Low-temperature co-fired ceramic stacking protective element and manufacturing method thereof

A technology of low-temperature co-fired ceramics and protection components, which is used in electrical components, fuse manufacturing, emergency protection devices, etc., can solve the problems of difficult to control the length of the fuse link, poor consistency of the fusing characteristics, and difficult to control the size of the micro-hole, so as to improve the design The effect of specification limit, good size consistency, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

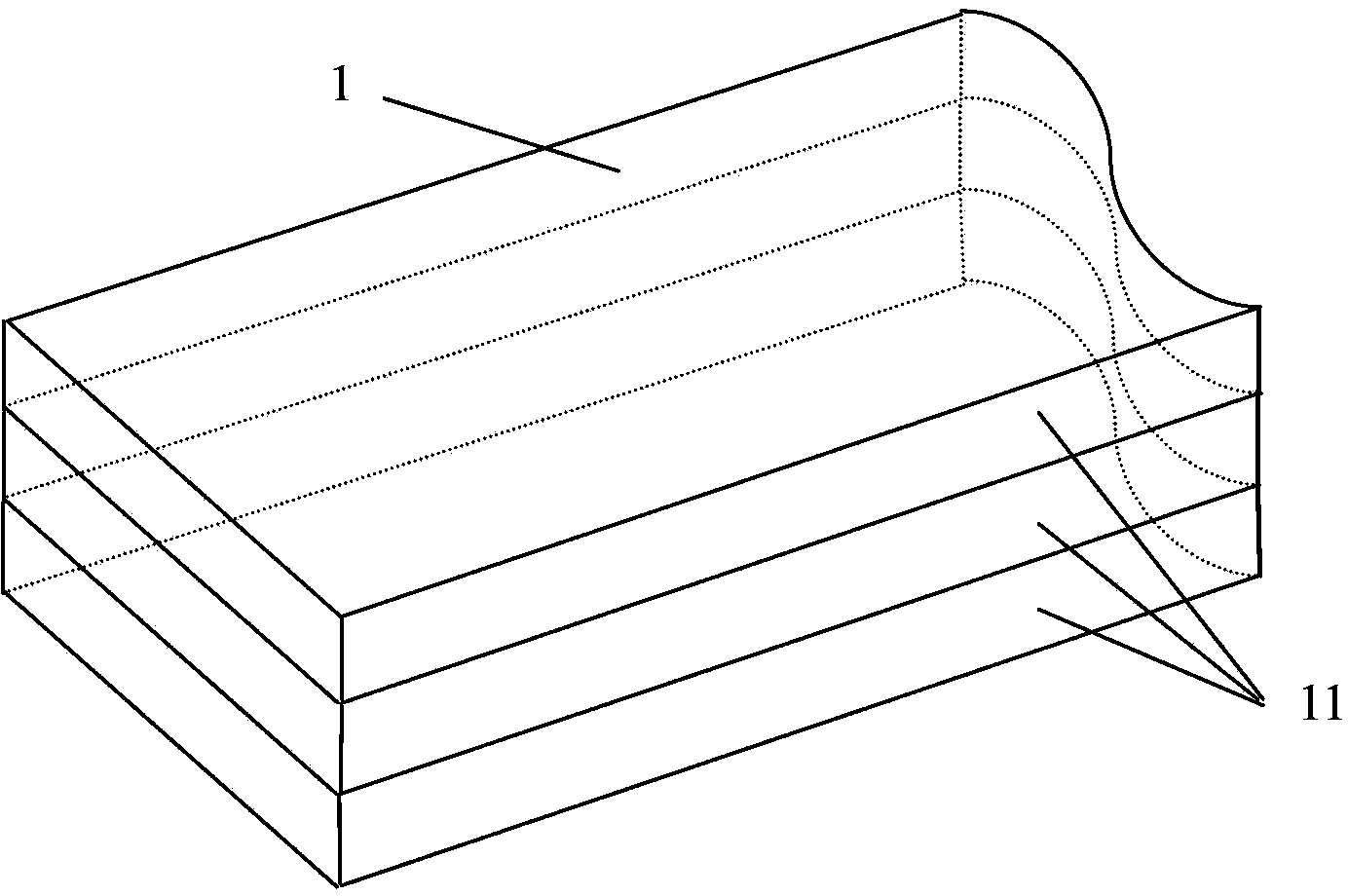

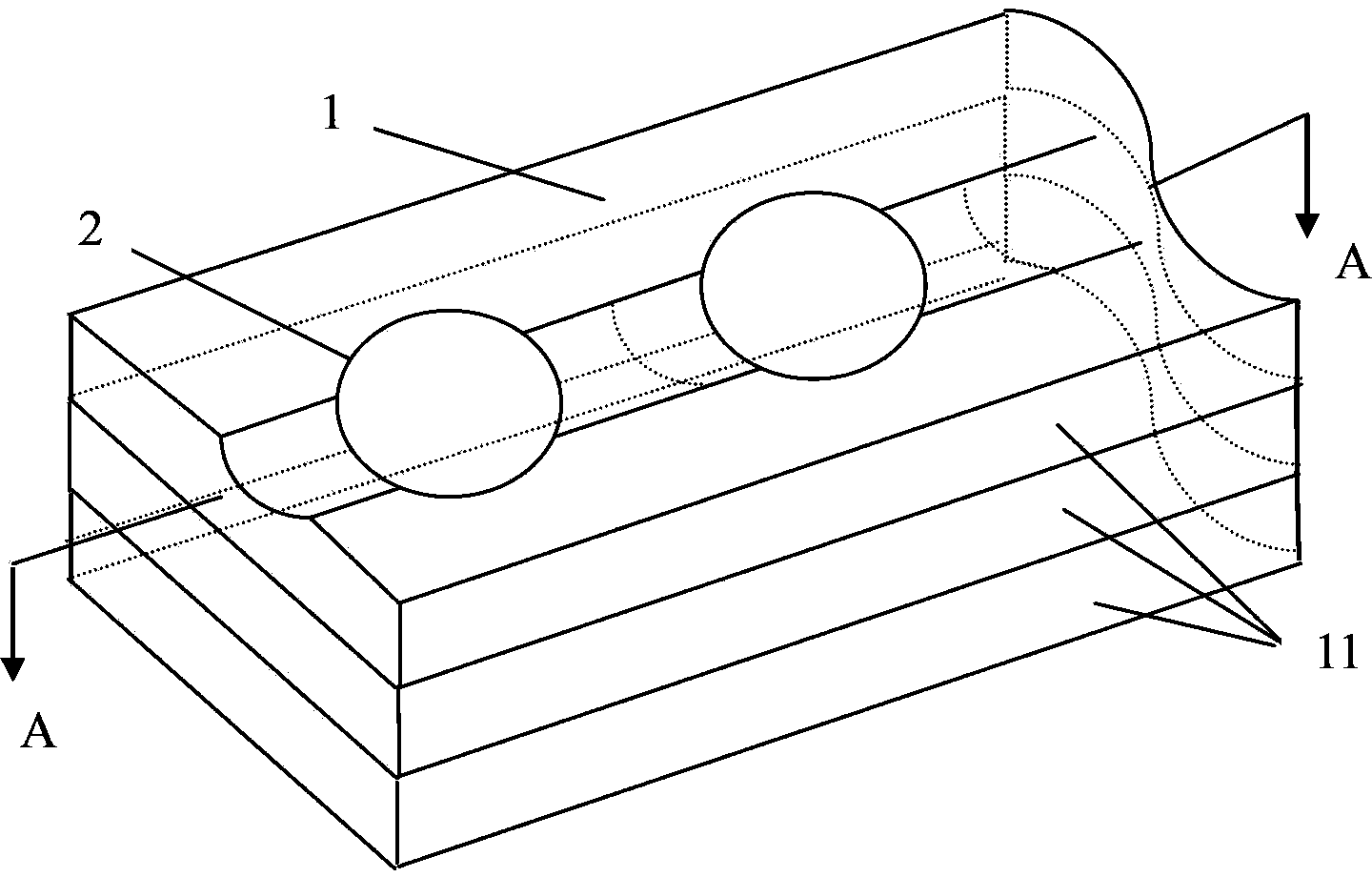

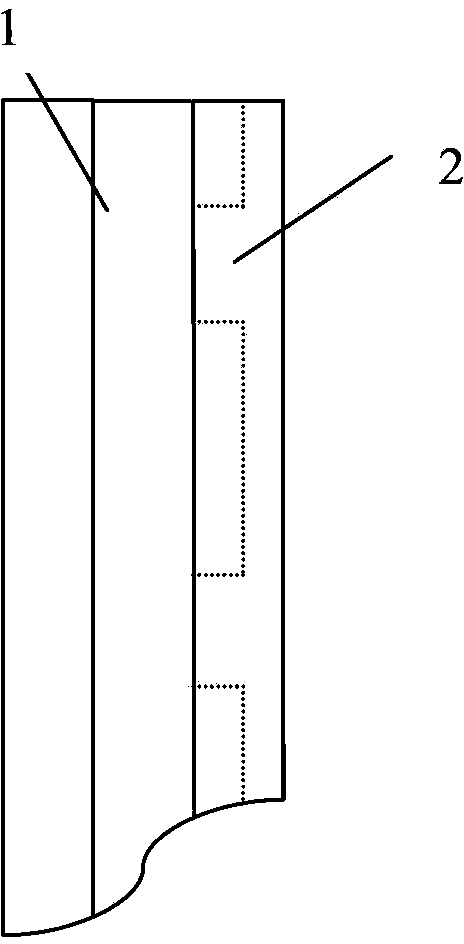

[0032] An embodiment of a low temperature co-fired ceramic stack protection element: as Figure 13 A low temperature co-fired ceramic stack protection element 4 shown includes a ceramic substrate 1 , a melt layer 3 and a terminal electrode 5 . Such as figure 1 As shown, the ceramic substrate 1 is formed by stacking ceramic diaphragms 11; the ceramic diaphragm 11 is formed by casting process of LTCC ceramic slurry; as figure 2 , image 3 As shown, a punching groove 2 is provided on the ceramic substrate 1, such as Figure 4 As shown, the stamping groove 2 is filled with LTCC porous ceramic slurry 21 or pore-forming agent slurry 22 through a thick film printing process; the melt layer 3 is composed of an LTCC ceramic diaphragm 11 and an electrode pattern 31, as Figure 5 As shown, the electrode pattern 31 includes two parts, the lead-out electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com