Zinc-plated plastic-lined composite pipe production technology and composite pipe

A production process and composite pipe technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve problems such as complex process flow, and achieve the effect of simple production process operation, high production efficiency, and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

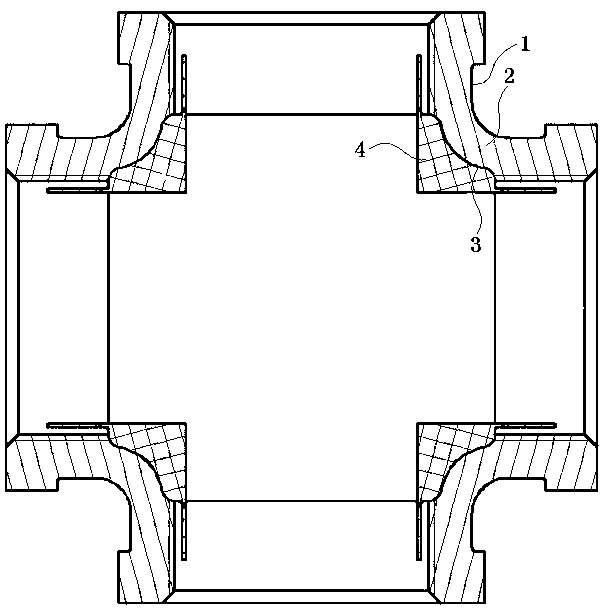

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0017] The production process of an outer galvanized composite pipe lined with plastic according to the present invention sequentially performs the following treatments on the galvanized pipe fittings:

[0018] 1. Degreasing: Use 100% degreasing oil or white electric oil to clean the surface of galvanized pipe fittings, sometimes with the help of an ultrasonic cleaner.

[0019] 2. Anti-rust: Use anti-rust liquid to prevent the overall rust of the cleaned galvanized pipes, including the port teeth.

[0020] 3. Glue: Apply a layer of glue to the inner wall of the galvanized pipe fittings except for the tooth pattern.

[0021] 4. Braces installation: Select the corresponding braces according to the specifications of the pipe fittings, and the tooth patterns on the workpiece must be fully protected. The braces must be screwed in place and the silk teeth must n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com