Minimum over-burden originating method for shield tunnel

A technology of shield tunnel and shallow overburden, which is applied to the origin of shield tunnel with shallow overburden, can solve problems such as formation stability, and achieve the effects of reducing project cost, reducing construction risk, and improving social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

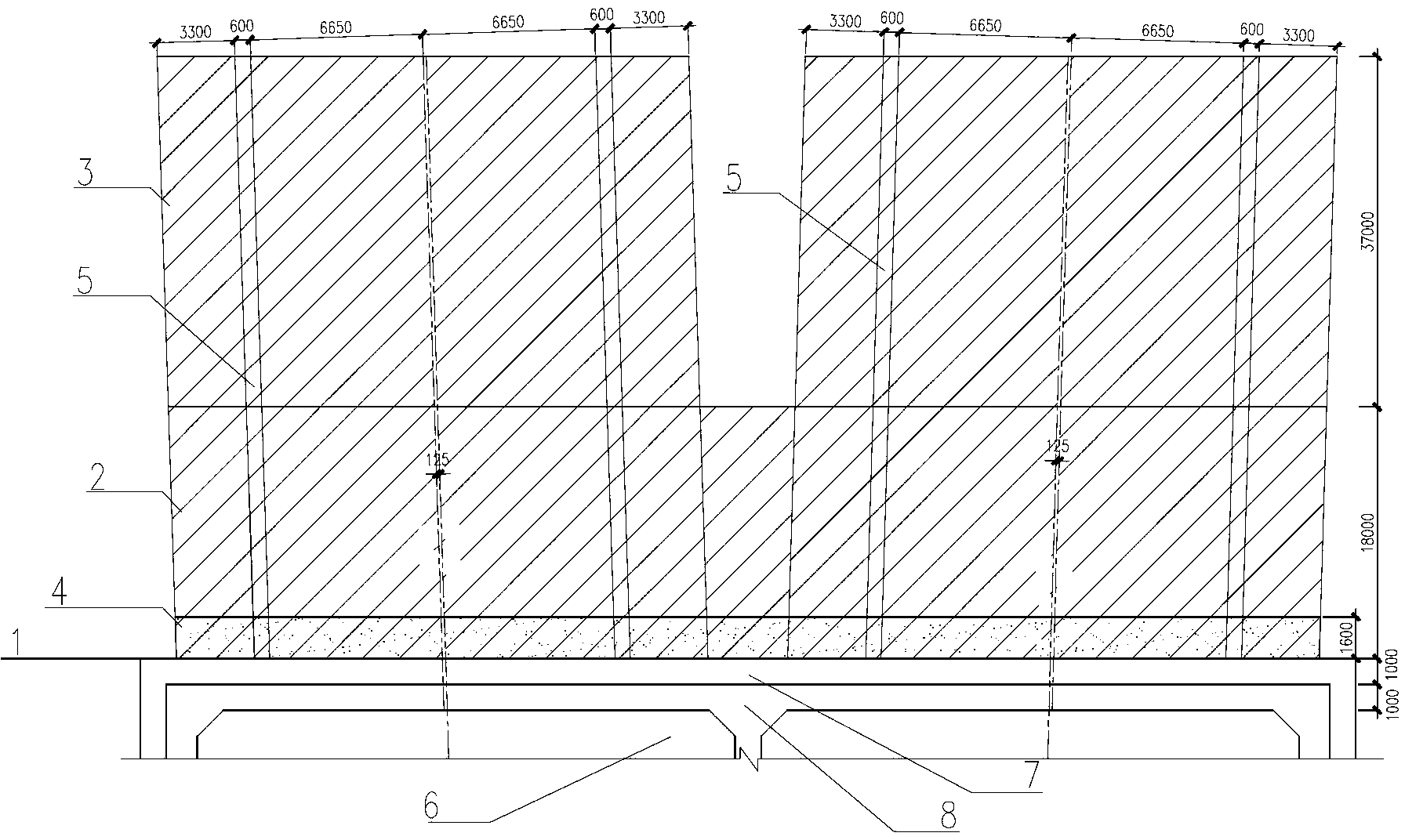

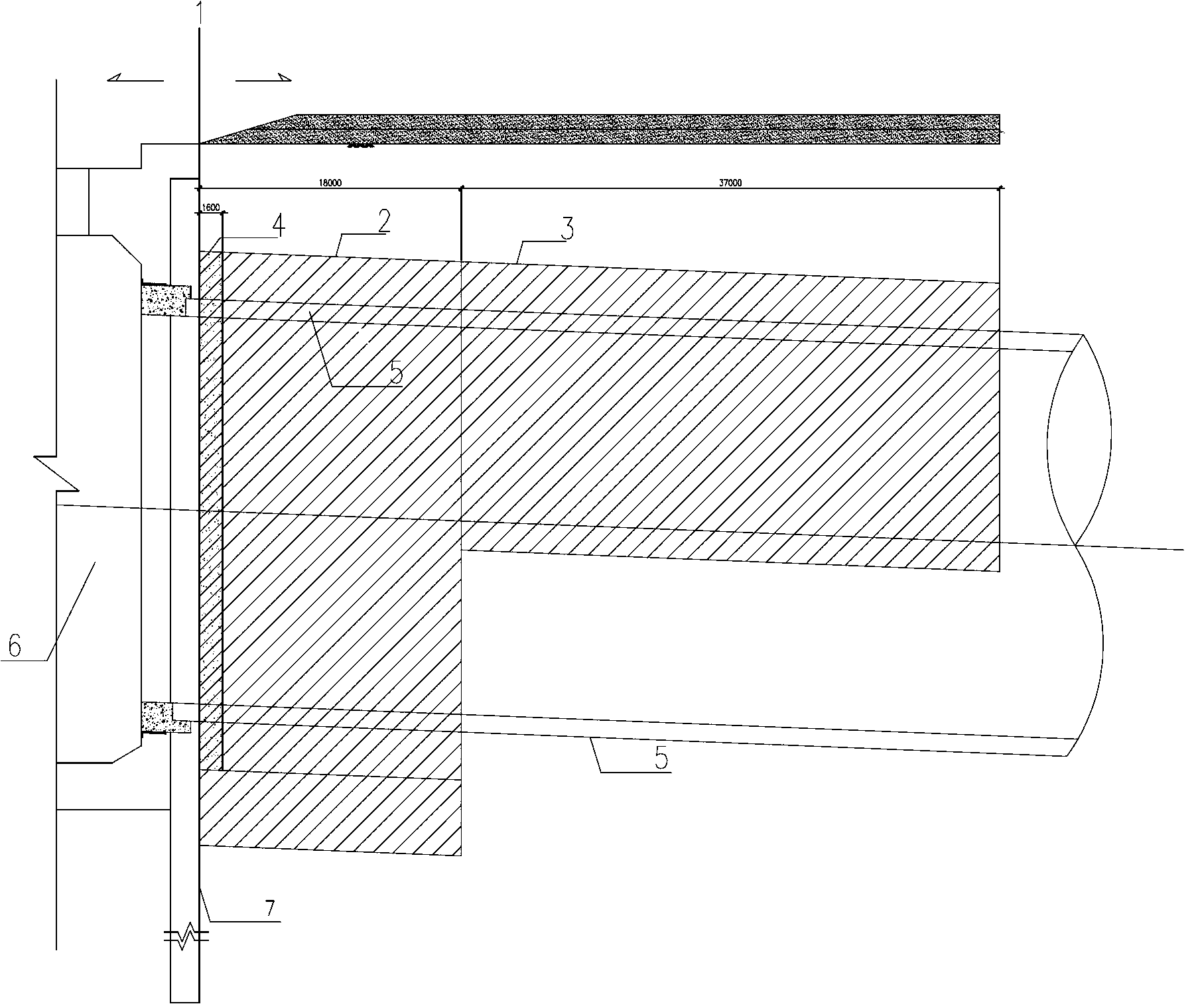

