Lithium-iron disulfide battery

An iron disulfide battery, lithium salt technology, applied in lithium batteries, secondary batteries, battery pack components, etc., can solve the problems of destroying consumer trust, burning danger, personal and property safety threats, and complexity, and achieve excellent safety. performance, good discharge performance, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

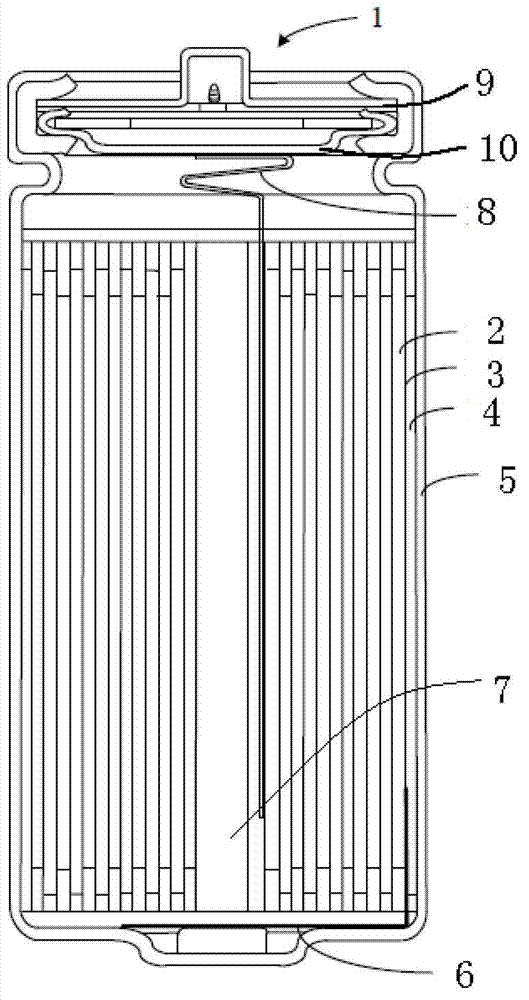

Image

Examples

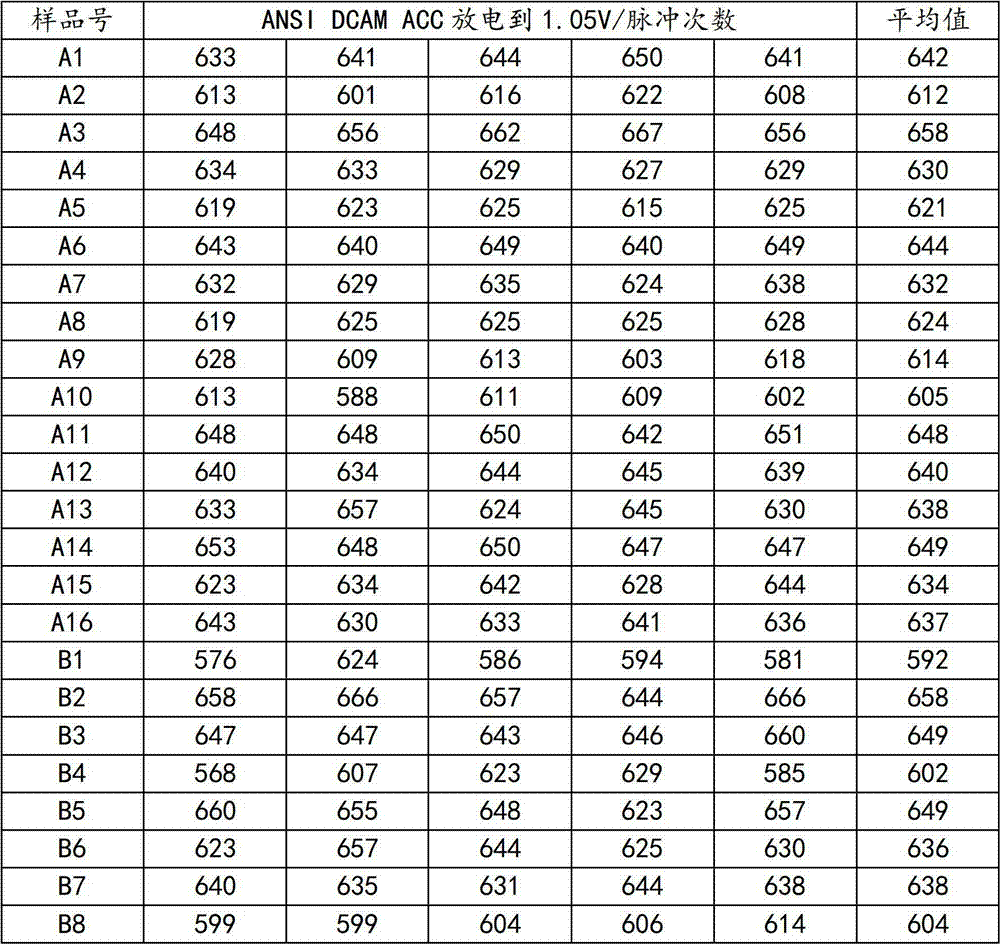

Embodiment 1

[0068] The electrolyte solution is prepared as follows: 490ml of anhydrous 1,2-dimethoxyethane and 490ml of anhydrous 1,3-dioxolane are mixed according to the volume ratio equal to 1. The above solvents can be obtained from Suzhou Nolight Co., Ltd. get. γ-butyrolactone and anhydrous lithium iodide (LiI) were both from Zhangjiagang Guotai Huarong Co., Ltd. Take the above mixed solvent and 20ml of γ-butyrolactone and mix them evenly in a container with a volume of 2000ml, then gradually add anhydrous lithium iodide into it, stir to make it fully dissolve, and obtain an electrolyte with a conductivity of 7.5mS / cm . The process of preparing the above electrolytes is carried out in a dry room with a dew point of -40°C.

[0069] The prepared electrolyte was used as the electrolyte, and a polyethylene microporous membrane with a thickness of 20 microns (model COD-120, produced by Asahi Kasei Co., Ltd., with a closed cell temperature of 145°C) was used as a separator, and was produc...

Embodiment 2

[0071] The method is the same as in Example 1, except that the addition of anhydrous lithium iodide is changed to prepare an electrolytic solution with a conductivity of 6.5mS / cm, and the AA-type lithium-iron disulfide battery is made with this electrolytic solution. for A2.

Embodiment 3

[0073] The method is the same as in Example 1, except that the addition of anhydrous lithium iodide is changed to prepare an electrolytic solution with a conductivity of 8.0mS / cm, and the AA-type lithium-iron disulfide battery is made with this electrolytic solution. for A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com