Atomizing nozzle for spraying granulation

A technology of atomizing nozzles and spray granulation, which is applied in the direction of spraying devices, spraying devices, etc., to achieve the effect of solving uncontrollability and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

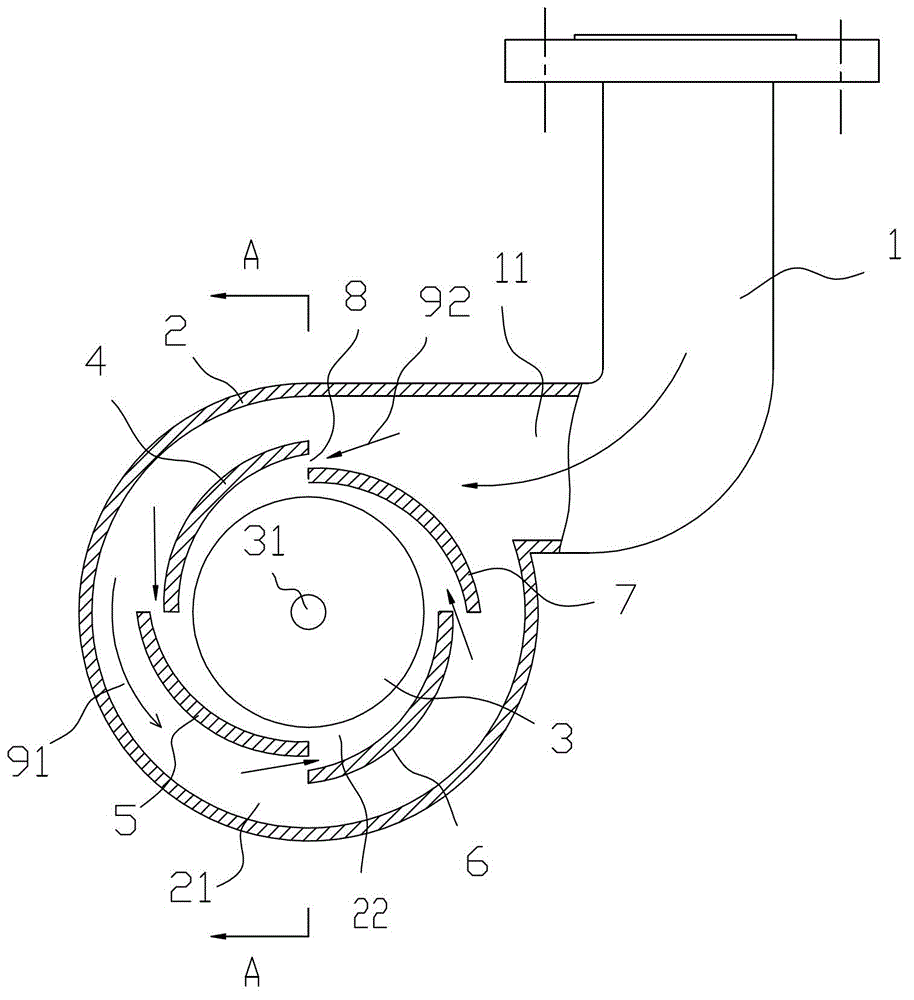

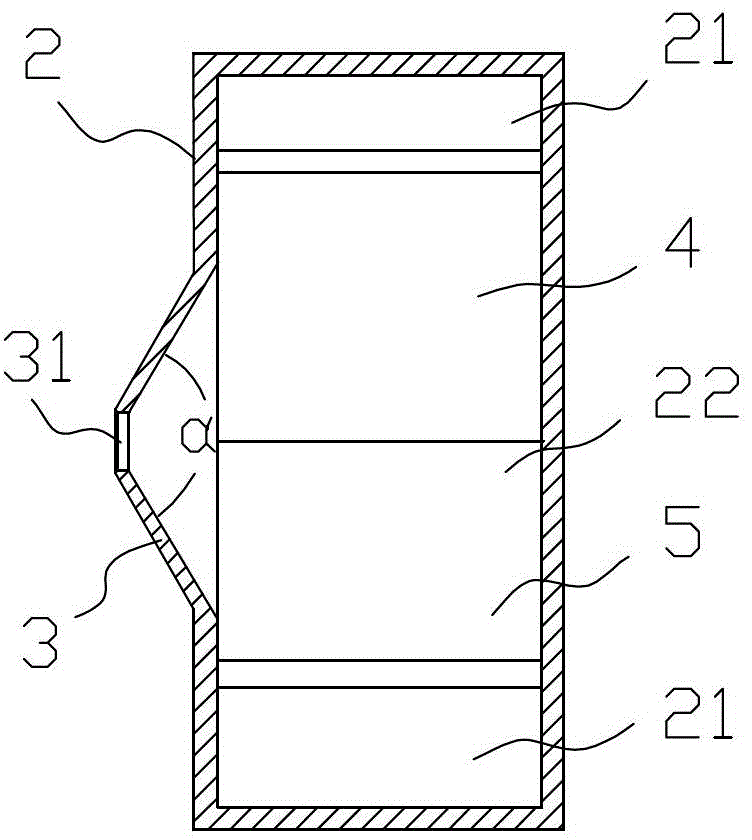

[0011] The structure of the present invention is as figure 1 and 2 As shown, it includes a feed pipe 1, an injection chamber 2 and an injection port 31. The injection chamber 2 is annular, and several arc-shaped guide vanes 4, 5, 6, 7 are arranged along the circumferential direction in the chamber 2. The cavity is divided into inner and outer guide chambers 21 and 22. The horizontal section 11 of the feed pipe 1 communicates with the outer guide chamber 21 in the tangential direction, and the front end of each guide piece is along the tangential direction of the material flow. Embedded in the outer guide cavity 21 on the outside of the front guide piece, so that the gap between the front and rear guide pieces forms the feed port 8 of the inner guide cavity 22; one axial side of the inner guide cavity 22 is provided with an outward convex Start with a conical compression cavity 3 , the taper α of the compression cavity 3 is 120° to 150°, and the injection port 31 is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com