Method for operating nozzle

A nozzle and internal combustion engine technology, which is applied in the directions of fuel injection control, engine starting, and engine motor starting, etc., can solve problems such as prolonging the starting time of vehicles, and achieve the effect of reducing the starting time and improving the starting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

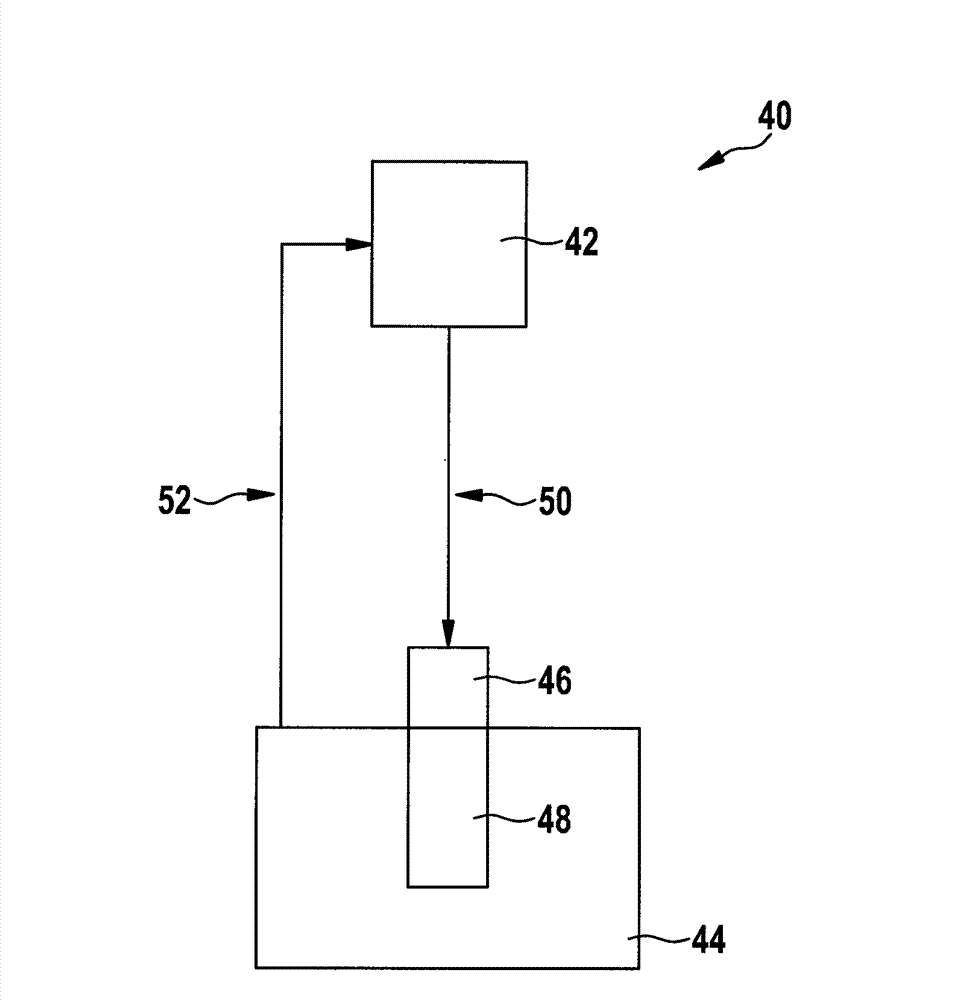

[0022] The invention is shown schematically in the drawing with the aid of an exemplary embodiment and will be described in detail below with reference to the drawing.

[0023] Continuing and comprehensively describing the drawings, like reference numerals refer to like components.

