Motor rotor bearing assembly machine

A technology for motor rotors and assembling machines, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of unstable product quality, high labor intensity, and high processing costs, reducing labor usage and labor intensity. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

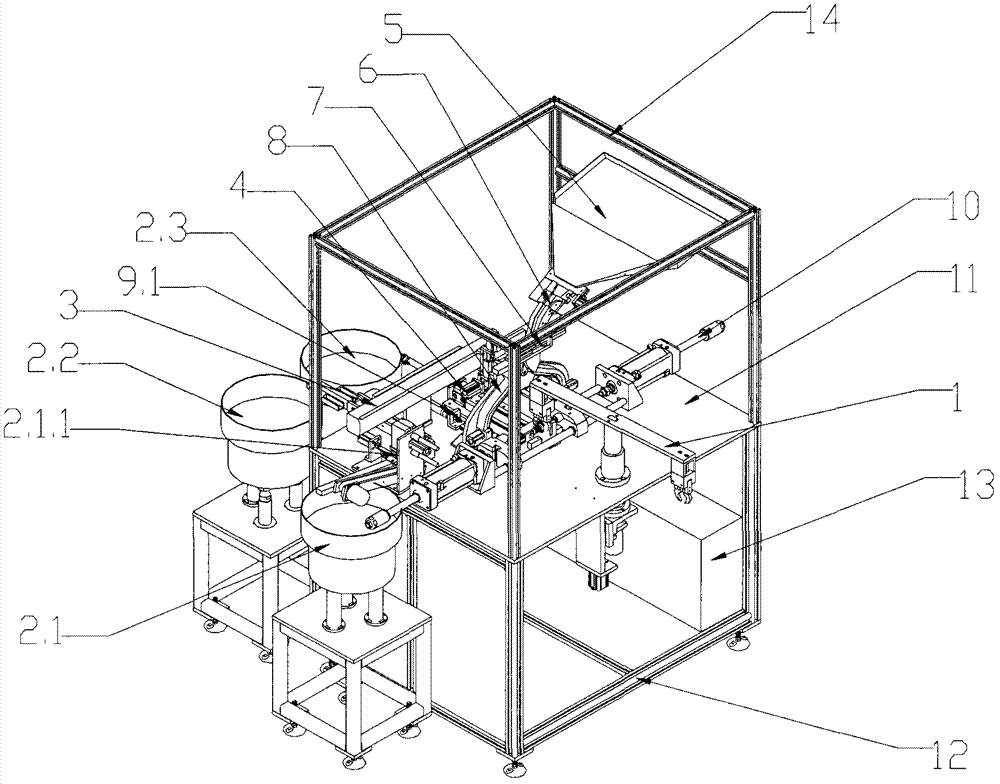

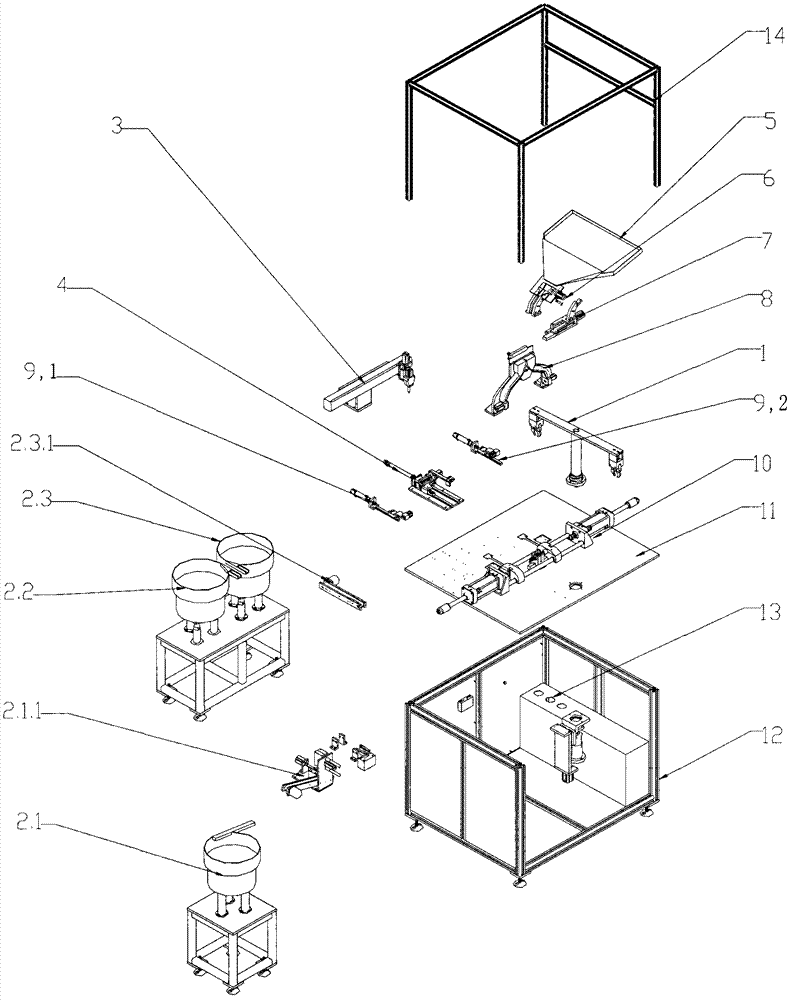

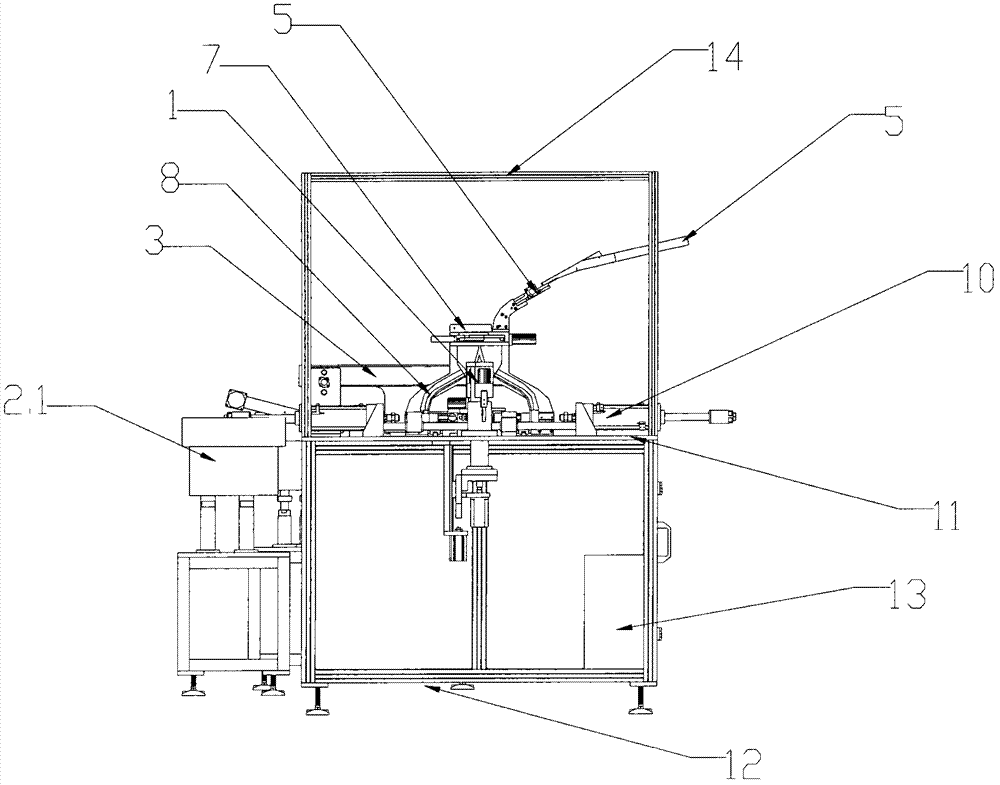

[0026] Examples, see Figure 1 to Figure 5 Shown:

[0027] A motor rotor bearing assembly machine, comprising a machine base 12 and an electrical box 13 located inside the machine base 12, a frame 14 located above the work table 12, and a work table located above the machine base 12 11. The motor rotor feeding / retrieving manipulator 1, the bearing assembly mechanism 10, the bearing left feeding mechanism 9.1 and the bearing right feeding mechanism 9.2 are arranged on the working table 11 from front to back, and are arranged on the working table from bottom to top. Bearing left and right material distribution mechanism 8 above the bearing feeding mechanism, bearing positive and negative identification and adjustment mechanism 7, bearing feeding anti-jamming mechanism 6 and bearing feeding placement plate 5 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com