Process and device for distilling polymerization-prone compounds

A distillation equipment and an easy-to-polymerize technology, which is applied in the field of distillation treatment, can solve the problems of reducing the available working volume of rectification, reducing the production capacity of distillation tower, and the linear evaporation speed can not be achieved, so as to reduce undesired side reactions, reduce size, improve The effect of heat exchange

Active Publication Date: 2012-11-21

LURGI

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when applying this teaching, problems arise, especially during start and stop operations, since the then required linear evaporation rate cannot or can no longer be maintained

Furthermore, the integral formation of the evaporator and condenser further reduces the available working volume for rectification and thus reduces the production capacity of the distillation column

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

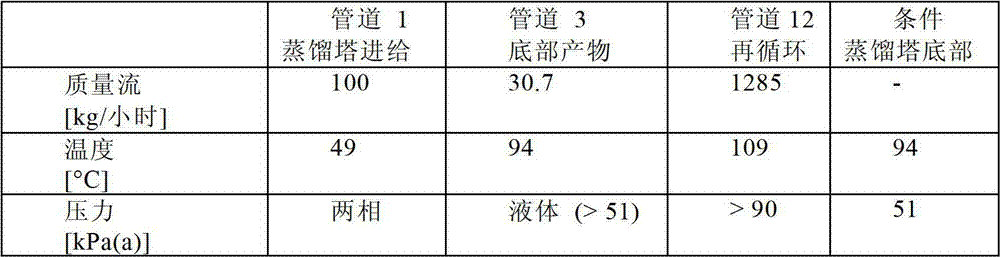

[0055]Example 1: Separation of lower boiling components (solvent / water) as top product. The bottom product consists mainly of acrylic acid.

[0056]

[0057] Example 2: Separation of pure acrylic acid as top product. In addition to acrylic acid, the bottoms product also contains impurities and oligomers in the form of inhibitors.

