Automatic casting device for anode plate

An anode plate and driving device technology, applied in casting equipment, equipment for feeding molten metal into casting molds, equipment for supplying molten metal, etc. High strength, damage to physical health and other problems, to achieve the effects of novel mechanical structure, high production efficiency, and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

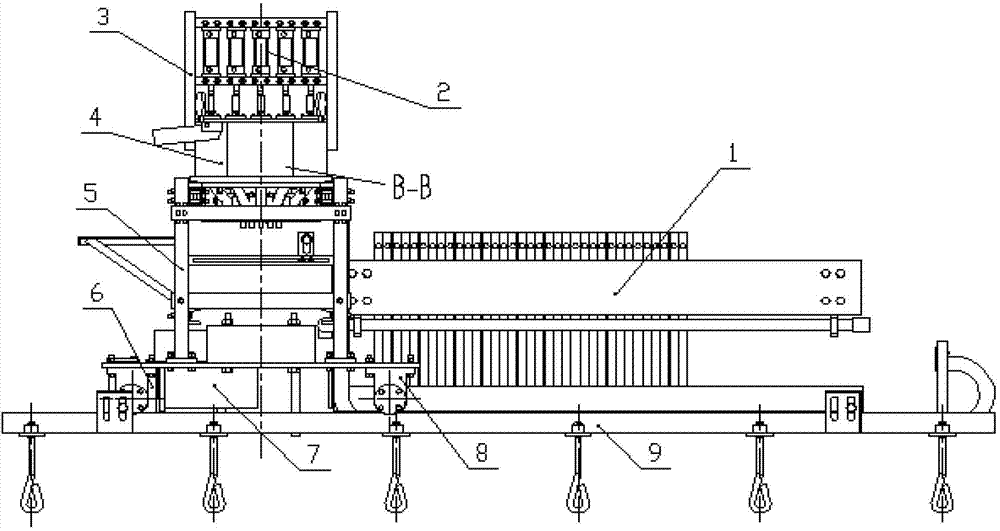

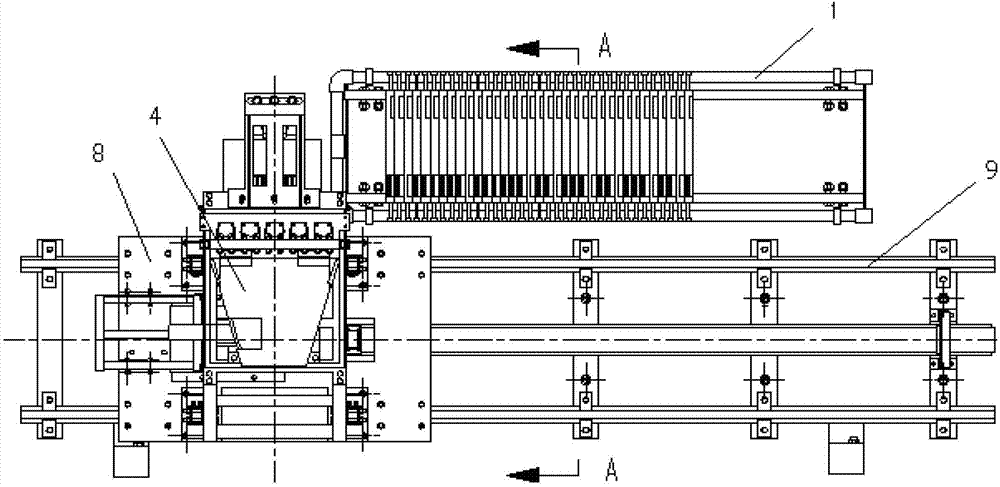

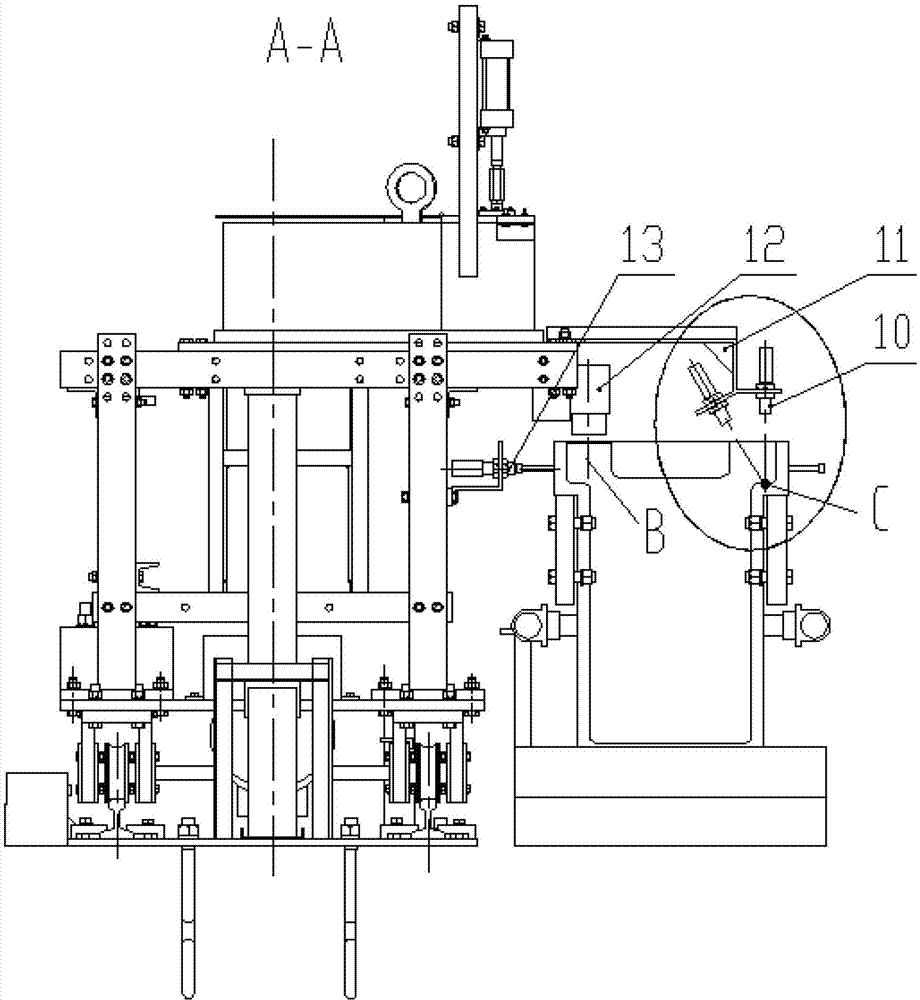

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , a trolley 8 is provided on the track 9, and a frequency conversion motor 6 is provided on the trolley 8, and the frequency conversion motor 6 is connected with the wheel transmission of the trolley 8 through a reduction box 7, and a pouring frame 5 and a multi-cavity quantitative pouring box are provided on the trolley 8 4. Each pouring chamber of the multi-cavity quantitative pouring box 4 is provided with a pouring nozzle 12, and each pouring chamber is provided with a stopper rod 14 plugged with the pouring nozzle 12 and a cylinder 2 connected with the stopper rod 14. The pouring frame 5 is provided with a cylinder frame 3, all cylinders 2 are installed on the cylinder frame 3, a multi-mode pouring mold 1 is arranged in parallel with the track 9, and the pouring nozzle 12 is docked wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com