Vermicular cast iron and manufacturing method of vermicular cast iron

A manufacturing method and technology of vermicular graphite cast iron, applied in the field of vermicular graphite cast iron and its manufacturing, can solve the problems of difficult to control the creep rate range, short decay time of creep technology, difficult to obtain high creep rate, etc., and achieve good plasticity and toughness. , The tendency of white mouth is small, and the effect of reducing the return rate

Inactive Publication Date: 2012-11-21

福建省南平市建阳区杜氏铸造有限公司

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

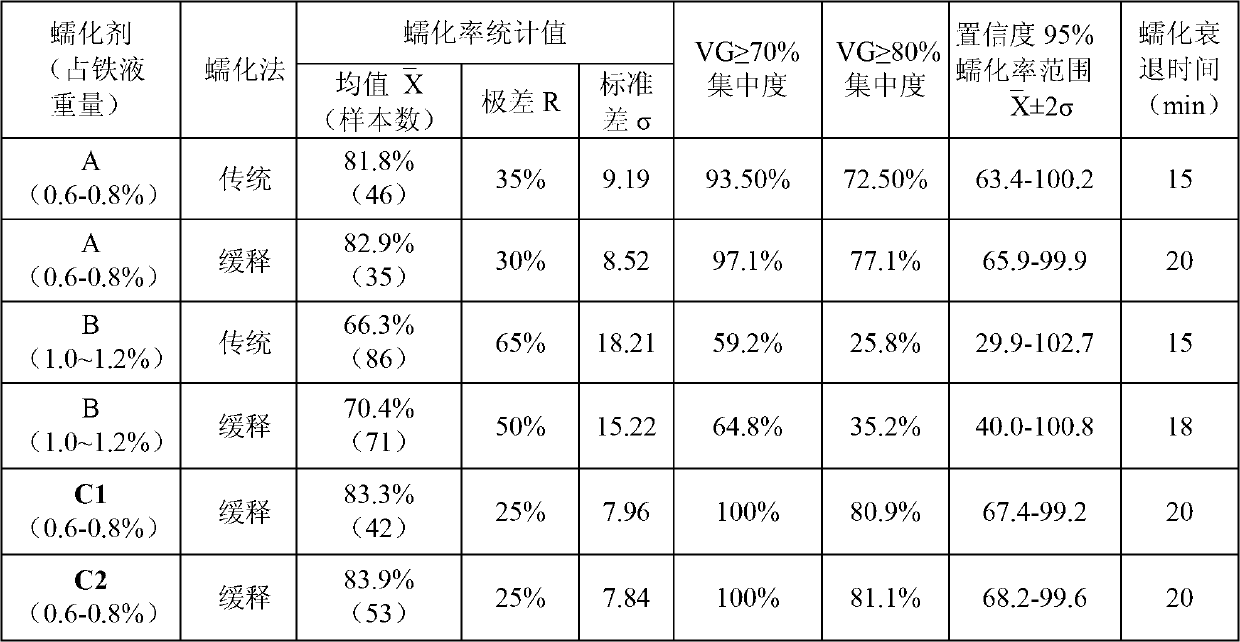

[0004] However, there are two major problems in the existing technology: a) The creep rate range is difficult to control. Under the same production conditions, the creep rate difference (extreme difference) between different treatment packages may reach 50~70%, and the allowable extreme The difference should be ≤30%; b). It is difficult to obtain a high creep rate. Many important creep iron parts such as automobile engine cylinder blocks and cylinder heads require a creep rate of ≥70% or even ≥80%.

At the same time, the decline time of the existing creeping technology is relatively short, resulting in a lot of molten iron that cannot be cast before the decline and can only be returned to the furnace for resmelting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] The content of the present invention will be described in detail below in combination with specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a vermicular cast iron and a manufacturing method of the vermicular cast iron. The manufacturing method comprises steps as follows: preparing furnace burden, melting liquid iron, carrying out vermicularizing treatment and pouring the cast, paving a vermicularizing agent on the bottom of a vermicularizing device and covering a slow-release isolation layer on the vermicularizing layer in a vermicularizing treatment process. The vermicular cast iron prepared by the invention is characterized by small chilling tendency of the vermicular cast iron, small length-thickness ratio of vermicular graphite and good ductility and toughness. With the adoption of the method provided by the invention, the vermicularizing effect of the vermicular cast iron is improved, the range of the vermicularizing rate is decreased, and the vermicularizing declay time is prolonged.

Description

technical field [0001] The invention relates to a vermicular graphite cast iron and a manufacturing method thereof. Background technique [0002] Vermicular graphite cast iron (hereinafter referred to as vermicular iron) is an engineering material that began to be applied in the 1970s, but the development speed in the past 40 years is not as fast as that of ductile iron. One of the important reasons affecting the development of vermicular iron is that the range of creep rate is difficult to control. [0003] Both the ISO standard and the national standard define the creep rate ≥ 80% as vermicular graphite cast iron, but also point out that since the cooling rate has a great influence on the creep rate, it is not always required for each casting that the creep rate is everywhere It is more than 80%, and the best creep rate can be determined according to the structure and actual use of the casting. [0004] However, there are two major problems in the existing technology: a)...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21C1/08C22C33/08C22C37/10B22D1/00

Inventor 徐美珍万仁芳

Owner 福建省南平市建阳区杜氏铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com