[0058]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

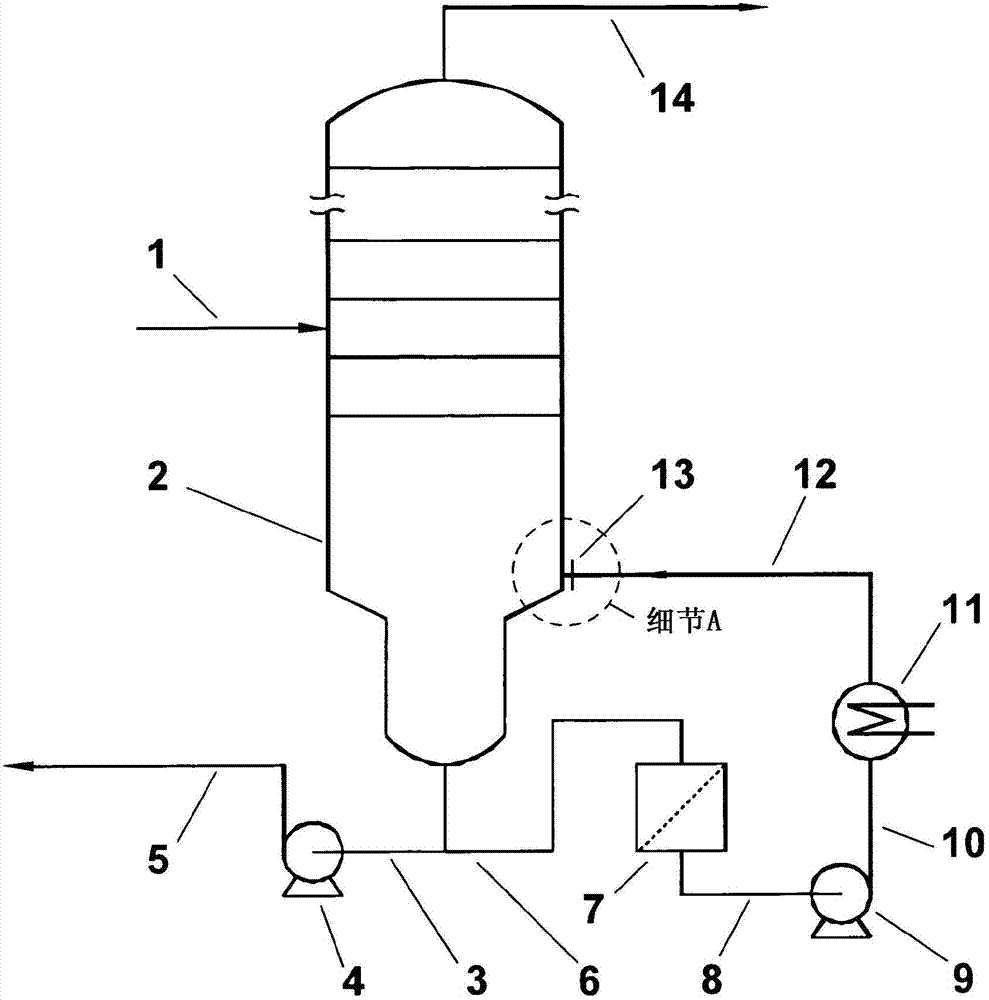

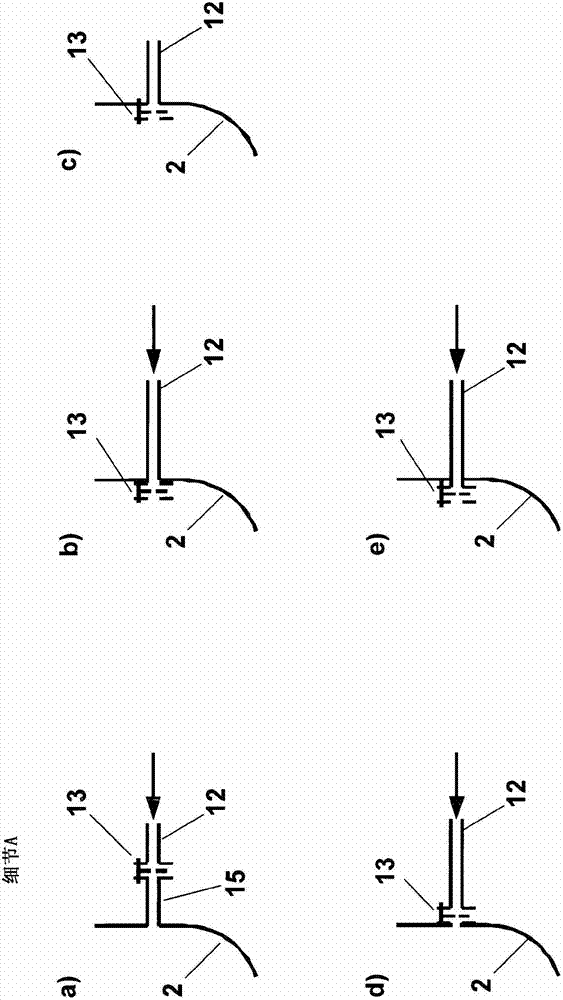

In a process for distilling polymerization-prone compounds from liquid mixtures of matter which, apart from the readily polymerizable compound, also contain other components and also polymerization inhibitors, the evaporator is operated in forced circulation and at a pressure which makes possible superheating of the liquid with respect to its boiling point at the pressure within the distillation column. This is achieved by transporting the superheated liquid against a flow restrictor, e.g. an orifice plate. The liquid which is expanded and partially evaporated on passage through the flow restrictor is returned to the distillation column. In this manner the formation of an open vapour space in the evaporator circuit after heating downstream of the heat exchanger is avoided in that, in the design of the evaporator of the prior art, formation of polymer deposits frequently occurs.

Description

technical field [0001] The present invention relates to a process for the distillation treatment of mixtures of substances comprising readily polymerizable compounds. In particular, the invention relates to the distillation purification of acrylic acid or methacrylic acid. The invention also relates to equipment for carrying out the process according to the invention. Background technique [0002] Acrylic acid and its esters are increasingly used throughout the world and mainly in the production of polymers. As explained in Ullmann's Encyclopedia of Industrial Chemistry (Sixth Edition, electronic distribution 1998), under the key words "acrylic acid and esters", most commercially used acrylic acid is produced by Produced by the selective oxidation of propylene, it also represents the starting material for acrolein. The selective oxidation of propylene is carried out in the gas phase as a heterogeneously catalyzed reaction using air as oxidant. The acrylic acid is first s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D3/32C07C51/44

CPCC07C51/50C07C51/44B01D3/322C07C57/04B01D3/00

Inventor 弗兰克·卡斯提罗维尔特尔克劳斯·基尔斯滕约亨·鲍尔克里斯托弗·斯特丹多米尼克·瓦尔塔马库斯·克赖鲁多夫·策恩

Owner LURGI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com