Automatic welding system and method for truck frame

A technology of automatic welding and welding methods, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of slow workpiece circulation, single programming method, low welding efficiency, etc., and achieve safe logic design, Reasonable use of human resources, the effect of automatic welding efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

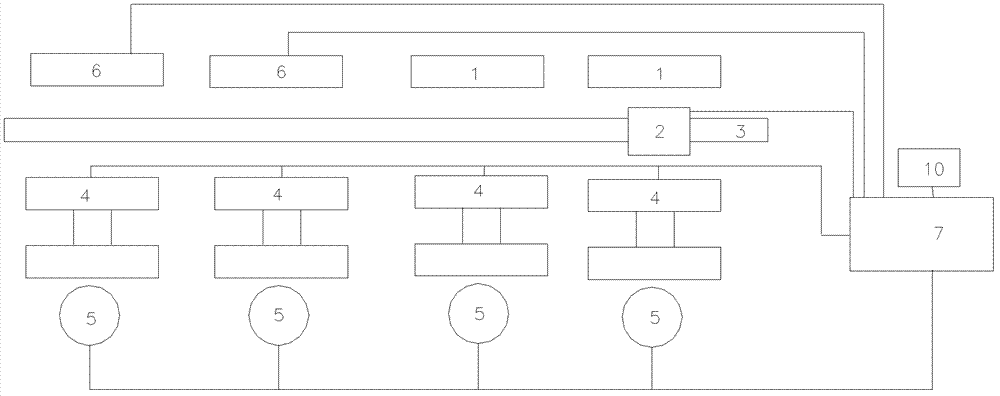

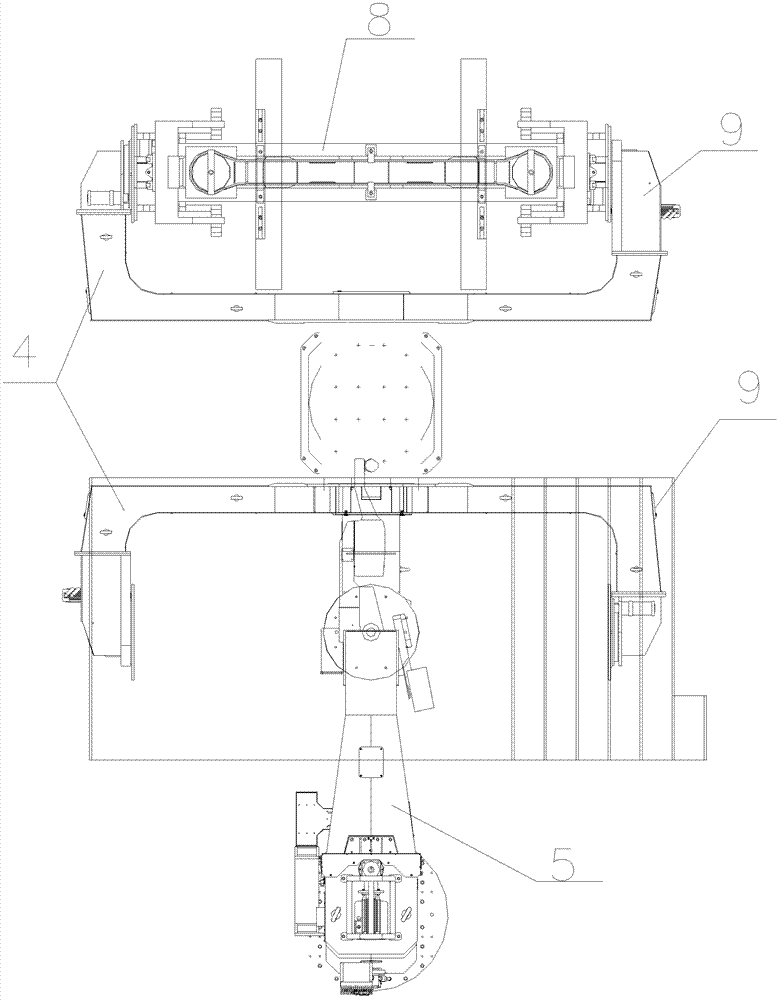

[0029] Such as figure 1 As shown, an automatic welding system for a bogie frame includes a manual storage table 1, an automatic transport trolley 2, a track 3, a clamping device 4, a welding robot 5, a buffer table 6 and a PLC main control system 7, and PLC refers to a digital Programmable logic controller for computing and operating electronic systems.

[0030] The manual storage table 1 is a manual work station for the pre-preparation of the workpiece 8 to be welded. One or more tables 1 can be set according to the process requirements of the workpiece 8 .

[0031] The automatic transport trolley 2 is used for the loading and unloading of the workpiece 8 at each process equipment and the transfer between each equipment to realize the automatic logistics function. The automatic transport trolley 2 walks on the track 3 . One or more artificia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com