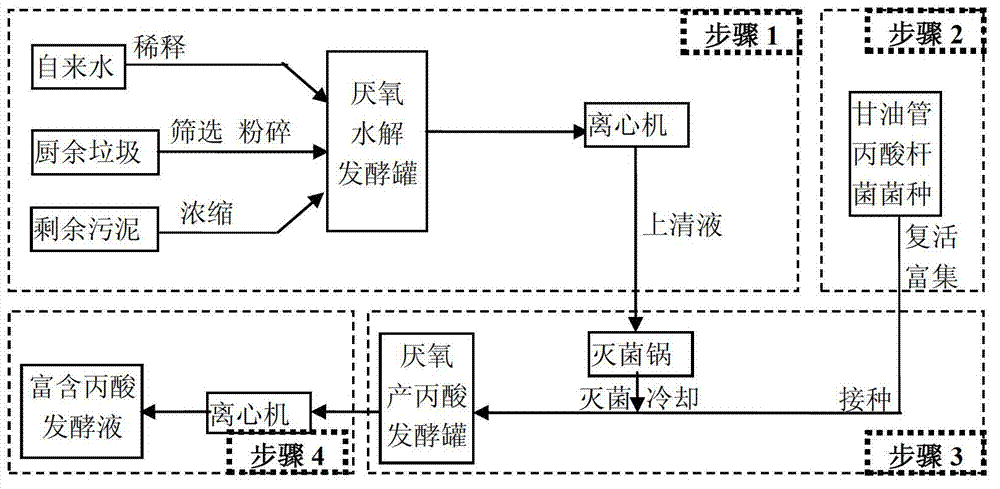

[0031] Such as figure 1 Shown:

[0032] (1) Mixture of pre-fermented sludge and kitchen waste (first-stage fermentation);

[0033] Take the crushed and sieved kitchen waste (removing chopsticks, broken bones, plastics, paper pieces, debris, etc.) 10-mesh sieve to obtain concentrated kitchen waste with a C / N of 16-20; add tap water to make the water content 80%; the main components of kitchen waste are rice, supplemented by meat and oil, rice, meat and oil The optimal dry weight ratio is 7:2:1.) 0.41L, mixed with 0.46L concentrated excess sludge (TSS 20g / L, VSS 14g / L, moisture content 98%, pH=6.84) (sludge and The dry weight ratio of kitchen waste is 0.18:1), add 1.63L tap water, and inject it into a 3L anaerobic fermentation tank (TCOD is 25g COD / L);

[0034] Fermentation at room temperature (25°C) for 2.5 days with a stirring speed of 120rpm and using Ca(OH) 2 The pH was controlled to be 8.5; the fermentation mixture was taken out and centrifuged at 3000 rpm for 5 min to ...

Embodiment 2

[0041] (1) Mixture of pre-fermented sludge and kitchen waste (first-stage fermentation);

[0042]Take 0.37L of crushed and screened kitchen waste (removing chopsticks, broken bones, plastic, paper pieces, debris, etc.), and 0.7L of concentrated residual sludge (TSS 20g / L, VSS 14g / L, moisture content 98%, pH=6.84) mixed (dry weight ratio of sludge to kitchen waste is 0.3:1), add 1.43L tap water, inject into 3L anaerobic fermentation tank (TCOD is 25g COD / L);

[0043] Fermentation at room temperature (25°C) for 2.5 days with a stirring speed of 250rpm and using Ca(OH) 2 The pH was controlled to be 8; the fermentation mixture was taken out and centrifuged at 3000 rpm for 5 min to obtain 2 L of centrifuged supernatant.

[0044] (2) Activate and enrich Propionibacterium;

