Aspherical focal length-variable photoetching objective lens system

A technology of lithography objective lens and variable focal length, which is applied in the field of optics, can solve the problem that the same lithography objective lens cannot be used to expose different proportions of mask template exposure patterns, etc., and achieve optical total length, compact structure, and small aperture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

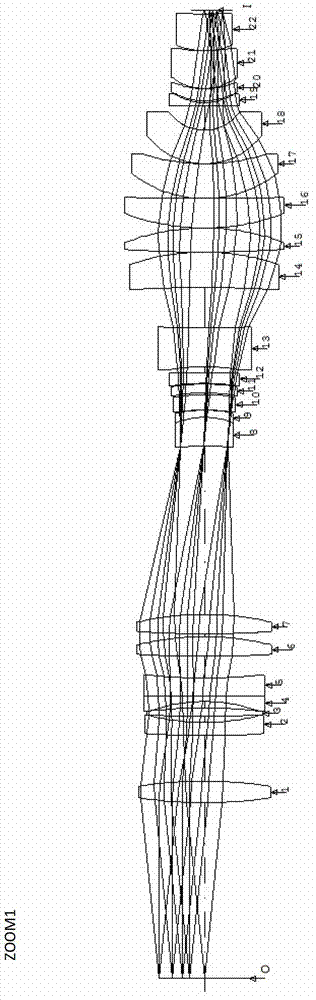

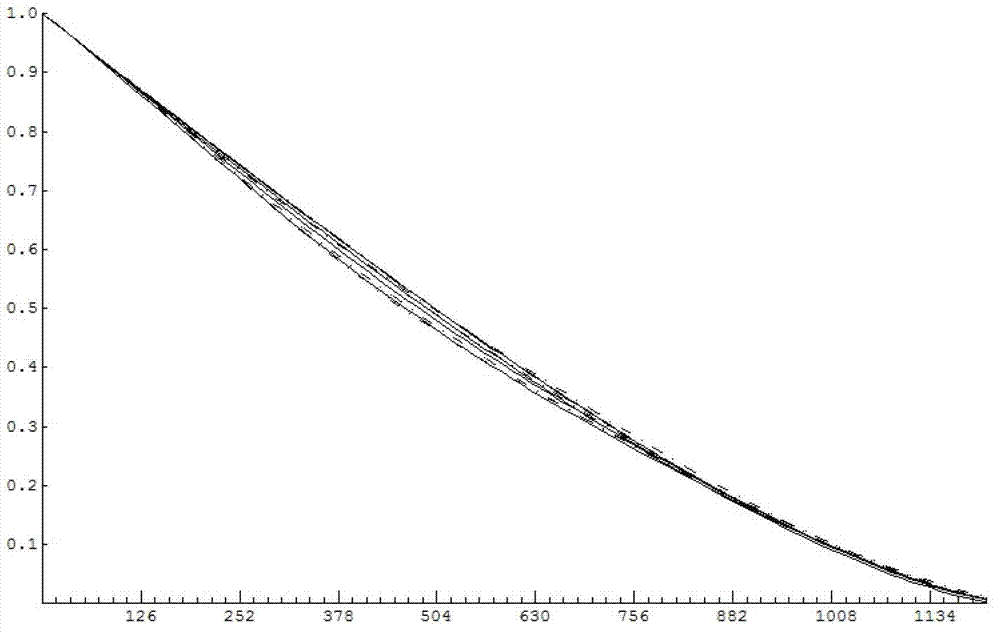

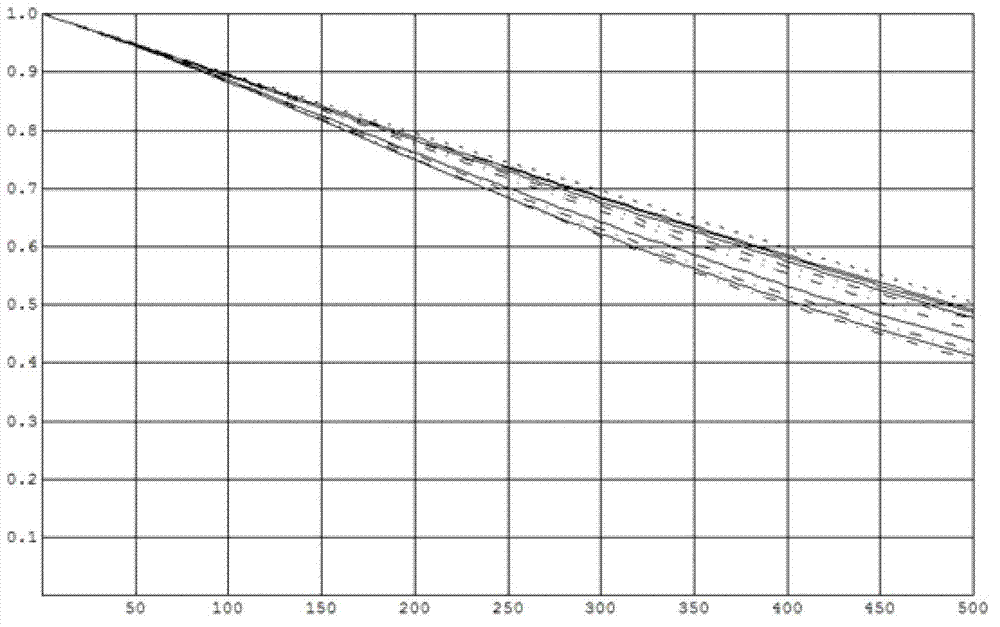

[0041] Embodiment 1: as figure 1 As shown, the present invention provides a kind of refraction type aspherical variable focal length lithography objective lens system working at a wavelength of 410nm by the structure of zoom1, which is used to image the pattern of the object plane O on the image plane I, which consists of 22 optical lenses Composition, the lens is marked as L1~L22 from the object side to the image side, the 22 optical lenses are divided into G1~G5 groups according to the power and the role in the system of the present invention, the distribution of power from the object plane The order to the image plane is positive-negative-positive-negative-positive, the distance from the object plane to the image plane is 805mm, the largest lens in the system has a full aperture of less than 153mm, the image square F number is 2, the image square numerical aperture is 0.2, and the magnification is 0.25. The image size is 14.8mm.

[0042] The specific structure of the asphe...

Embodiment 2

[0062] Such as Figure 6 As shown, the structure diagram of the present invention at the zoom position zoom2, such as Figure 7 As shown, the transfer function graph of the optical system at the zoom position zoom2, such as Figure 8 As shown, the transfer function graph of the present invention when zoom position zoom2 is 1 μm away from focus, such as Figure 9 and Figure 10 As shown, the present invention has field curvature and distortion graphics at the zoom position zoom2.

Embodiment 3

[0064] Such as Figure 11 As shown, the structure diagram of the present invention at the zoom position zoom3, such as Figure 12 As shown, the transfer function graph of this optical system, such as Figure 13 As shown, the transfer function graph of the present invention when the zoom position zoom3 is defocused by 1 μm, such as Figure 14 and Figure 15 As shown, the field curvature and distortion graph of the present invention at the zoom position zoom3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com