An electric motor arrangement and method of controlling thereof

A motor and controller technology, which is used in motor generator control, electronic commutation motor control, and DC motor deceleration devices, etc., can solve the problems of high cost and large size of energy transfer resistors, and achieve the effect of effectively controlling short circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

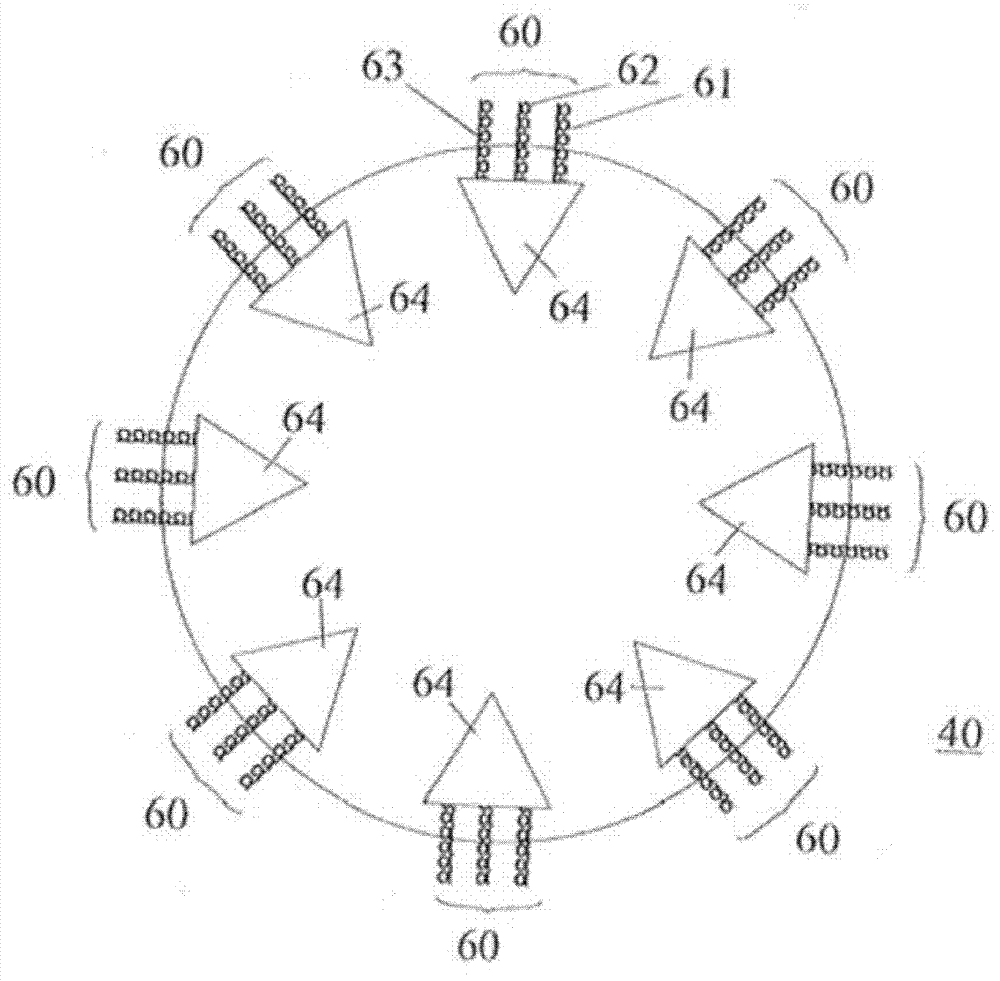

[0024] The specific embodiment described in the present invention is a permanent magnet synchronous motor for use in a wheel, that is, an in-wheel motor. However, the present invention can also be applied to other types of permanent magnet synchronous motors, as is well known to those skilled in the art. This type of electric motor has a set of coils which is part of a stator for mounting to a vehicle, axially surrounded by a rotor with a set of magnets for mounting to a wheel. Furthermore, some aspects of the present invention are applicable to a device having a rotor self-fitted into an axially surrounding coil.

