Universal power semiconductor module fixture

A technology for power semiconductors and fixtures, which is used in the testing of single semiconductor devices, measuring device casings, etc., can solve problems such as poor versatility, achieve accurate thermal resistance test results, improve versatility and ease of use, and prevent horizontal movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

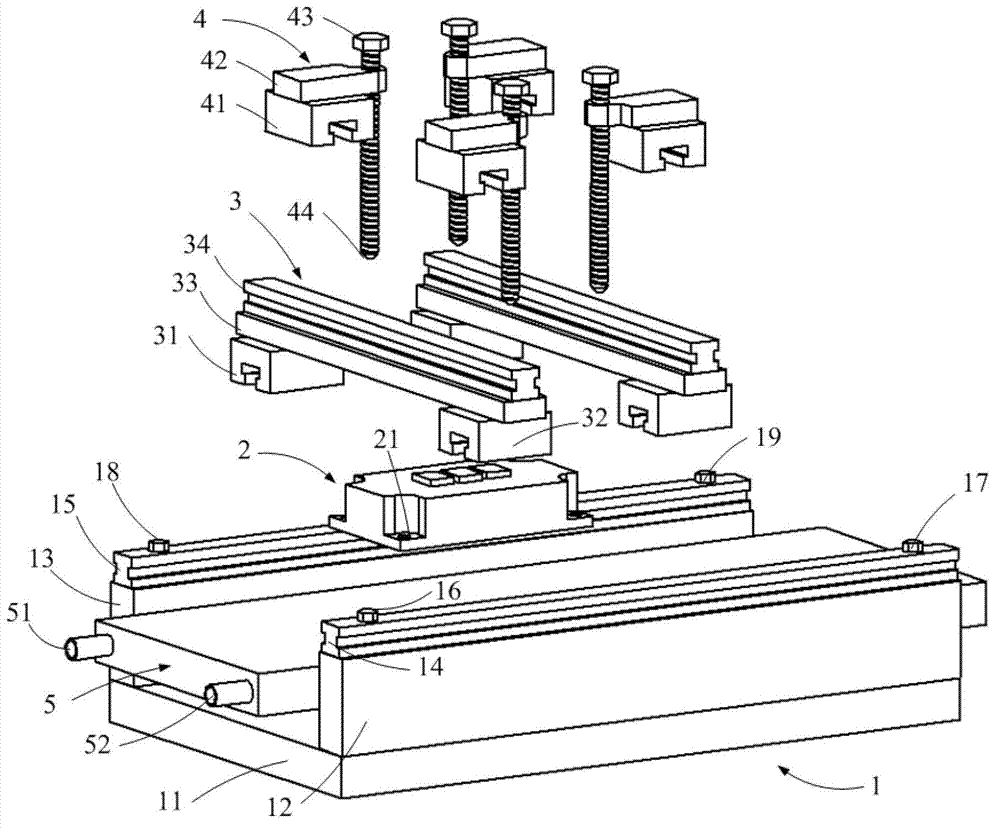

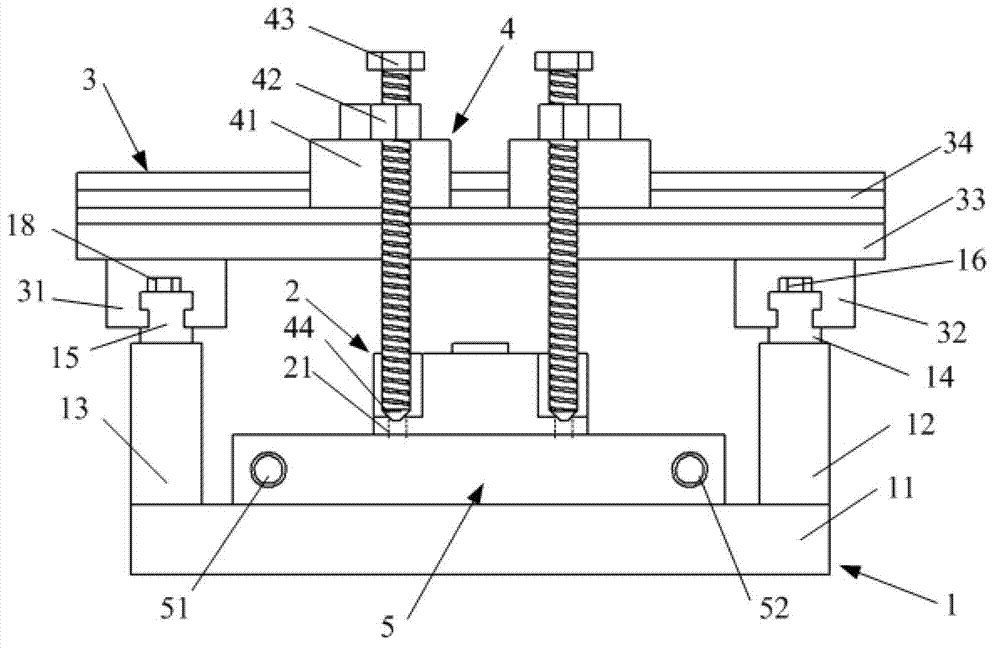

[0031] This embodiment is suitable for testing using an independent liquid cold plate.

[0032] like figure 2 As shown, the liquid cooling plate 5 is placed on the bottom plate 11 , and the bottom surface of the power semiconductor module 2 to be tested is coated with thermal conductive silicone grease, and placed on the liquid cooling plate 5 . Slide the position of the slide rail group 3, and then adjust the position of the slider group 4 to ensure that the fastening bolt 43 is perpendicular to the mounting hole 21 of the power semiconductor module 2 to be tested. Turn the fastening bolt 43 so that the fastening bolt 43 moves downward perpendicular to the power semiconductor module 2 to be tested, and the tapered end 44 of the fastening bolt 43 enters the mounting hole 21 of the semiconductor power module 2 to be tested. Design, its maximum diameter is larger than the diameter of the installation hole 21, and the minimum diameter is smaller than the diameter of the install...

