Oil storage tank heating and oil-water-sand separating device for oil field

A separation device and heating device technology, applied in the direction of tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of crude oil condensation, crude oil cannot be transported, reduce costs, etc., and achieve the effects of low cost, easy removal, and system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, Structure, characteristic and effect thereof are as follows in detail.

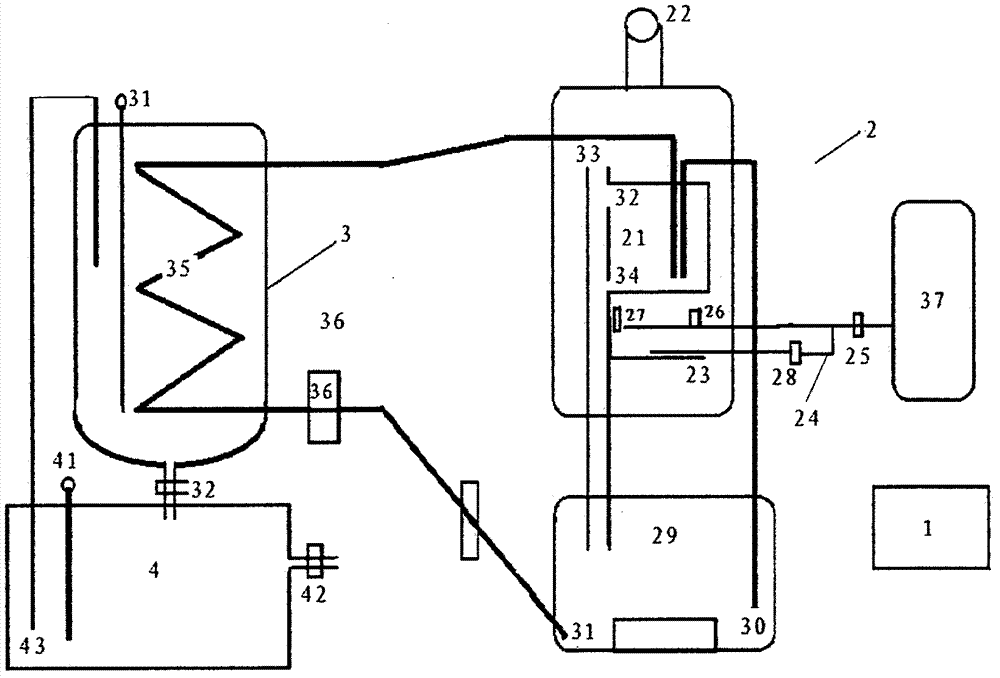

[0022] see figure 1 As shown, it is a schematic structural view of the oilfield oil storage tank heating and oil-water-sand separation device of the present invention, the device includes a general controller 1, a heating device 2, an oil storage tank 3 and a buffer tank 4, in the present invention, the general controller 1 can be a single-chip microcomputer.

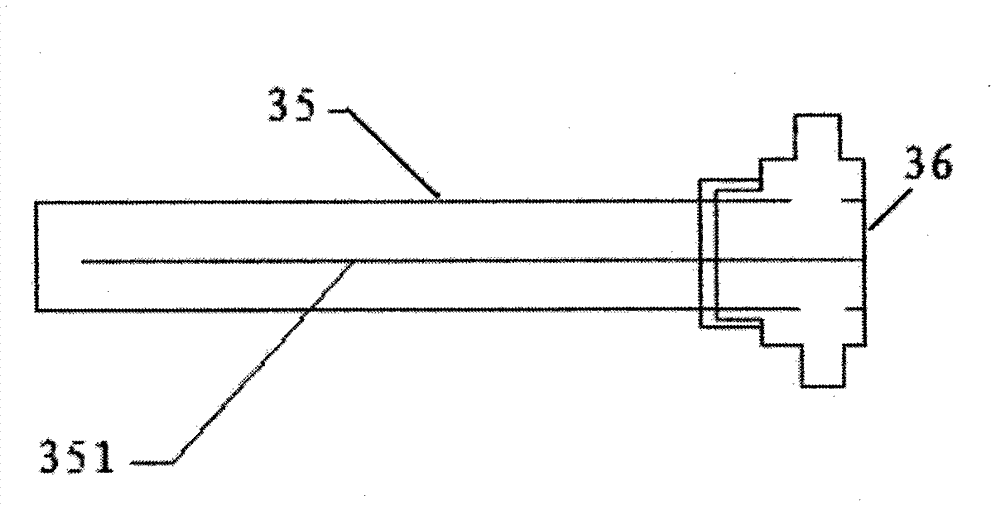

[0023] The above-mentioned heating device 2 includes, a heating tank 21, a fan 22, a burner 23, a capillary tube 24, a master control valve 25, an ignition controller 26, a fire detection sensor 27, a first electromagnetic valve 28, a liquid storage tank 29, a first exchange Pump 30, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com