Closed-type liquid-gas conversion engine with internal circulation

A liquid-gas conversion and internal circulation technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of safety concerns, carbon dioxide pollution of the atmospheric environment, etc., and achieve the effect of volume reduction and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

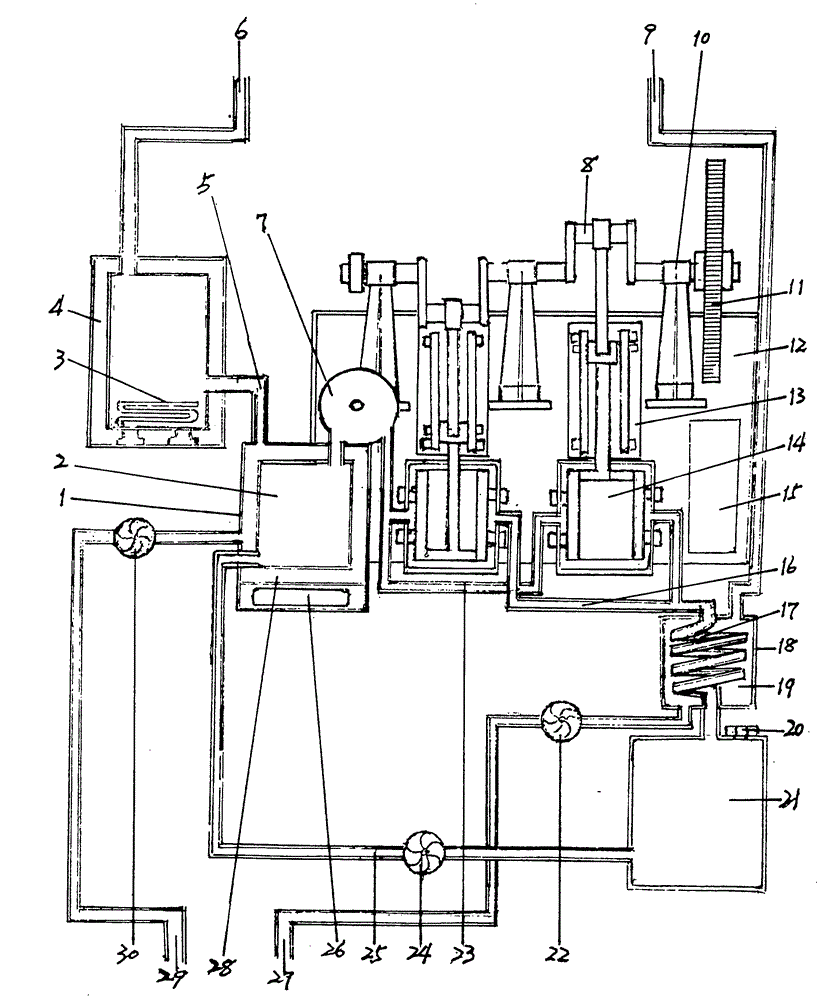

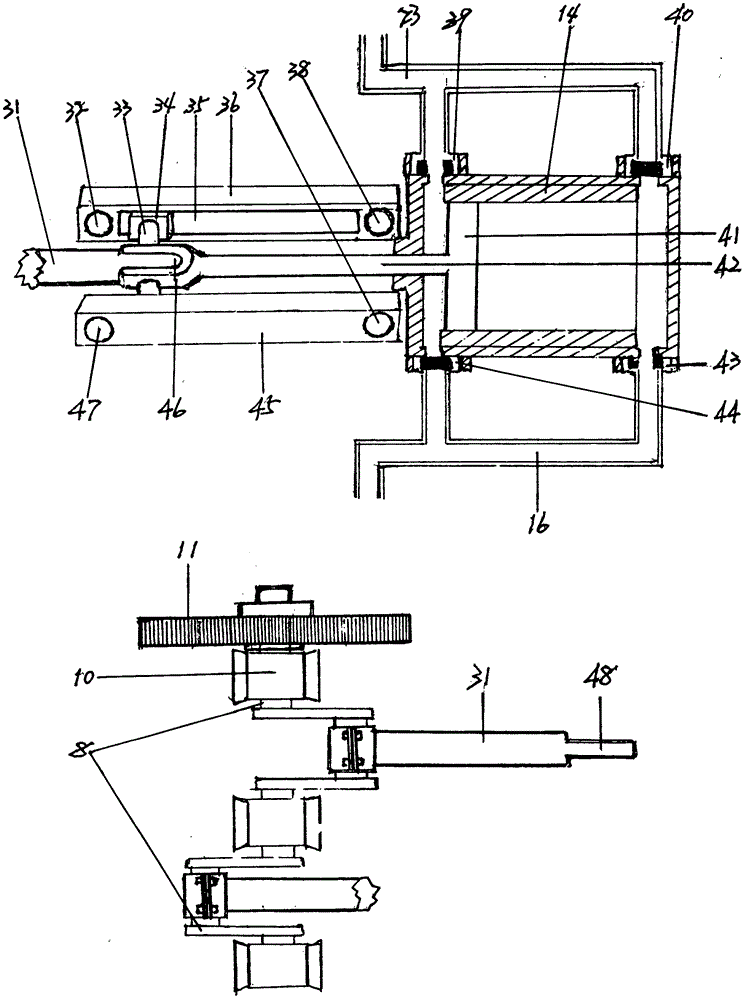

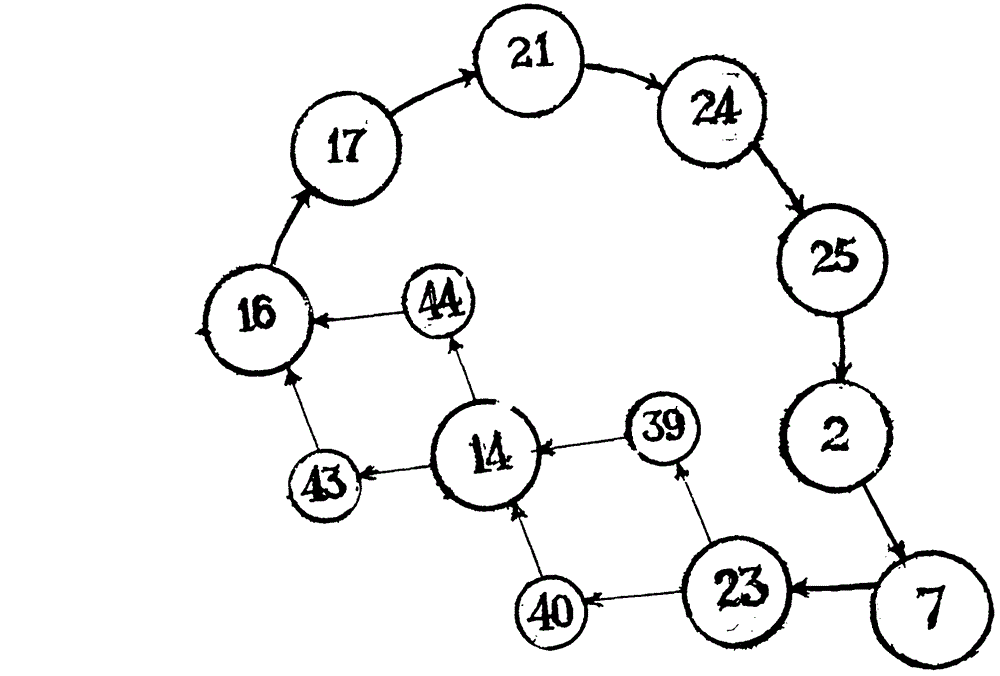

[0012] exist figure 1The hot water tank (4) in the tank is made of stainless steel with a hot water inlet pipe (6) at the top, a hot water output pipe (5) at the bottom of one side, and an electric heating tube (3) at the bottom of the tank. The two boxes are nested, and the middle of the interlayer is a vacuum box with heat preservation function for storing hot water. The hot water in the hot water tank (4) can be heated by the electric heating pipe (3), and can also be supplied by a solar water heater. If the hot water temperature is normal, the electric heating tube (3) will automatically cut off the power, but the electric heating tube will automatically turn on the power to heat the hot water again when the temperature of the hot water is lowered to the standard. The hot water tank (4) is connected to the gasification tank (1) through the hot water output pipe (5). On the hot water output pipe (5) of the side below, the mouth of pipe below the side of the gasification t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com