Embodiment 2

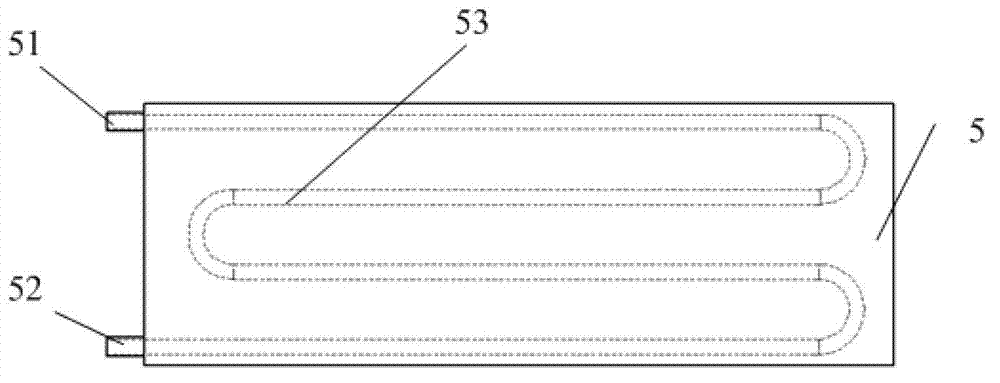

[0036] This embodiment is applicable to a test in which a liquid channel is directly integrated on the bottom plate of the fixture without using an independent liquid cooling plate.

[0037] like Figure 4As shown, the power semiconductor module 2 under test whose bottom surface is coated with thermal conductive silicone grease is placed on the bottom plate 110 integrated with the liquid channel. Slide the position of the slide rail group 3, and then adjust the position of the slider group 4 to ensure that the fastening bolt 43 is perpendicular to the mounting hole 21 of the power semiconductor module 2 to be tested. Turn the fastening bolt 43 so that the fastening bolt 43 moves downward perpendicular to the power semiconductor module 2 to be tested, and the tapered end 44 of the fastening bolt 43 enters the mounting hole 21 of the semiconductor power module 2 to be tested. design, its maximum diameter is larger than the aperture of the mounting hole 21, and its minimum diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com