Dye transfer and baking steamed fixation integrated transfer printing

A technology of transfer printing and dyes, applied in the field of textile printing and dyeing industry, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

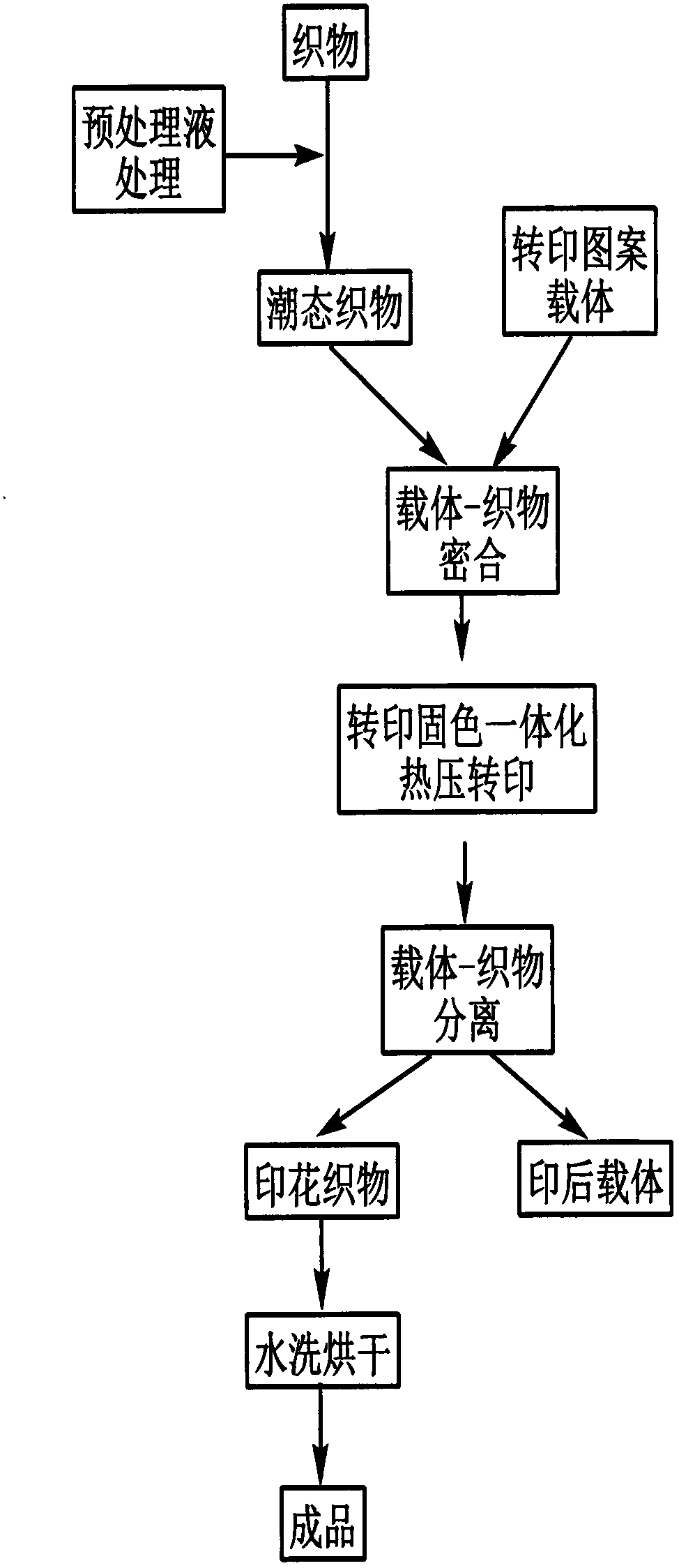

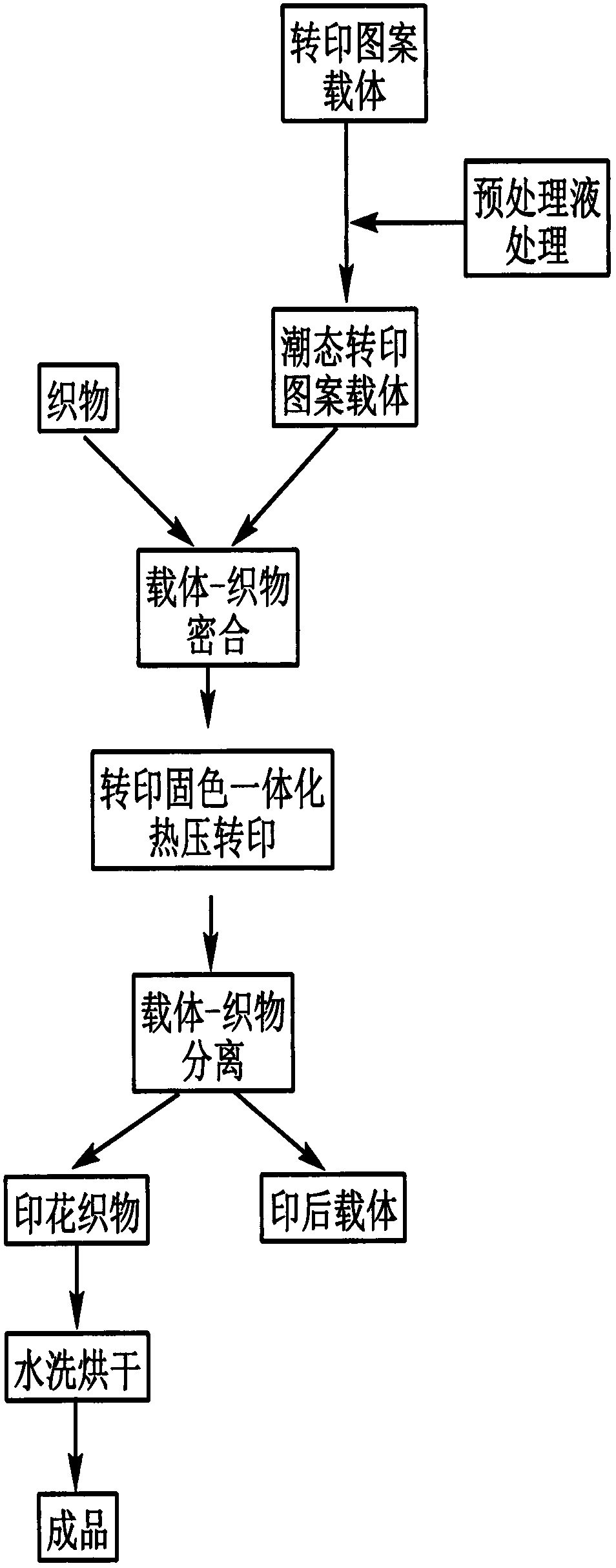

Method used

Image

Examples

Embodiment 1

[0022] Fabric: cotton knitted fabric, 100% cotton, size: 16×16, weight: 185g / m 2 .

[0023] Reactive dyes: K-type (reactive yellow K-RN, reactive red K-7B, reactive turquoise K-GL, reactive black K-BR) pretreatment and its device: foam coating pretreatment and its device, for transfer printing paper Moisture pretreatment.

[0024] Containing (pretreatment liquid) moisture content: 15%.

[0025] Integration of transfer and baking and fixing: platen transfer device and platen heating mechanism. For the baking and color fixing of the platen type transfer device and the platen heating mechanism, see Figure 5 As shown, its transfer device is made of upper platen 7 and lower platen 8 and the pressurization system elevating rod connected therewith, and the inner cavity of the upper and lower platens is equipped with electric heating wire or electric heating tube heating element. When the transfer printing fabric 12 and the transfer printing paper 11 pass through the roller trans...

Embodiment 2

[0030] Fabric: silk fabric, 12107 silk crepe de chine, 91×55, weight: 55g / m 2 .

[0031] Reactive dyes: KN type (reactive orange KN-5R, reactive red KN-3B, reactive brilliant blue KN-R, reactive black KN-B).

[0032] Pretreatment method and its device: padding pretreatment and its device, wet pretreatment of fabrics.