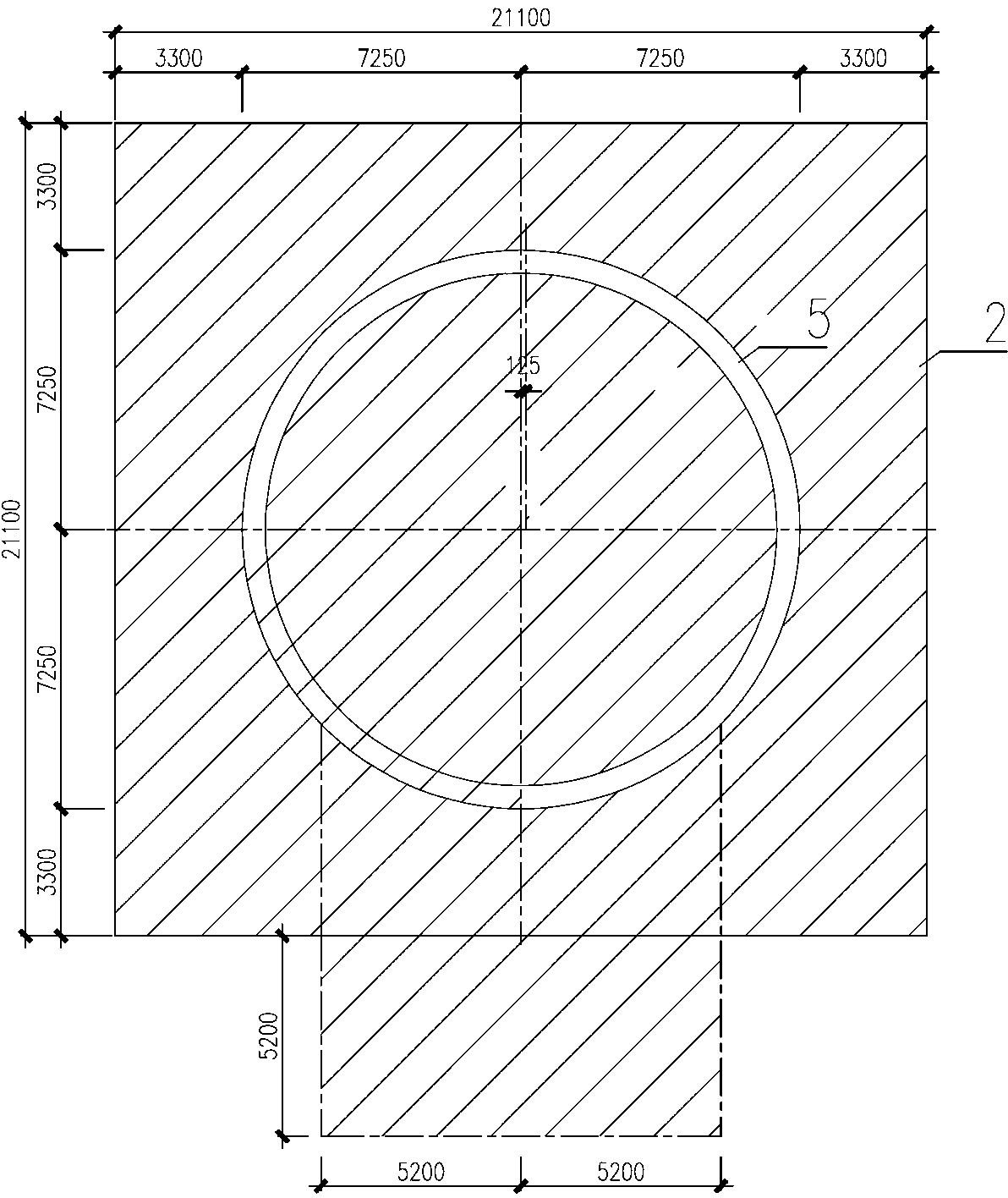

[0029] like Figures 1~5 As shown in the figure, the shield tunnel shallow covering soil originating method of the present invention comprises the following steps:

[0030] 1) Use rotary jetting piles or stirring piles to reinforce the full-section of the stratum traversed by the shield in the starting section. The thickness of the full-section reinforcement 2 is 2 to 3 meters longer than the length of the shield machine, which is 16.4 meters in this embodiment;

[0031] 2) With the end of the full-section reinforcement 2 as the boundary, along the shield tunneling direction, carry out portal reinforcement to the stratum. The thickness of the portal reinforcement 3 is 55 meters, and the full-section reinforcement 2 and portal reinforcement 3 are reinforced. The ground is covered with back pressure within the scope;

[0032] 3) Then us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com