Cable dividing device with anti-turning function and arranged on cable stranding machine

A wire-splitting device and anti-overturning technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of poor appearance roundness of the cable, damage to the inner bus core, damage to electrical performance, etc. Good roundness, increased frictional resistance, and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

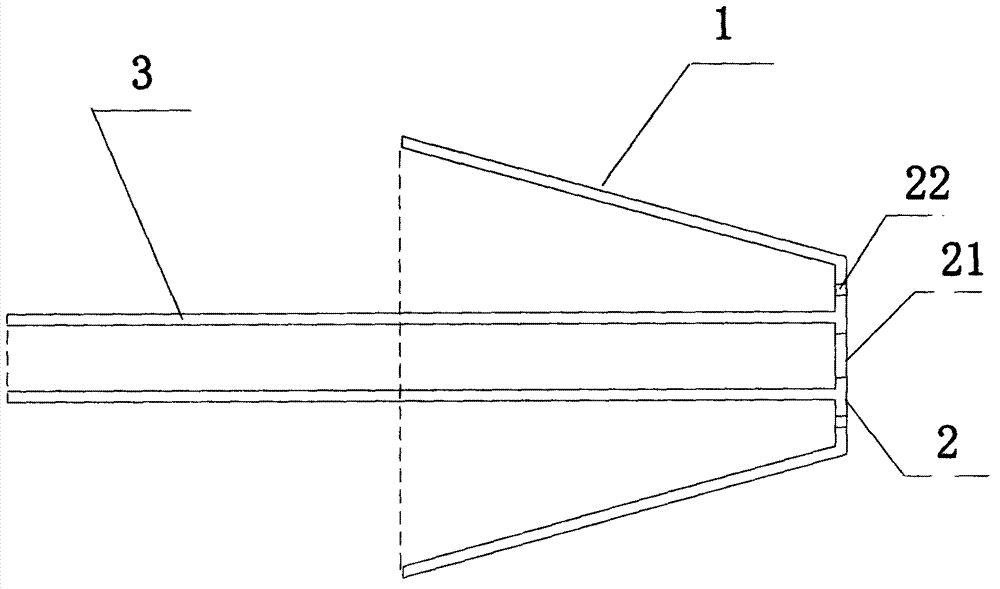

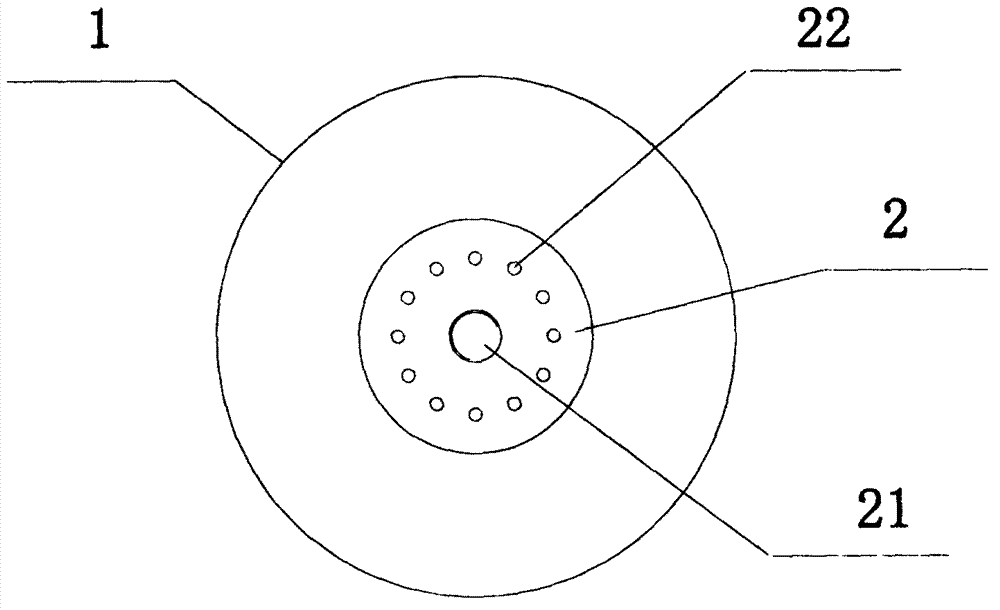

[0017] figure 1 , figure 2 As shown, a wire branching device with anti-turnover function on a cage stranding machine is characterized in that the device is set in the shape of a hollow truncated cone 1, the peripheral surface of the truncated cone 1 is smooth, and the table end of the truncated cone 1 is provided with Distribution board 2, the center of distribution board 2 is provided with a central hole 21, a number of core wire through holes 22 are arranged around the central hole 21, a hollow shaft 3 is provided at the center line of the hollow conical truncated cone 1, and the hollow shaft 3 The center line coincides with the center line of the hollow truncated cone 1 , and one end of the hollow shaft 3 is fixed in the center hole 21 of the distribution board 2 . The cone angle of the hollow conical truncated cone is set to 25-35 degrees.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com