Fixed position series assembling method of rib templates of wind turbine blade male mould

A wind power blade and assembly method technology, which is applied to auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low efficiency, labor and time, and low efficiency in serial assembly of blade male mold components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

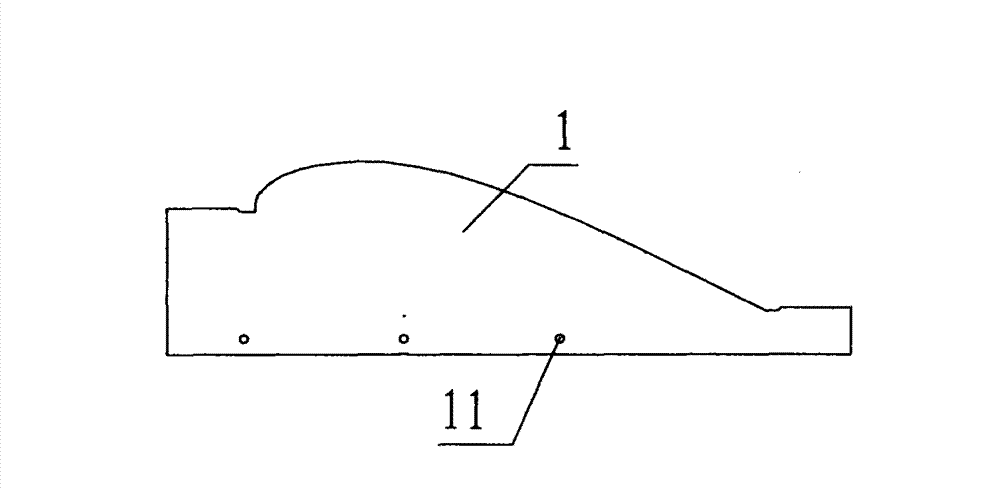

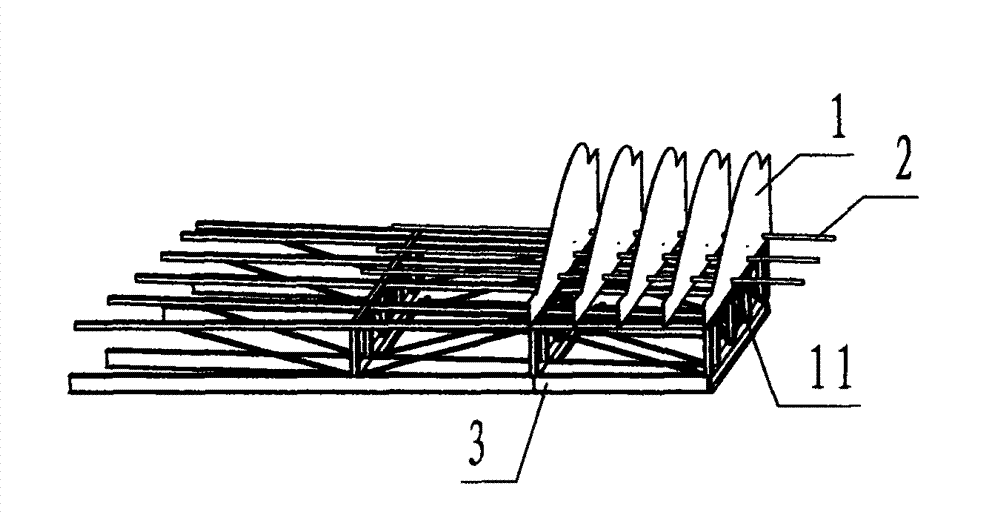

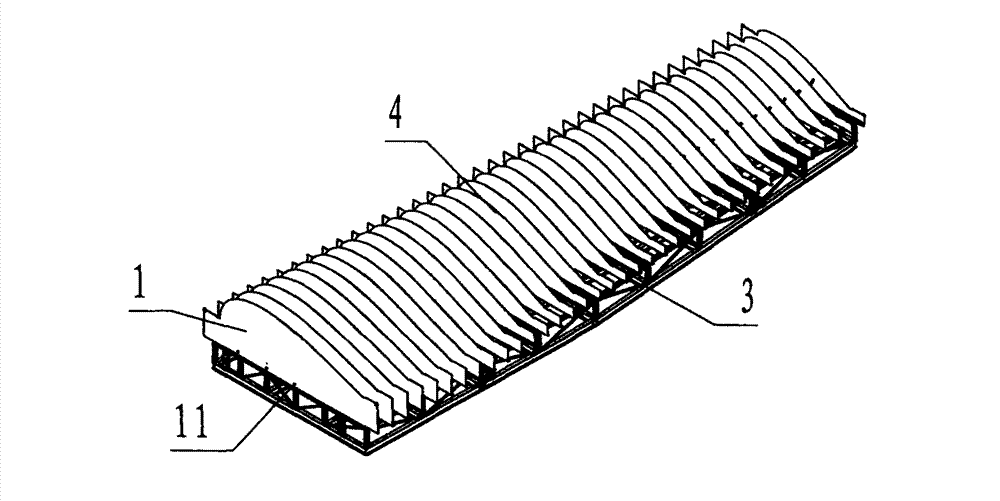

[0022] refer to Figure 1 ~ Figure 3 , a positioning series assembly method of a wind power blade male mold rib formwork of the present invention, comprising a rib formwork 1, a guide steel pipe 2, a basic steel frame 3 and a positioning series assembly method, wherein: the rib formwork 1 It is a streamlined wing-shaped steel sheet template cut by a CNC machine tool, with different top contour curves and shapes. Each wing rib template 1 is marked with a sequence number according to the arrangement and change of the top contour curve shape, which is called a serial number. , the serial number is arranged according to serial number 1, serial number 2~n serial number; the lower part of the wing rib formwork 1 is provided with three circular through holes with a diameter of φ50.2 mm, which are called serial positioning holes 11;

[0023] The guide steel pipe 2 is a circular steel pipe with an outer diameter of φ50 mm and a length of 2.5 meters;

[0024] The basic steel frame 3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com