Squeeze film damper for transmission shafting

A technology of extruded oil film damping and damper, which is applied in the field of damping and vibration reduction, can solve problems such as inconvenient installation, and achieve the effects of convenient manufacturing and installation, simple structure, and good damping and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

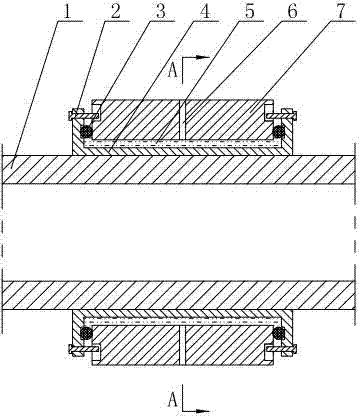

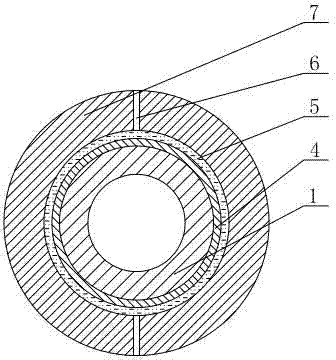

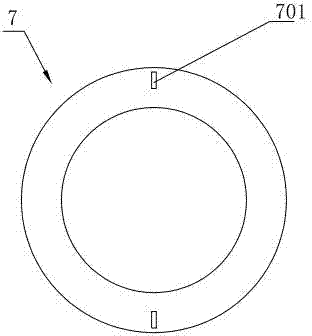

[0021] Such as figure 1 with figure 2 As shown, the transmission shaft system extrusion oil film damper of this embodiment is used to reduce the lateral vibration of the shaft system. The outer ring 7 of the damper is arranged in the circumferential groove of the inner ring 4 of the damper, and an oil chamber is formed between the outer ring 7 of the damper and the inner ring 4 of the damper, and lubricating oil 5 is placed in the oil chamber to play a damping role. The two ends of the cavity are sealed by the sealing ring 3, and the groove openings of the damper inner ring 4 are respectively connected with the two ends of the damper outer ring 7 through connecting pieces. See image 3 , the outer surfaces of both ends of the damper outer ring 7 are respectively provided with axisymmetric rectangular grooves 701, and the middle part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com