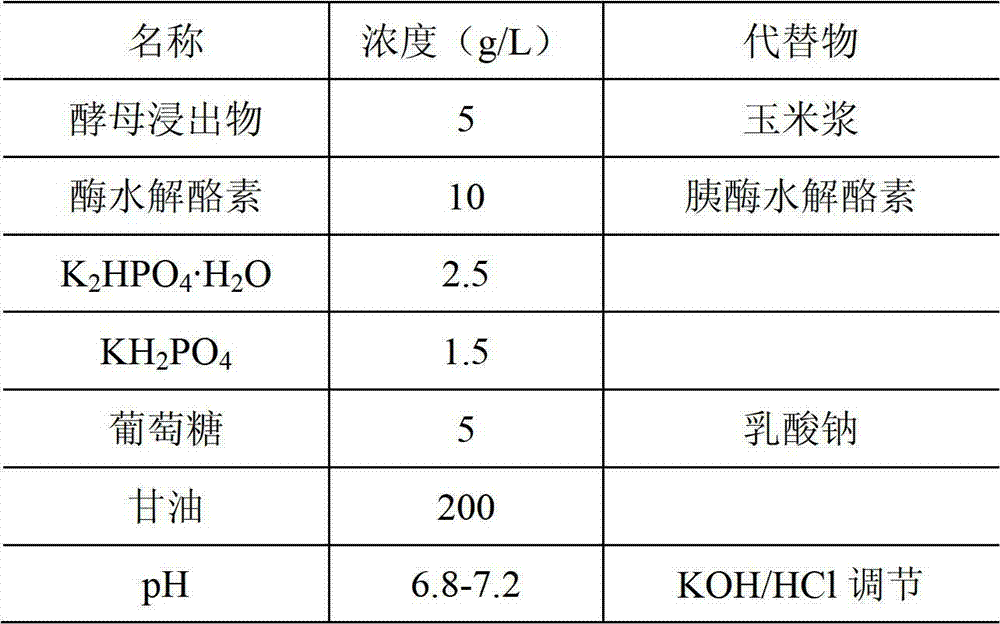

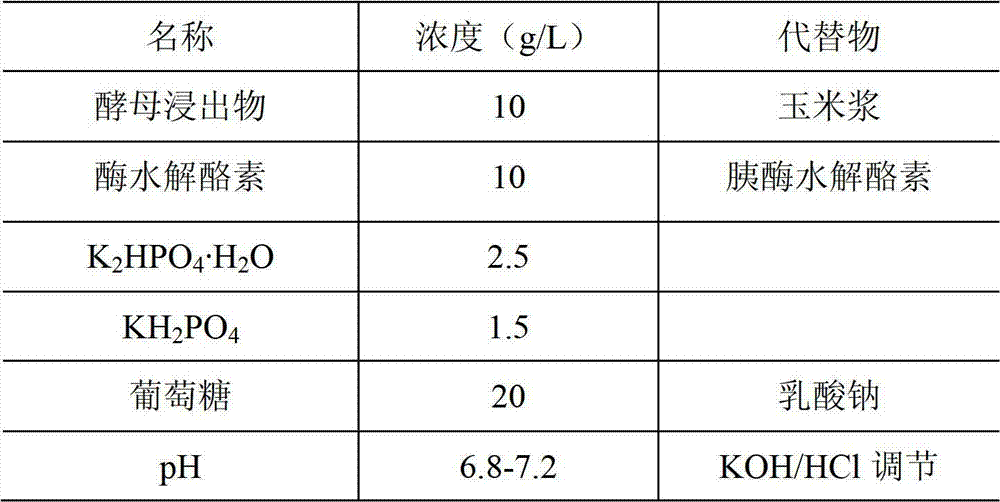

[0045] Propionibacterium (SICC1.256) was activated from the slant and then enriched and stored in 10% glycerol tube storage medium (see Table 1 for the medium formula), and the storage environment was -80°C; be...

Embodiment 3

[0050] (1) Mixture of pre-fermented sludge and kitchen waste (first-stage fermentation);

[0051] Take 0.45L of crushed and screened kitchen waste (removing chopsticks, broken bones, plastic, paper pieces, debris, etc.), and 0.22L of concentrated residual sludge (TSS 20g / L, VSS 14g / L, moisture content 98%, pH=6.84) mixed (dry weight ratio of sludge to kitchen waste is 0.08:1), add 1.83L tap water, inject into 3L anaerobic fermentation tank (TCOD is 25g COD / L);

[0052] Fermentation at room temperature (25°C) for 2.5 days with a stirring speed of 60rpm and using Ca(OH) 2 The pH was controlled to be 8; the fermentation mixture was taken out and centrifuged at 3000 rpm for 5 min to obtain 2 L of centrifuged supernatant.

[0053] (2) Activate and enrich Propionibacterium;

[0054] Propionibacterium (SICC1.256) was activated from the slant and then enriched and stored in a 15% glycerol tube storage medium (see Table 1 for the medium formula), and the storage environment was -80°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com