Method and system for diagnosing bearing faults of large-size wind turbine bearing

A technology for fault diagnosis of wind turbines, applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., can solve problems such as limitations, lack of adaptability, and inability to achieve diagnosis well, achieve fast speed, and avoid sudden accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

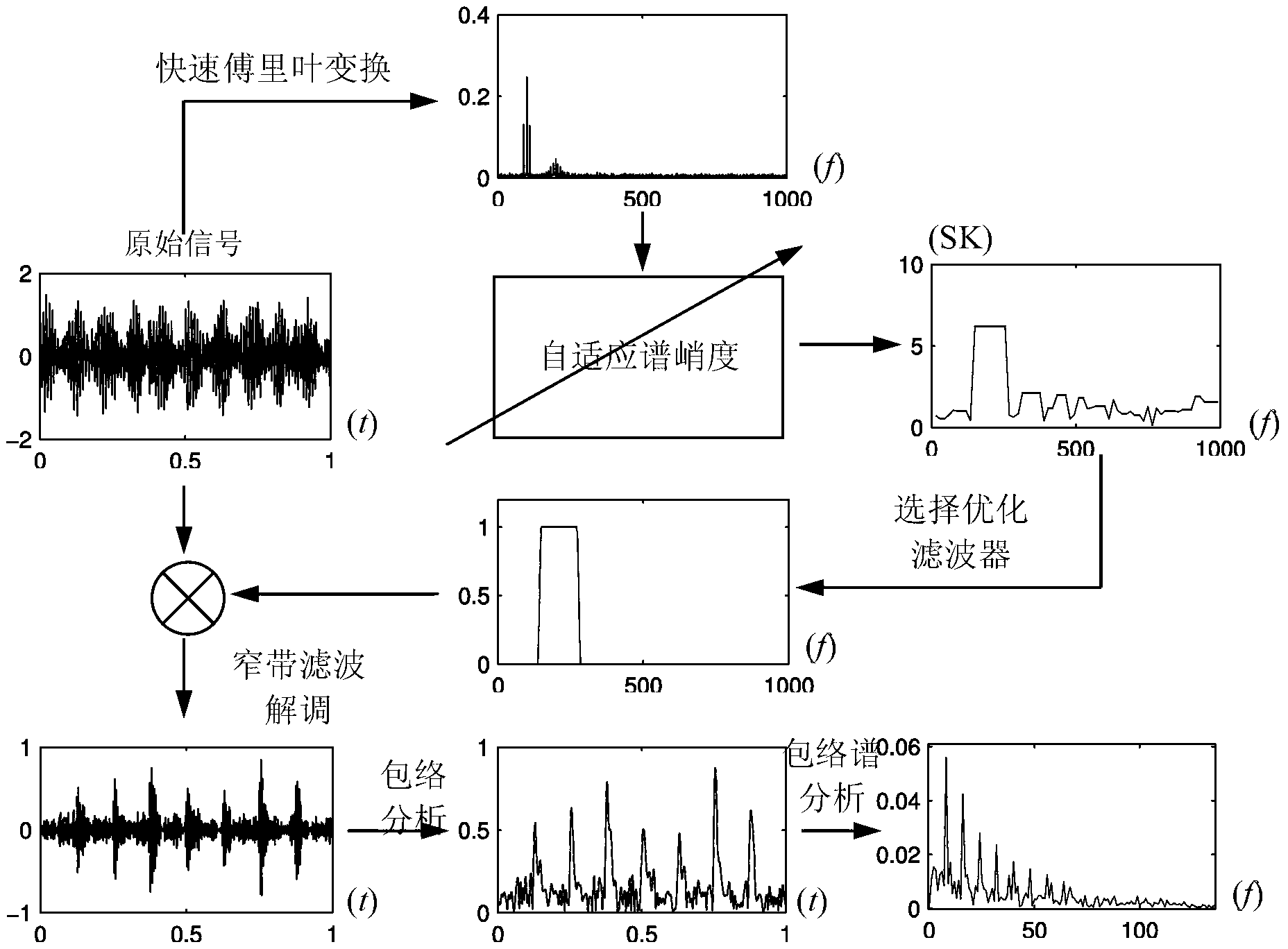

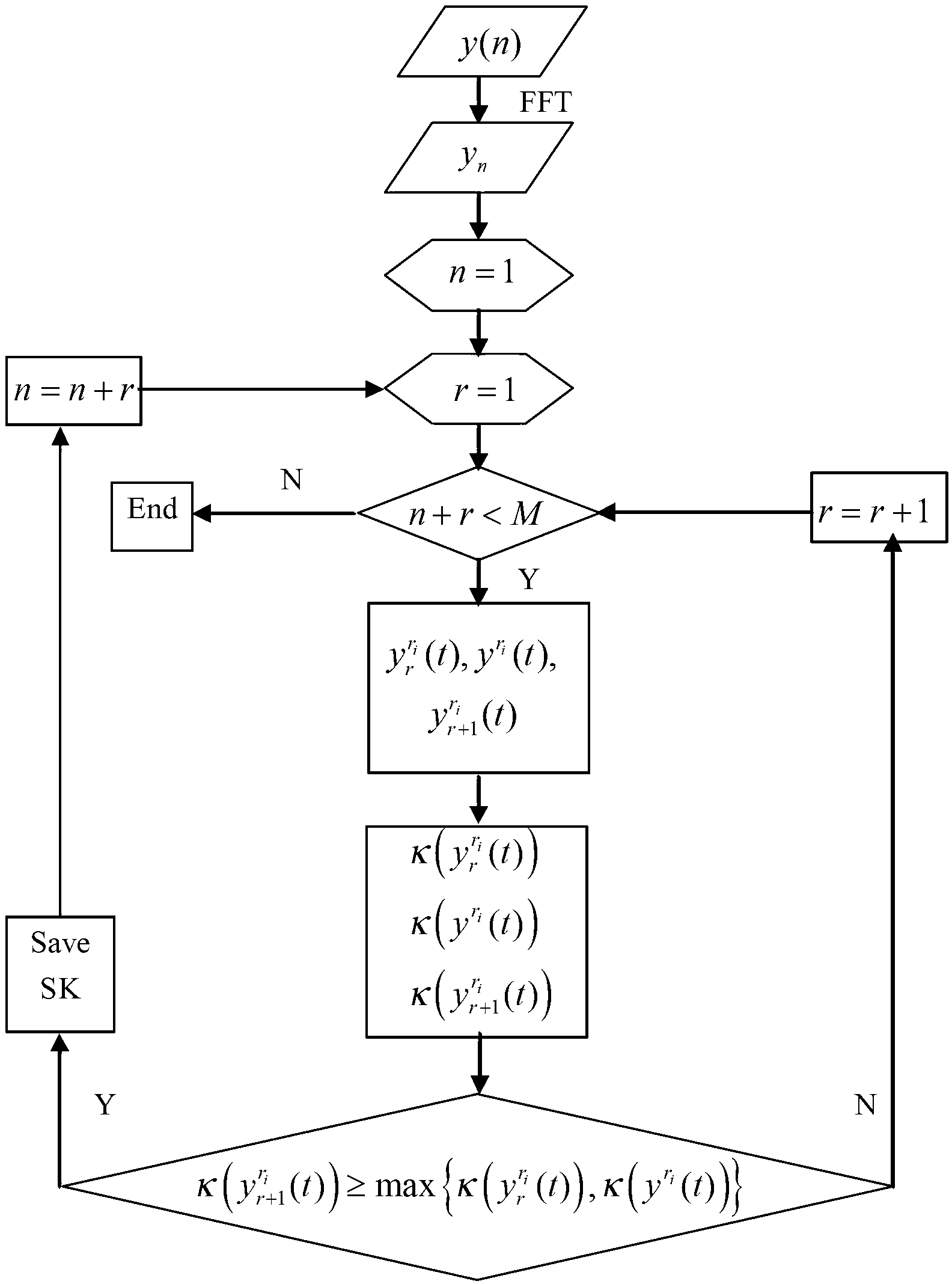

[0041] see figure 1 , a large-scale wind turbine bearing fault diagnosis method of the present invention comprises the following steps:

[0042] (1) Install an acceleration sensor on the bearing seat of the wind turbine to be tested to pick up the original vibration signal of the main shaft bearing.