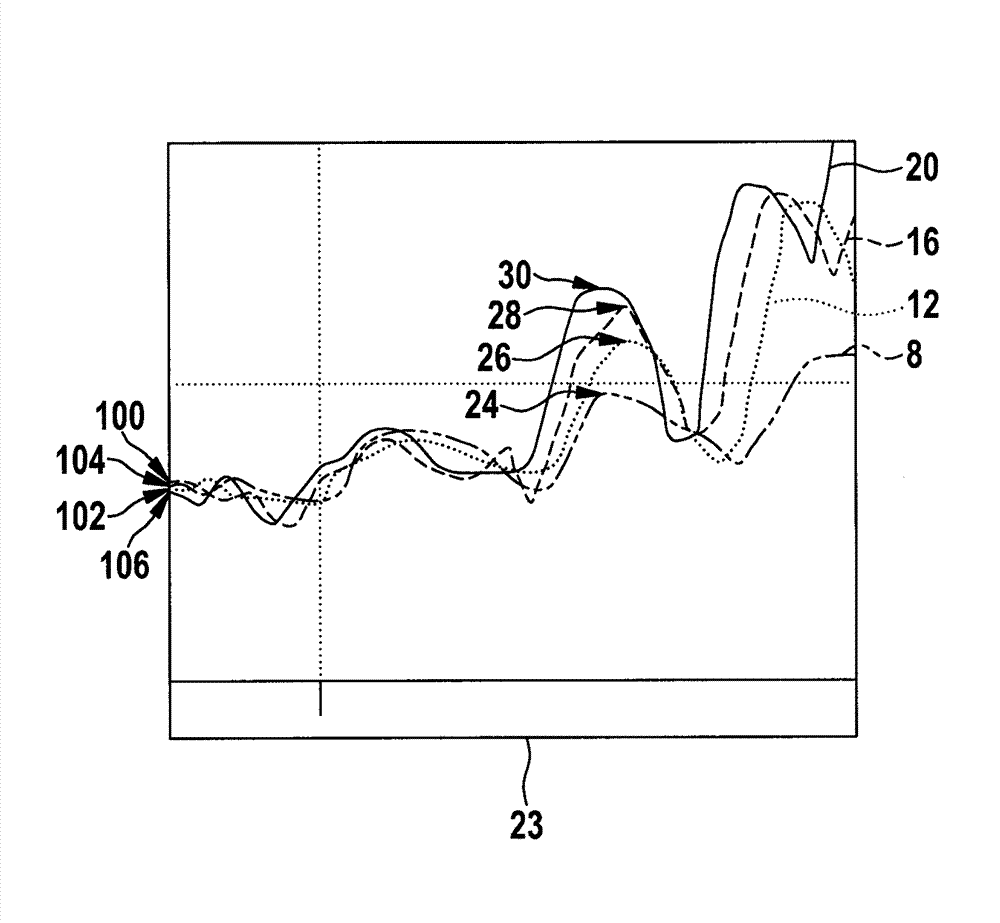

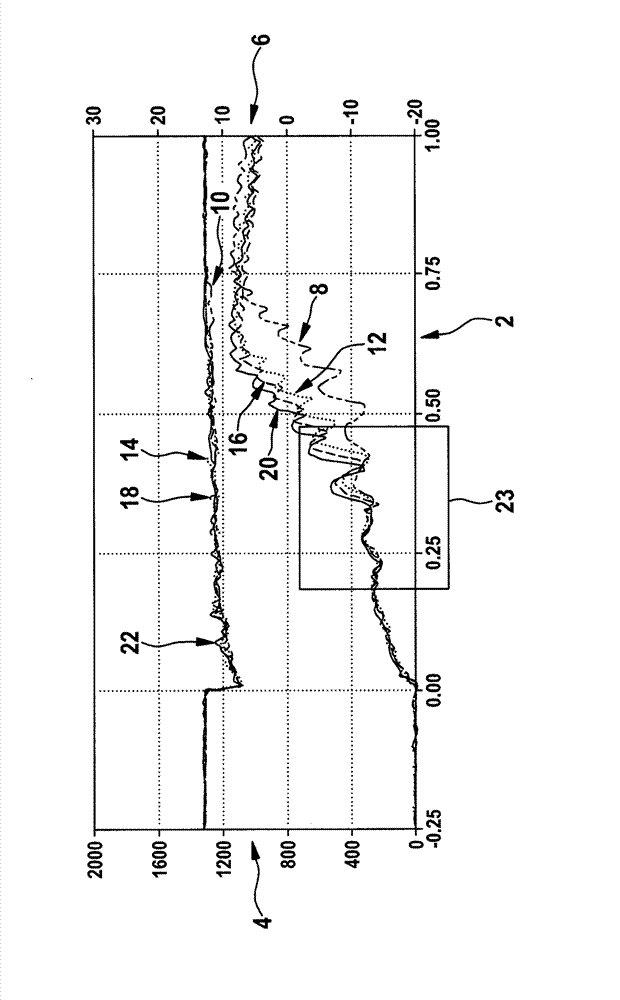

[0024] according to Figure 1a The graph for includes abscissa 2 along which time is recorded in seconds. Along the first ordinate 4 (left), the rotational speed of the internal combustion engine is recorded in revolutions per minute, and along the second ordinate 6 (right), the voltage of the battery of the internal combustion engine is recorded in volts.

[0025] A first curve 8 shows the rotational speed of the internal combustion engine at a fuel quantity injected by the nozzles of 4.3 mg per cylinder stroke, and the resulting cranking time of 636 ms in which the fuel pressure reaches the cranking release pressure. A first voltage curve 10 shows the resulting battery voltage curve. With a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com