[0033] Containing (pretreatment liquid) moisture content: 65%

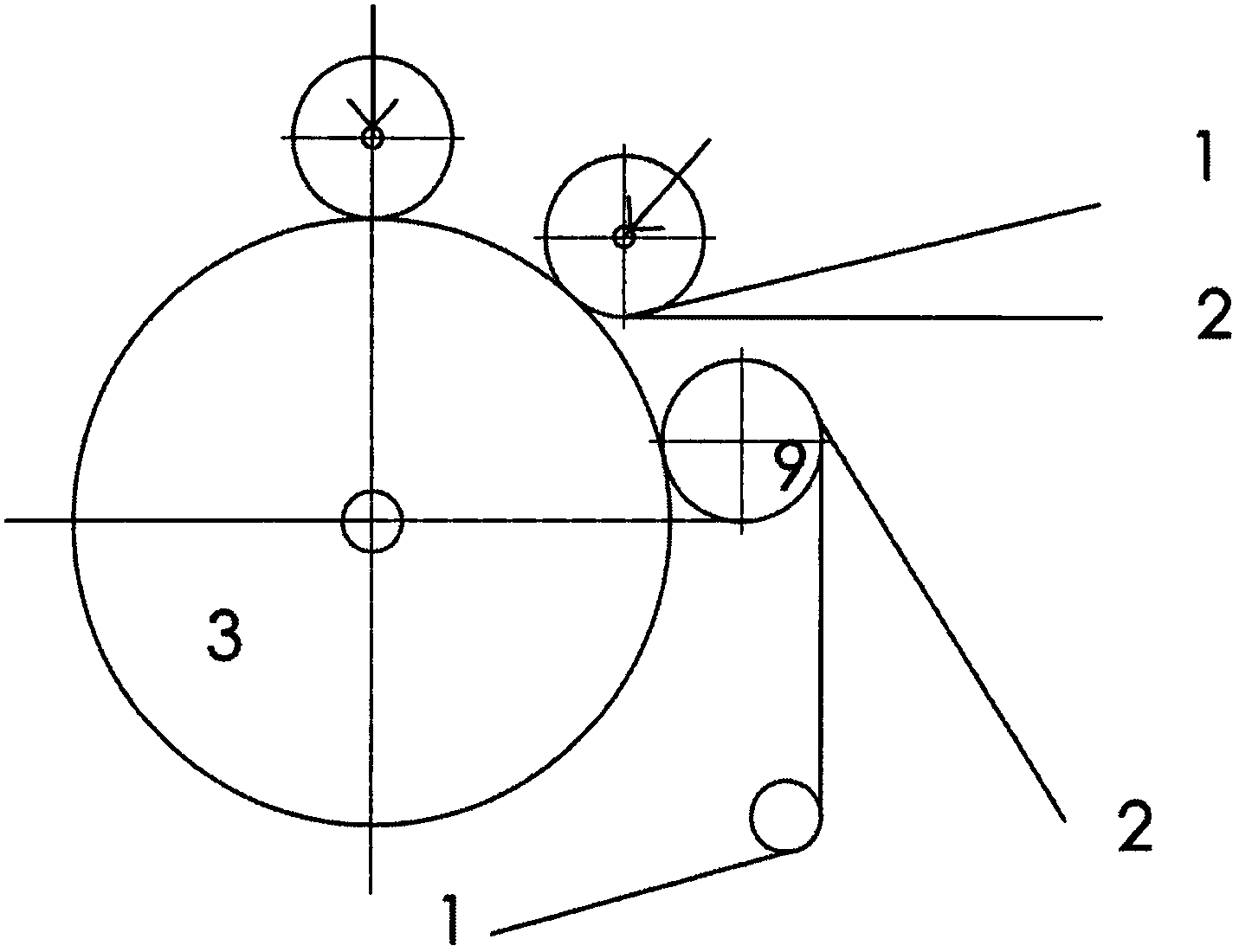

[0034] Integration of transfer and baking color fixation: blanket belt transfer device and main roller heating mechanism. For the baking and color fixing of the blanket belt transfer device and the main roller heating mechanism, see Figure 4 As shown, the transfer device consists of a blanket belt surrounding the main roller 6 and pressure rollers 9 and 10, and the inner cavity of the main roller 6 is equipped with electric heating tube heating elements and heating oil. When the transfer printing fabric 4 and the transfer printing plastic film 5 pass through the roller transfer printing device ...

Embodiment 3

[0038] Fabric: Rayon Knit, 95% Rayon / 5% Spandex, Weight: 150g / m 2 .

[0039] Reactive dyes: ME type (reactive yellow ME-4GL, reactive red ME-2G, reactive brilliant blue ME-BR, reactive black MegafixBES).

[0040] Pretreatment method and its device: foam coating pretreatment and its device, wet pretreatment of transfer printing paper.

[0041] Containing (pretreatment liquid) moisture content: 10%.

[0042] Integration of transfer and baking color fixation: platen transfer device and platen heating mechanism, see Example 1 and Figure 5 . See Table 3:

[0043] table 3

[0044] Fixing temperature(℃)

[0045] Transfer fixation time (s)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com