Electromagnetic-shielding film, flexible substrate formed using same, and process for producing same

A flexible substrate, electromagnetic wave technology, applied in the direction of magnetic/electric field shielding, crosstalk/noise/electromagnetic interference reduction (, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of not obtaining electromagnetic wave shielding film, etc., to achieve The effect of excellent electromagnetic wave shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Examples of the present invention are shown below, but the present invention is not limited to the following examples.

[0044] [Example, comparative example]

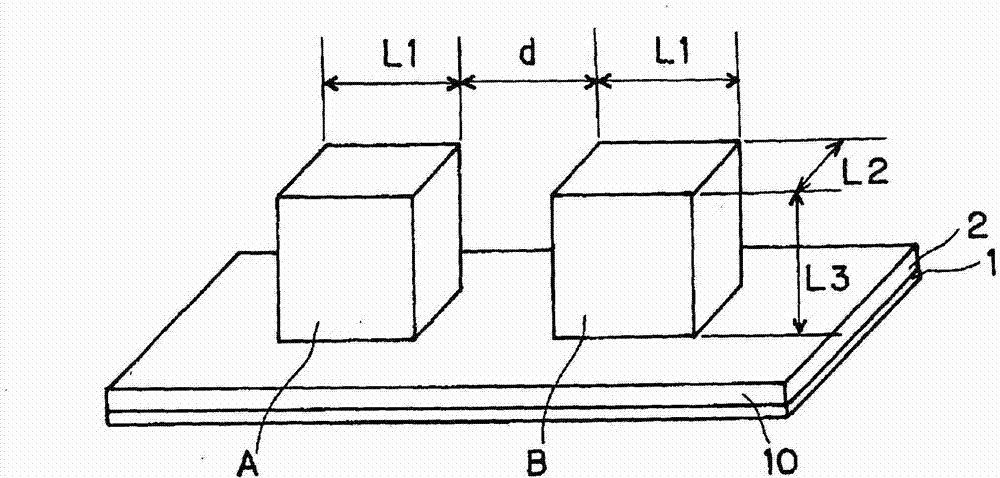

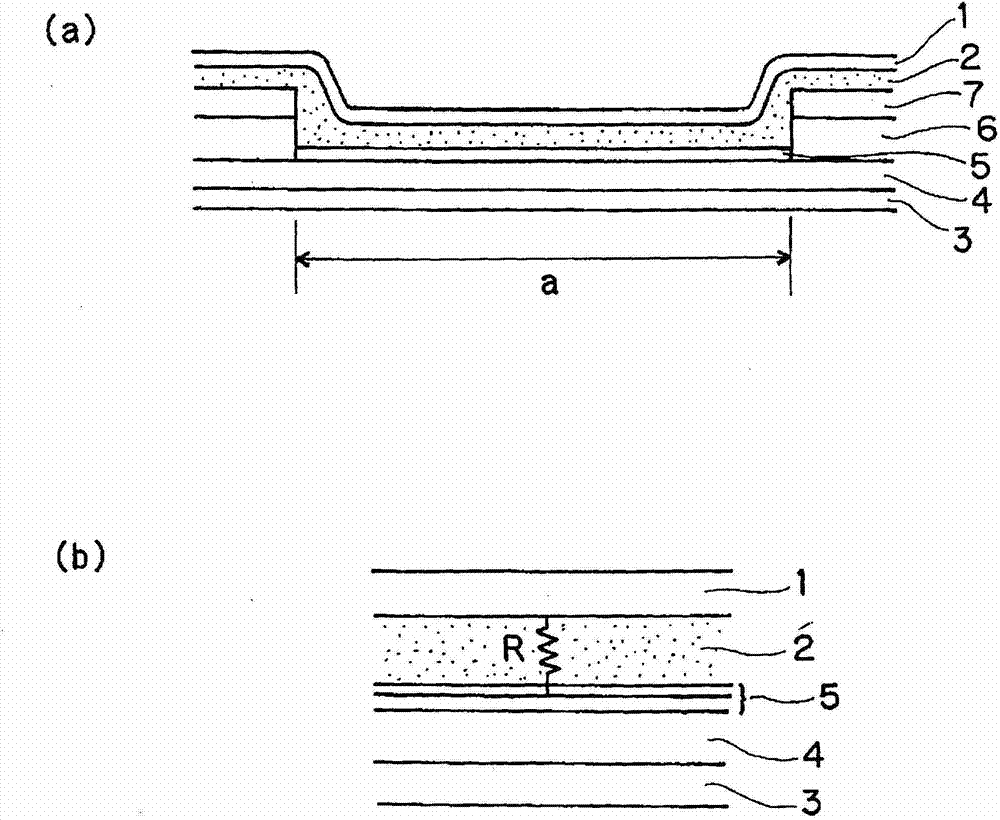

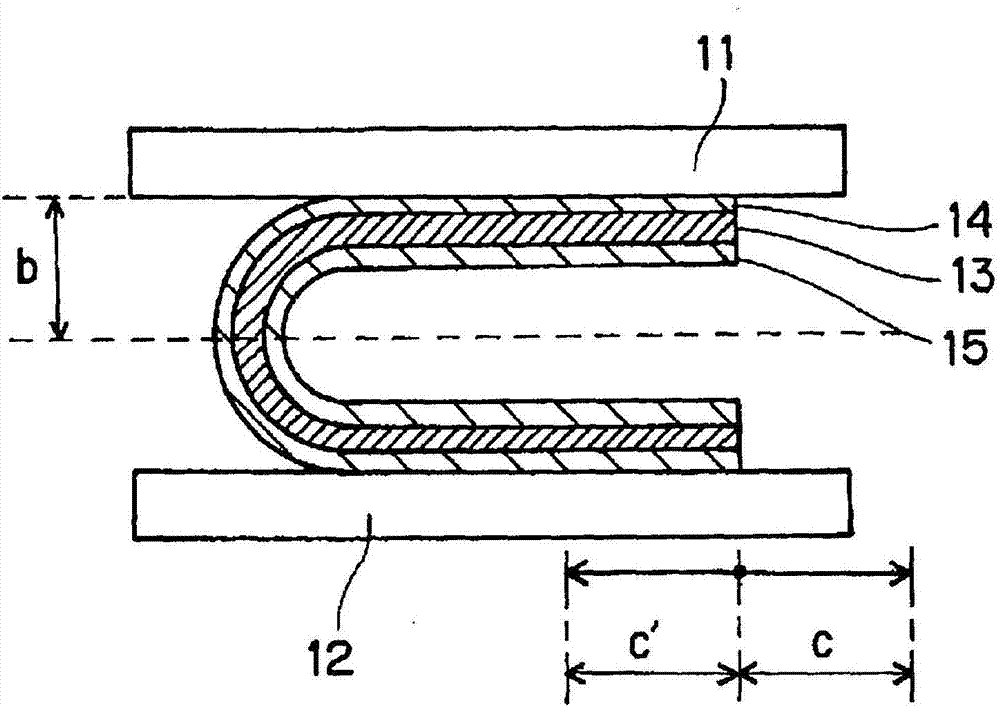

[0045] A two-layer structure consisting of an epoxy-based soft layer and an acrylic hard-coat layer is formed by applying and drying an epoxy-based resin to a thickness of 6 μm on a release film, and applying and drying an acrylic hard-coat liquid on top of it. protective layer (described later figure 1 , 2 symbol in 1). On this protective layer, coat the conductive paste formulated by the proportion shown in table 1, 2, and form a conductive layer by drying (the same figure 1 , 2 Symbol 2 in ) to obtain an electromagnetic wave shielding film. The following evaluations were performed using the obtained electromagnetic wave shielding film. Details of the binder resin and metal powder used are as follows.

[0046] Binder resin: Dainichi Seika Co., Ltd., polyurethane resin UD1357

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com