Fiber bragg grating based composite material thermal expansion coefficient measuring device and measuring method

A technology of thermal expansion coefficient and fiber grating, applied in the field of measurement, can solve the problems that fiber grating cannot be reused, cannot meet higher precision requirements, and low resolution cannot meet requirements, etc., achieve high precision requirements, improve measurement sensitivity, and work reliably good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

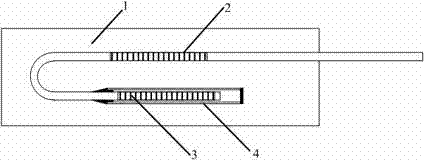

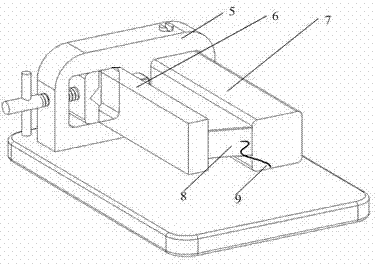

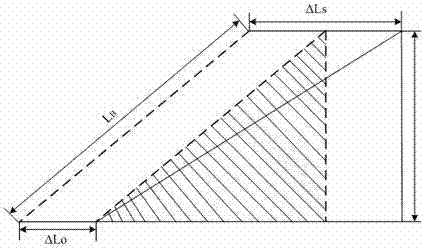

[0021] The measurement means and method are realized through the following technical solutions: a fiber grating-based thermal expansion coefficient test experimental device, including a standard sample block with a known thermal expansion coefficient, whose CTE is greater than the estimated value of the composite material; fixed standard sample block And the fixture of the composite material block to be tested has the function of adjusting the clamping position; the fiber grating sensor of the strain-intensified package, the fiber grating demodulator, and the temperature control box.

[0022] The composite material block to be tested and the standard sample block are fixed on the fixture in parallel, the distance between the composite material and the standard sample block is fixed, and the length of the free end of the test piece is greater than that of the composite material. One end of the encapsulated grating sensor is fixed on the free end of the standard sample block, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com