Wind turbine generator control method, controller and control system of wind turbine generator

A technology of wind turbines and control methods, which is applied in the control of wind turbines, wind power generation, wind turbines, etc., which can solve problems such as difficult to accurately track torque values, low utilization rate of wind energy, mismatched wind speed, etc., to solve the fatigue of the whole machine Loss of load and power generation, and the effect of improving wind energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

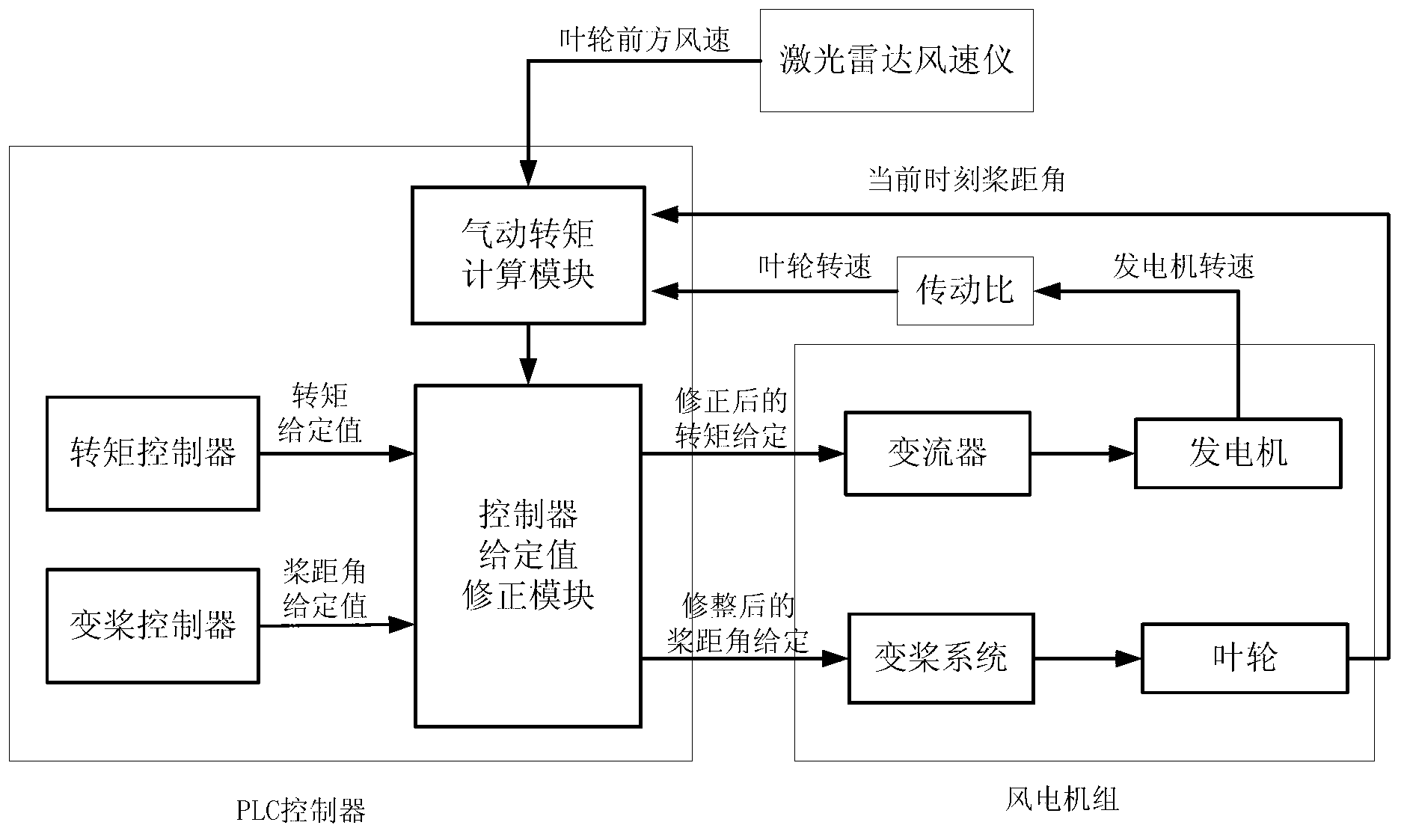

[0027] see figure 1 As shown, the present invention is a control system of a wind turbine, including a laser radar anemometer, a PLC controller and a wind turbine.

[0028] Among them, the laser radar anemometer is installed on the hub to measure the airflow velocity at a distance of 2-3 times the diameter of the front impeller.

[0029] The wind turbine mainly includes a generator, a converter, a pitch system and an impeller, and the generator and the impeller are controlled according to the corrected torque given value and pitch angle given value output by the PLC controller.

[0030] The PLC controller, that is, the controller of the wind turbine of the present invention, has a built-in torque controller, a pitch controller, an aerodynamic torque calculation module and a controller given value correction module. According to the control method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com