Special grouting device for repairing leakage of deformation joint

A deformation joint and grouting technology, which is applied in the repair of basic structures, water conservancy projects, artificial islands, etc., can solve problems such as soft cores, affecting normal grouting, and incomplete reactions, so as to ensure the mixing ratio and mixing uniformity , Improve the effect of plugging leakage and stabilize the thoroughness of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

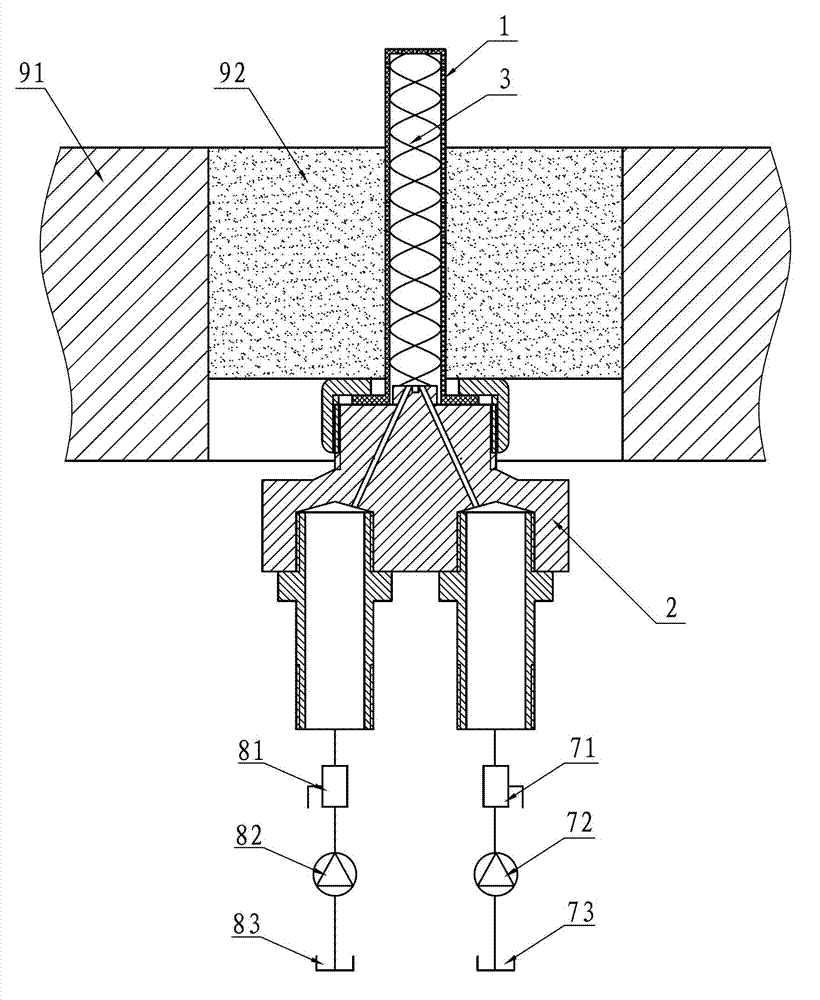

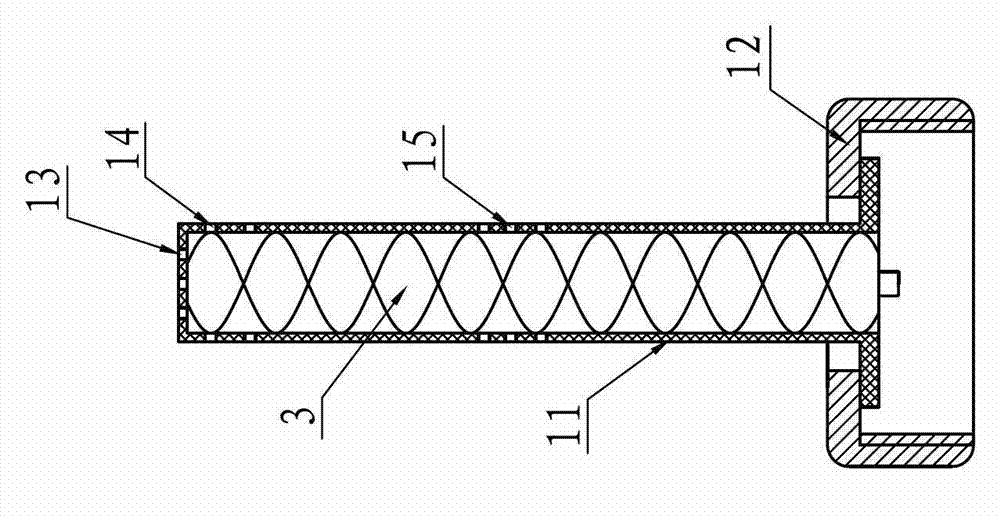

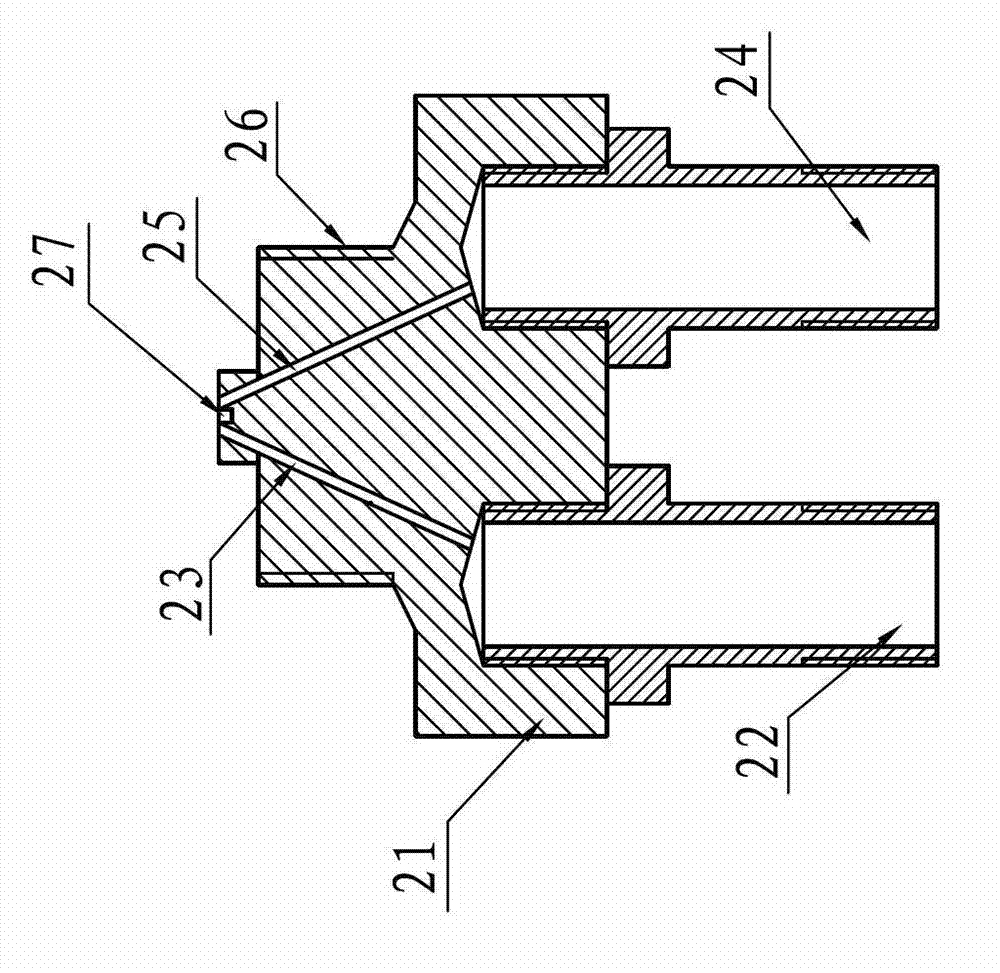

[0016] The special grouting equipment for leakage repair of deformation joints described in the present invention is as follows: figure 1 As shown, it includes stirring grouting pipe 1, grouting valve 2, positive and negative spiral stirring rod 3, water inlet valve 71, water injection pump 72, pool 73, glue inlet valve 81, grouting pump 82 and glue pool 83, The 2 stirring grouting pipes 1 such as figure 2 As shown, it includes a tube body 11, a connecting nut 12, a top slurry outlet hole 13, an upper side slurry outlet hole 14 and a lower side slurry outlet hole 15, and the connecting nut 12 is arranged at the lower end of the tube body 11. A top slurry outlet 13 is provided on the upper end surface, an upper side slurry outlet 14 is provided on the side of the upper section of the pipe body 11, and a lower side slurry outlet is provided on the side of the pipe body 11 corresponding to the middle and upper section of the deformation joint 15; the grouting valve 2 such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com