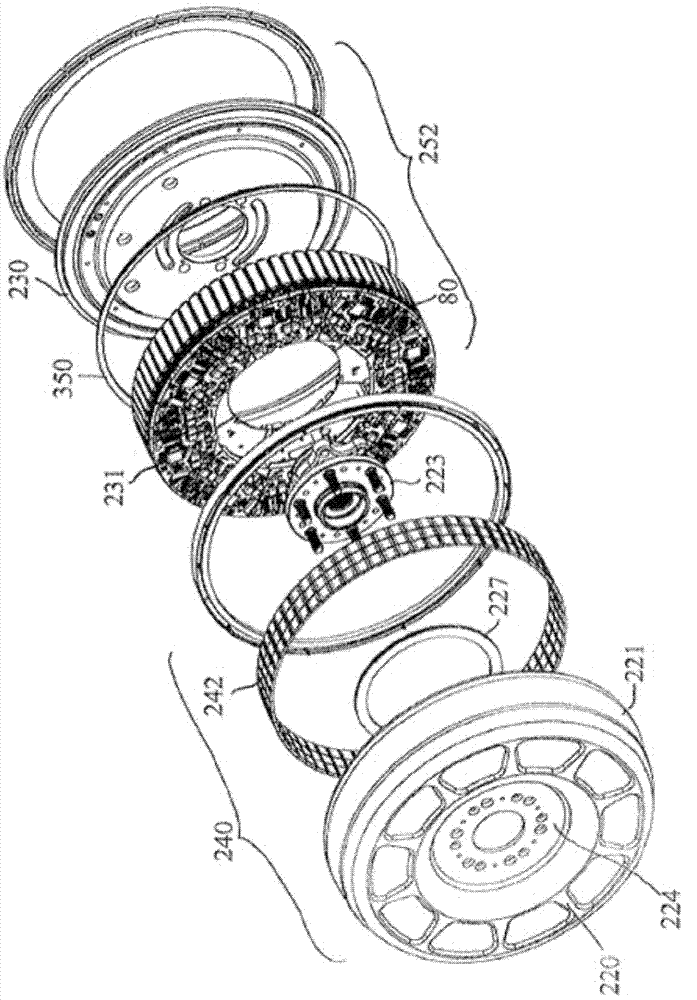

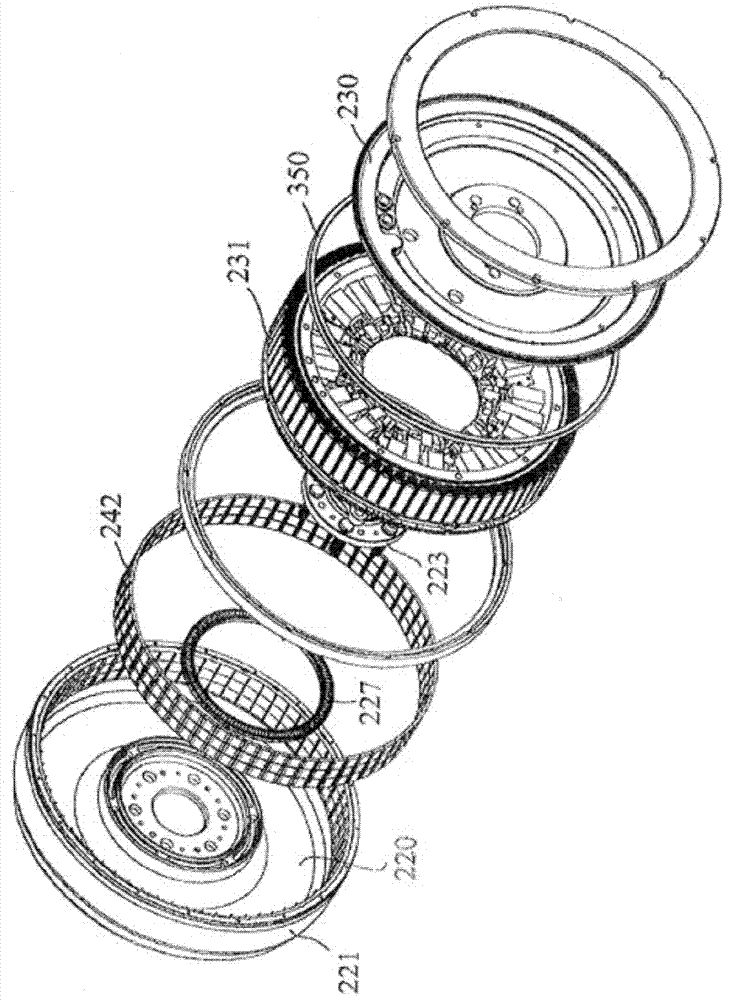

[0025] The physical device of the concrete implementation of the present invention can refer to figure 1 with figure 2 to be best understood. The device may be described as an electric motor with built-in electronics and bearings, or when the device is constructed to accommodate separate wheels, it may also be described as a hub motor or hub drive. However, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com