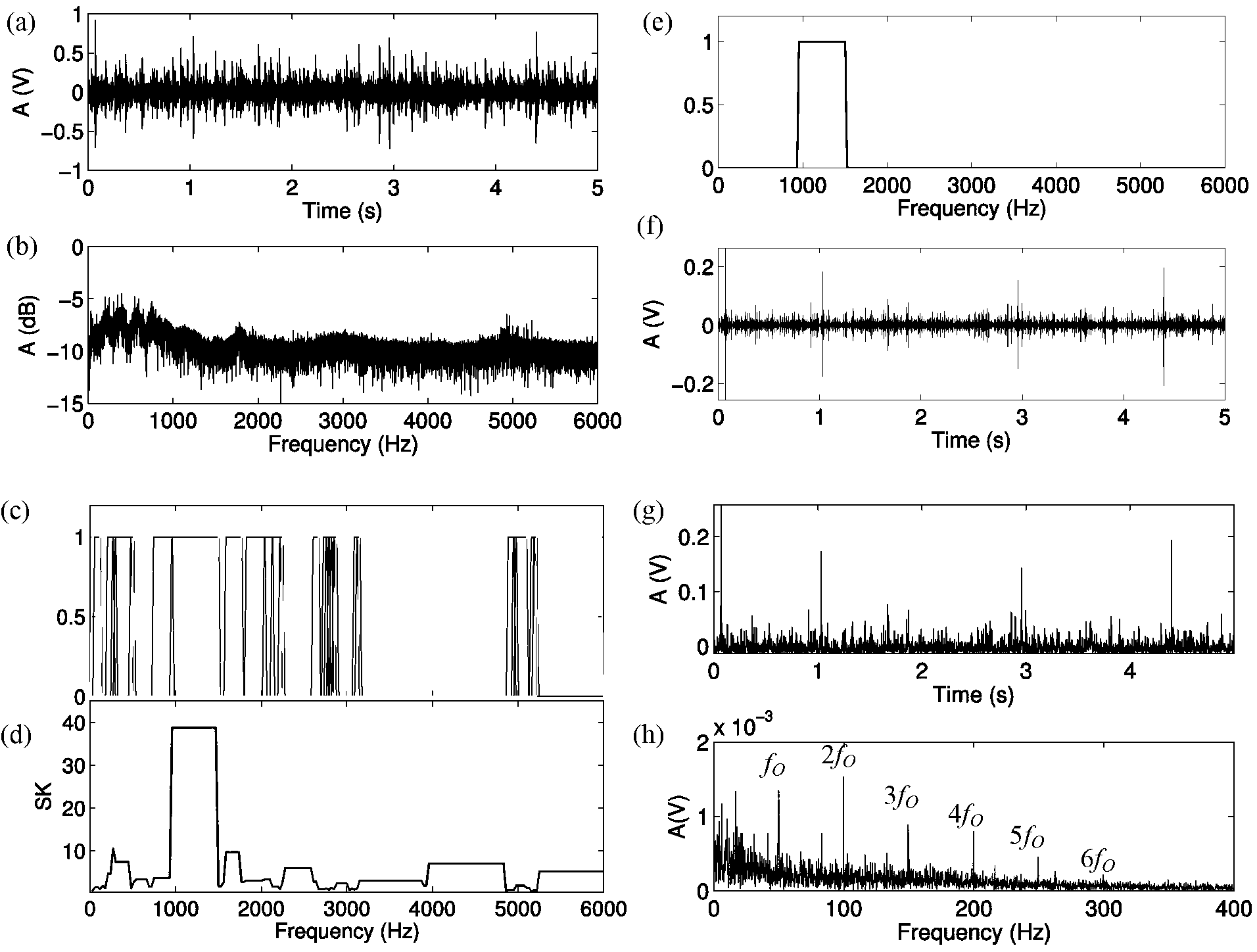

[0043]The invention obtains the steady-state signal by re-sampling the typical non-stationary operation signal in the angle domain. In this example, the model of the wind turbine is NEG-MiconNM1000 / 60, the rated power is 1070kw, and the maximum rotation speed is 1500rpm. Affected by the working environment, wind turbines often work under the influence of alternating loads, showing non-stationary and nonlinear characteristics of operation; these bring many difficulties to the extraction of bearing fault features. In this example, two piezoelectric acceleration vibration sensors, axial and radial, are installed directly under the bearing seat of the bearing to collect vibration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com