Organic phase-change energy storage material with inorganic matrix and preparation method of organic phase-change energy storage material with inorganic matrix

An energy storage material and organic phase technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of limiting the use range of phase change energy storage materials, affecting the heat storage capacity, and no phase separation, and achieving volume reduction. Small, no liquid leakage, the effect of solving liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First, mix hexadecanoic acid and octadecanoic acid in a mass ratio of 4:6, heat to a molten state, maintain the temperature at 80 °C, and stir at 800 r / min for 50-70 minutes to prepare a uniform organic phase change energy storage material Liquid eutectic mixture.

[0019] The liquid mixture was then mixed with activated alumina at a ratio of 1:3, stirred at 500 r / min for 120 minutes, and dried at 45 °C for 80 minutes to obtain a composite organic phase change energy storage material. It is determined that the solidification temperature of the composite phase change energy storage material is 66.5°C, the melting temperature is 69.1°C, the latent heat of solidification is 17.5kJ / kg, and the latent heat of fusion is 28.6kJ / kg.

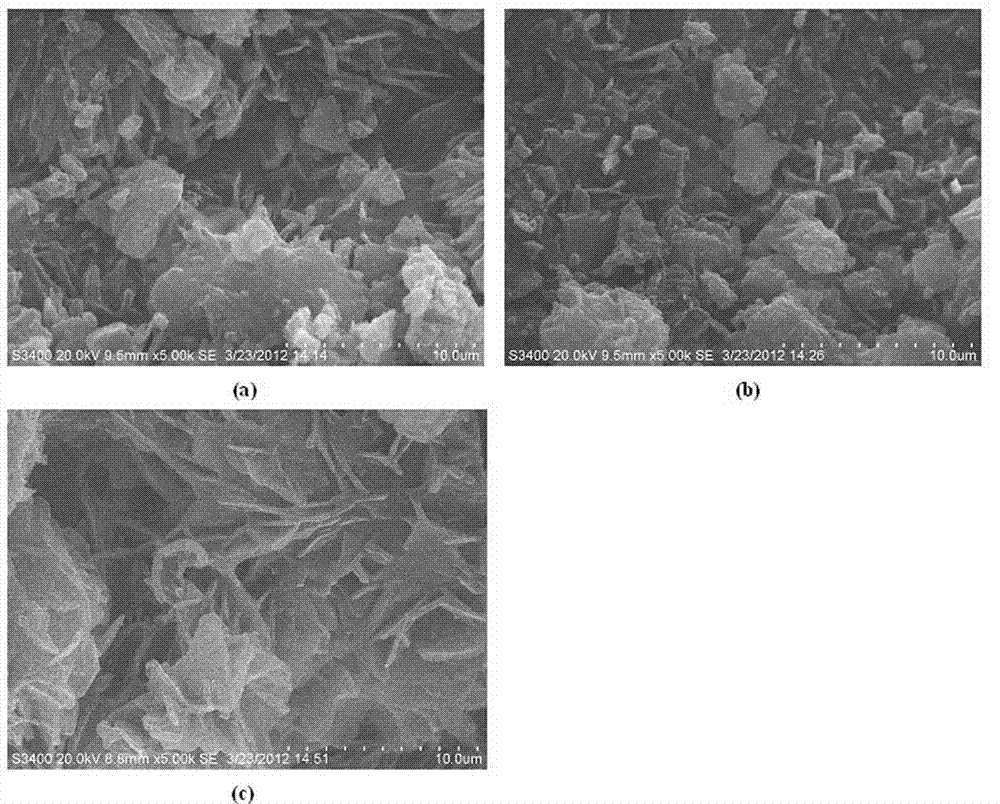

[0020] The microstructure diagram of organic phase change energy storage materials with inorganic matrix is shown in the attached figure 1 (a).

Embodiment 2

[0022] First, mix hexadecanoic acid and octadecanoic acid in a mass ratio of 5:5, heat it to a molten state, maintain the temperature at 80 °C, and stir at 800 r / min for 50-70 minutes to prepare a uniform organic phase change energy storage material Liquid eutectic mixture.

[0023] The liquid mixture was then mixed with activated alumina at a ratio of 1:2, stirred at 500 r / min for 120 minutes, and dried at 47 °C for 70 minutes to obtain a composite organic phase change energy storage material. It is determined that the solidification temperature of the composite phase change energy storage material is 63.2°C, the melting temperature is 66.8°C, the latent heat of solidification is 45.5kJ / kg, and the latent heat of fusion is 43.3kJ / kg.

[0024] The microstructure diagram of organic phase change energy storage materials with inorganic matrix is shown in the attached figure 1 (b).

Embodiment 3

[0026] First, mix hexadecanoic acid and octadecanoic acid in a mass ratio of 6:4, heat to a molten state, maintain the temperature at 80 °C, and stir at 800 r / min for 50-70 minutes to prepare a uniform organic phase change energy storage material Liquid eutectic mixture.

[0027] The liquid mixture was then mixed with activated alumina at a ratio of 1:1, stirred at 500 r / min for 120 minutes, and dried at 50 °C for 60 minutes to obtain a composite organic phase change energy storage material. It was determined that the solidification temperature of the composite phase change energy storage material was 62.1 °C, the melting temperature was 64.8 °C, the latent heat of solidification was 85.51 kJ / kg, and the latent heat of fusion was 90.2 kJ / kg.

[0028] The microstructure diagram of organic phase change energy storage materials with inorganic matrix is shown in the attached figure 1 (c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Latent heat of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com