Single-contact external compressor protector

An external compressor technology, applied in thermal switch parts and other directions, can solve the problems of many parts for temperature correction, poor product reliability, complex assembly process, etc., to achieve high reliability, improve quality and use safety, The effect of easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

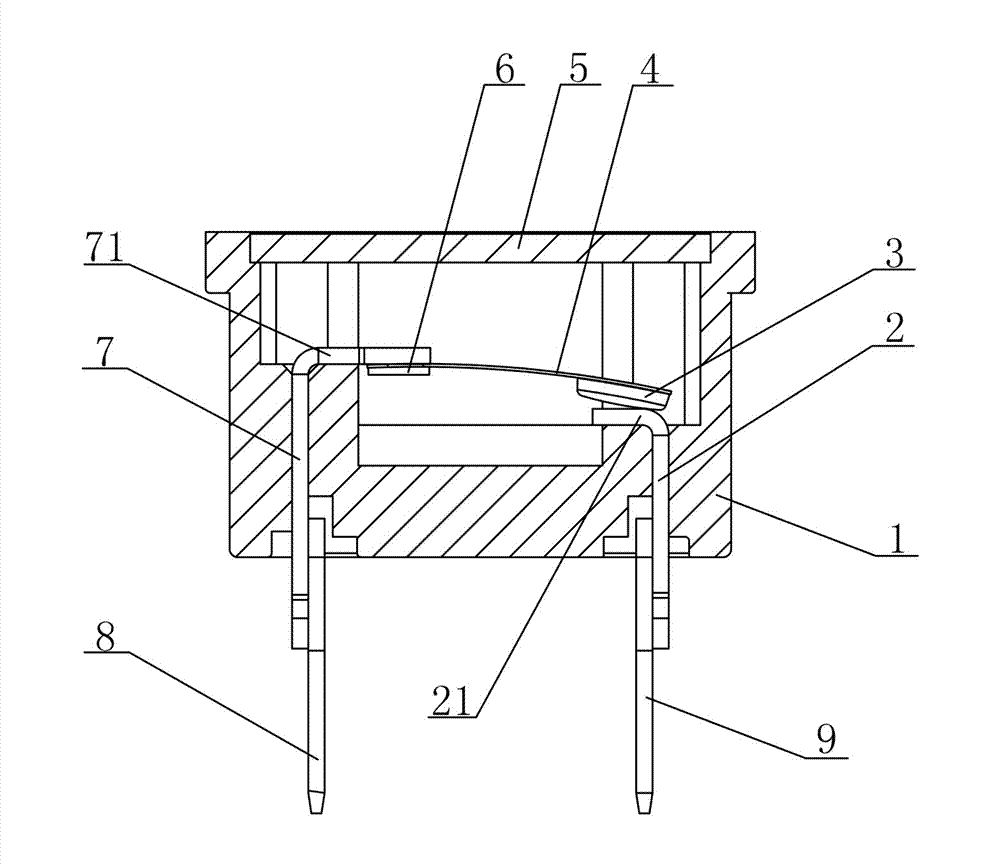

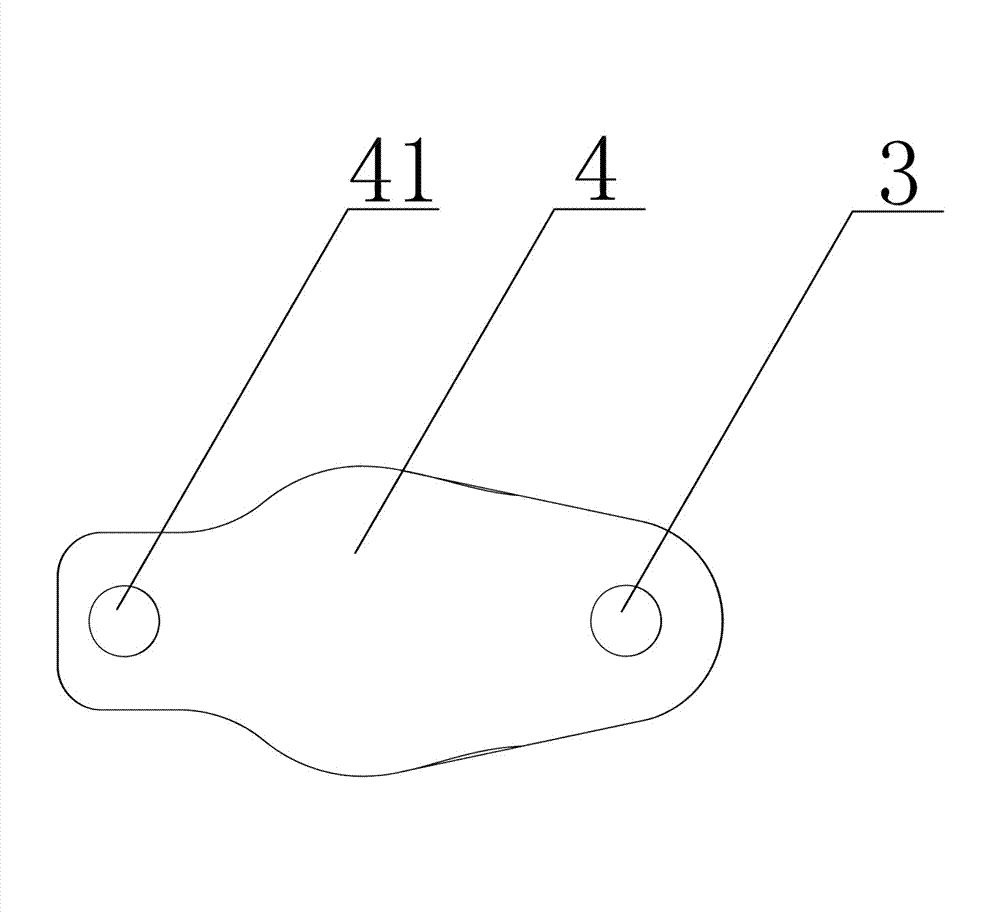

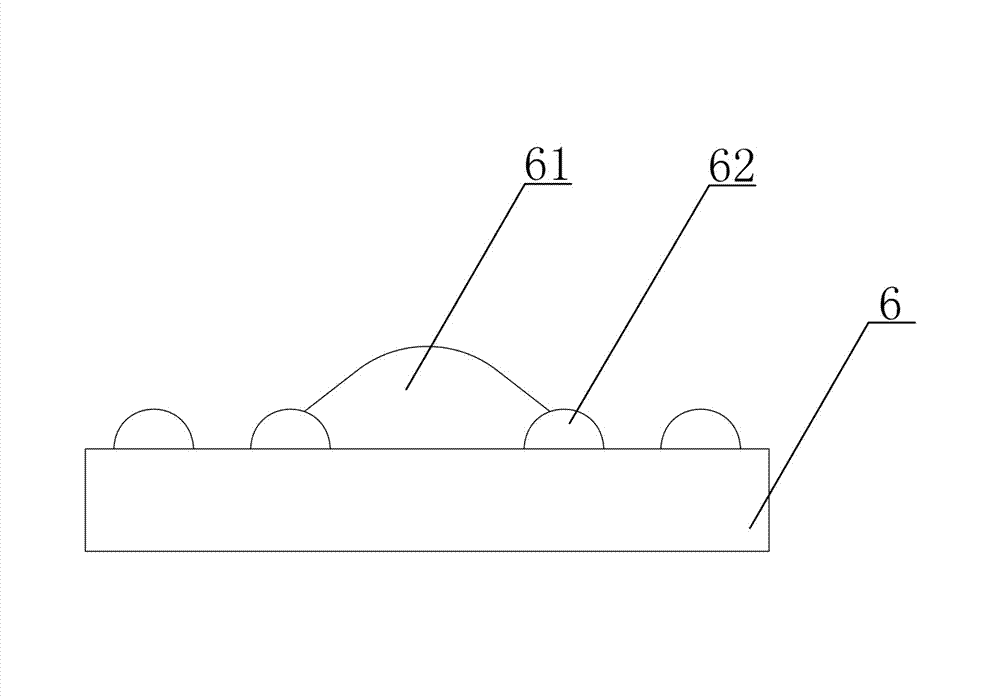

[0017] See attached figure 1 , the present invention consists of a base box 1 provided with a cover plate 5, a bimetal sheet 4, a short terminal pin 2, a long terminal pin 7, a first pin 8 and a second pin 9, and the bimetal plate 4 is provided with a The moving contact 3 is provided with an arc piece of a welding hole 41 at the other end; the short connecting pin 2 is an "L"-shaped electrical connector provided with a static contact 21; the long connecting pin 7 is provided with a cantilever 71 The "L"-shaped electrical connector; one end of the short terminal pin 2 and the long terminal pin 7 is riveted in the cavity of the base box 1, and the cover plate 5 is buckled on the base box 1 to form a sealed cavity. The other end of the pin 2 and the long terminal pin 7 protrudes from the base box 1 and is welded with the first pin 8 and the second pin 9 respectively; one end of the bimetal sheet 4 is connected to the cantilever 71 of the long terminal pin 7 through the welding ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com