Recycled concrete polyphenyl particle light thermal insulation hollow building brick and preparation method thereof

A technology of recycled concrete and polystyrene particles, which is applied in the field of non-load-bearing wall materials and its preparation, can solve the problems of occupying landfill sites, environmental pollution, etc., and achieve the effects of improving recycling, protecting the natural environment, and reducing refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

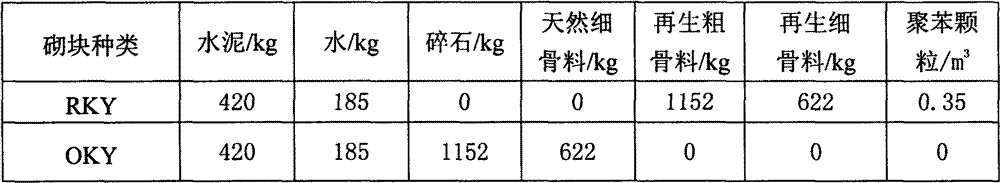

[0021] The recycled concrete polyphenyl particle lightweight thermal insulation hollow block of the present invention has raw material components and proportions in parts by weight: cement 420kg, water 185kg, recycled coarse aggregate 1152kg, recycled fine aggregate 622kg, polystyrene particles 0.35m 3 . The quality replacement rate of recycled fine aggregate is 100%.

[0022] The preparation method of the recycled concrete polystyrene particle lightweight heat-insulating hollow block includes the following steps: the raw material components and the proportion by weight are: cement 420kg, water 185kg, recycled coarse aggregate 1152kg, and recycled fine aggregate 622kg , Natural fine aggregate 0kg, polystyrene particles 0.35m 3 ,

[0023] (1) Put fine aggregate, cement, and polystyrene particles first, and mix them evenly;

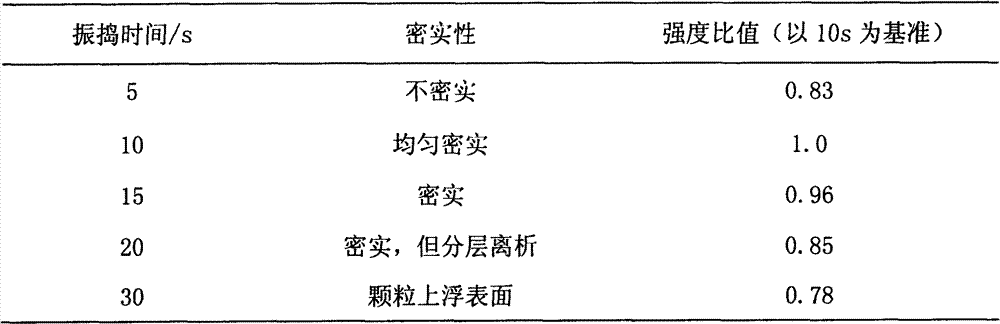

[0024] (2) While adding water, stir to make the cement paste and polyphenyl particles fully contact, the two-phase interface is completely bonded, and the cemen...

Embodiment 2

[0042] The recycled concrete polyphenyl particle lightweight heat-insulating hollow block of the present invention has raw material components and proportions by weight: cement 420kg, water 185kg, recycled coarse aggregate 1152kg, recycled fine aggregate 311kg, natural fine bone 311kg, 0.35m polystyrene particles 3 . The mass replacement rate of recycled fine aggregate is 50%.

[0043] The preparation method of the said recycled concrete polystyrene particle lightweight heat-insulating hollow block, its raw material components and proportions are: cement 420kg, water 185kg, recycled coarse aggregate 1152kg, recycled fine aggregate 311kg, natural fine Aggregate 311kg, polystyrene particles 0.35m 3 . , The implementation steps are the same as in Example 1, and the vibrating time should be controlled at about 10s. The appearance of the block is the same as in Example 1.

[0044] Table 4 is a comparative test of the ratio of raw materials between the recycled concrete polyphenyl part...

Embodiment 3

[0053] The recycled concrete polystyrene particle lightweight heat-insulating hollow block of the present invention has raw material components and proportions in parts by weight: cement 420kg, water 185kg, recycled coarse aggregate 1152kg, recycled fine aggregate 0kg, natural fine bone 622kg, 0.35m polystyrene particles 3 . The quality replacement rate of recycled fine aggregate is 0%.

[0054] In the preparation method of the recycled concrete polystyrene particle lightweight heat-insulating hollow block, its raw material components and proportions are as follows: cement 420kg, water 185kg, recycled coarse aggregate 1152kg, recycled fine aggregate 0kg, natural fine Aggregate 622kg, polystyrene particles 0.35m 3 . , The implementation steps are the same as in Example 1, the vibrating time is controlled within 10s, and the hollowness rate of the external dimensions of the block is the same as in Example 1.

[0055] Table 6 is a comparison test of the raw material ratio of the rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com