Method for batch synthesis of rare earth nano oxide granular material

A technology of nanometer oxides and granular materials, which is applied in the preparation/processing of rare earth metal oxides/hydroxides, rare earth metal compounds, and lanthanide oxides/hydroxides, etc., can solve the application demand gap of nanometer rare earth oxides and other problems, to achieve the effect of solving uncontrollable particles and agglomeration, short and easy process flow, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

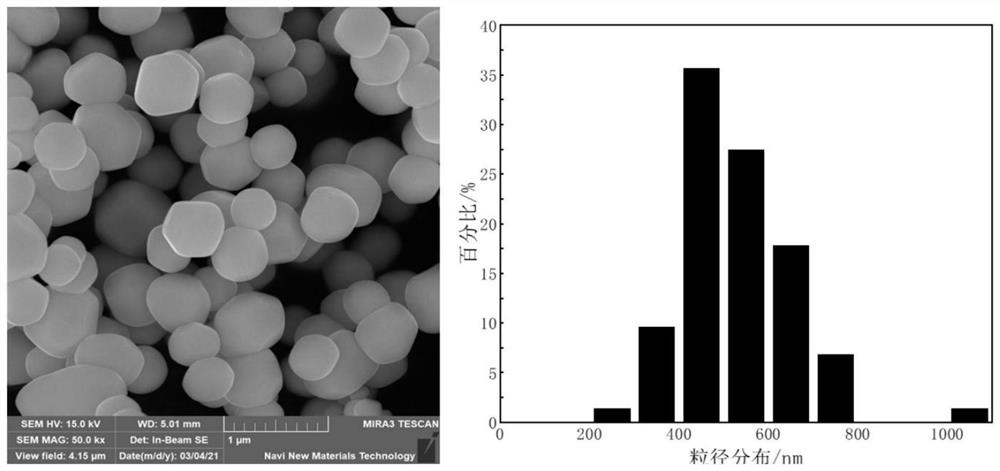

Embodiment 1

[0036]Take 10g of cerium chloride and mix it with sodium carbonate and grind it into a uniform powder, wherein the sodium chloride ratio is 1:2 and 1:1. The powder was placed in a muffle furnace, the temperature was raised to 900°C at a rate of 5°C / min, the heat treatment time was 3 hours, and the temperature was lowered to room temperature. Remove the white sample.

[0037] Take 10g of cerium chloride and mix it with sodium bicarbonate and grind it into a uniform powder, wherein the sodium chloride ratio is 1:2 and 1:1. The powder was placed in a muffle furnace, the temperature was raised to 900°C at a rate of 5°C / min, the heat treatment time was 3 hours, and the temperature was lowered to room temperature. Remove the white sample.

[0038] The specific sample number of this experiment is shown in Table 1.

[0039] Table 1

[0040] Sample No. experimental reagent sodium chloride ratio 1 Cerium Chloride and Sodium Carbonate 1:2 2 Cerium Chloride ...

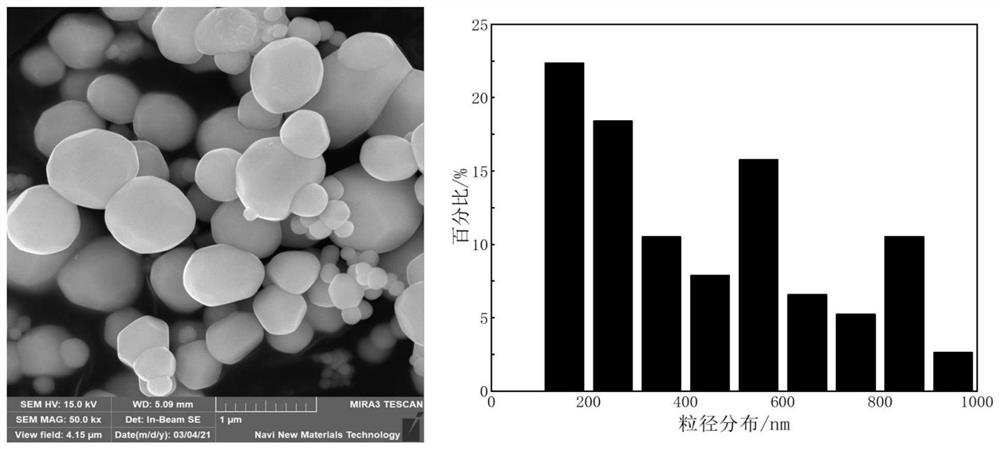

Embodiment 2

[0043] Take 10g of cerium chloride and mix it with potassium carbonate and grind it into a uniform powder, wherein the potassium chloride ratio is 2:1 and 1:1. The powder was placed in a muffle furnace, the temperature was raised to 900°C at a rate of 5°C / min, the heat treatment time was 3 hours, and the temperature was lowered to room temperature. Remove the white sample.

[0044] Take 10g of cerium chloride and mix it with potassium bicarbonate and grind it into a uniform powder, wherein the potassium chloride ratio is 2:1 and 1:1. The powder was placed in a muffle furnace, the temperature was raised to 900°C at a rate of 5°C / min, the heat treatment time was 3 hours, and the temperature was lowered to room temperature. Remove the white sample.

[0045] The specific sample number of this experiment is shown in Table 2.

[0046] Table 2

[0047] Sample No. experimental reagent Chloride Potassium Ratio 5 Cerium Chloride and Potassium Carbonate 2:1 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com