Underwater concreting sampler of bored pile

A technology for underwater concrete and bored cast-in-place piles, which is applied in construction, infrastructure testing, infrastructure engineering, etc., can solve problems such as inconvenient operation, hidden dangers in quality, and large economic costs, so as to avoid quality accidents and production costs. Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

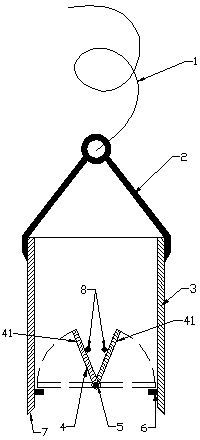

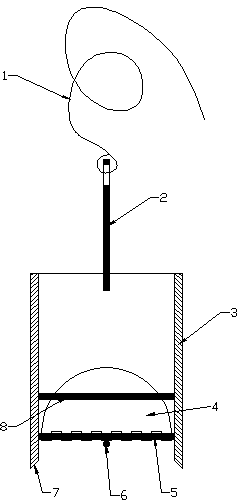

[0010] As shown in the figure, the sampler for underwater concrete pouring of bored piles includes a section of hanging rope 1. The lower end of the hanging rope is connected with a hanging beam 2. The two arms of the hanging beam and the upper wall of a cylindrical storage tube 3 Connected, the bottom of the storage cylinder 3 is provided with a shutter 4 that can be opened or closed; the shutter is composed of two semicircular door panels 41, and the bottom opening of the storage cylinder is provided with a rotating shaft 5 on the diameter, two semicircles The shaped door panels 41 are hinged on the rotating shaft 5; the inner wall of the lower end of the storage cylinder is also provided with a stop pin 6, and the edge of the semi-circular door panel 41 falls on the stop pin 6 when the shutter 4 is closed. The lower end circumference of the storage barrel 3 is provided with a cutting blade 7 with a smaller wall thickness to facilitate cutting into the concrete. A blocking ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com