Gantry type diesel engine body

A diesel engine and gantry-type technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of low integration of diesel engine water and oil circuits, increased peripheral space of diesel engines, and the impact of compact diesel engines, so as to save installation Space, light weight, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

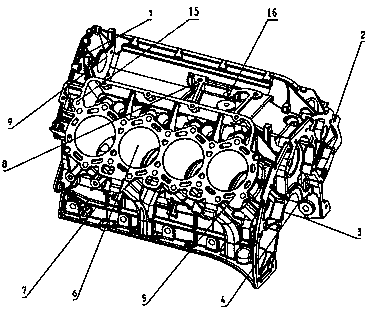

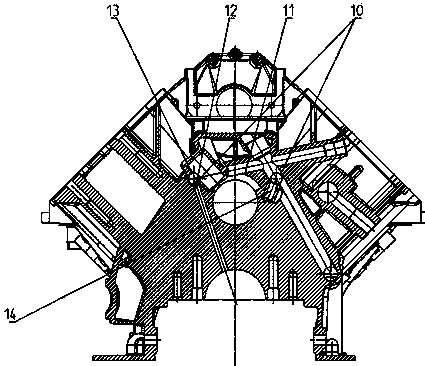

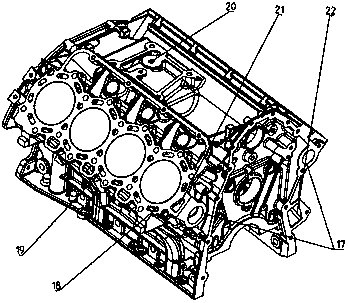

[0047] A gantry-type diesel engine body, which is composed of three parts: the mechanical structure of the body, the lubricating oil pipeline, and the cooling water pipeline, as well as several bolt holes and attachment mounting surfaces. The cylinder diameter is 101 mm, and the cylinder center distance is 116 mm;

[0048] The mechanical structure of the body: the front end of the body is the connecting surface of the transmission box; the rear end of the body is the end face of the upper flywheel shell, which is the power output end; the lower end is the connecting surface of the oil pan; the main bearing cap installation surface and the suspension bearing cap form the main bearing The hole is used to support the crankshaft; the V-shaped upper end surface is the cylinder head installation surface; the body adopts an integrated cylinder liner, without a separate cylinder liner; the key areas of the body use reinforcement ribs; The installation surface of the high-pressure pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com