Three-dimensional spiral inductor and forming method thereof

A spiral inductance, three-dimensional technology, applied in the direction of inductors, fixed inductors, fixed signal inductors, etc., can solve the problems of the large area occupied by the plane spiral, the large area of the semiconductor substrate, and the low Q value, so as to improve the Q value, The effect of reducing energy consumption and reducing the amount of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

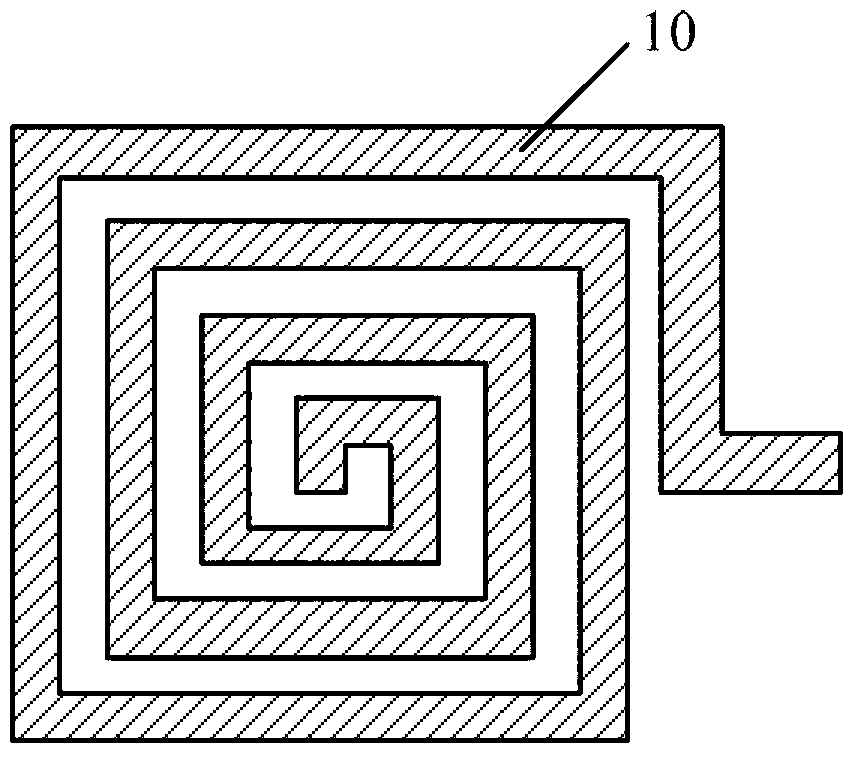

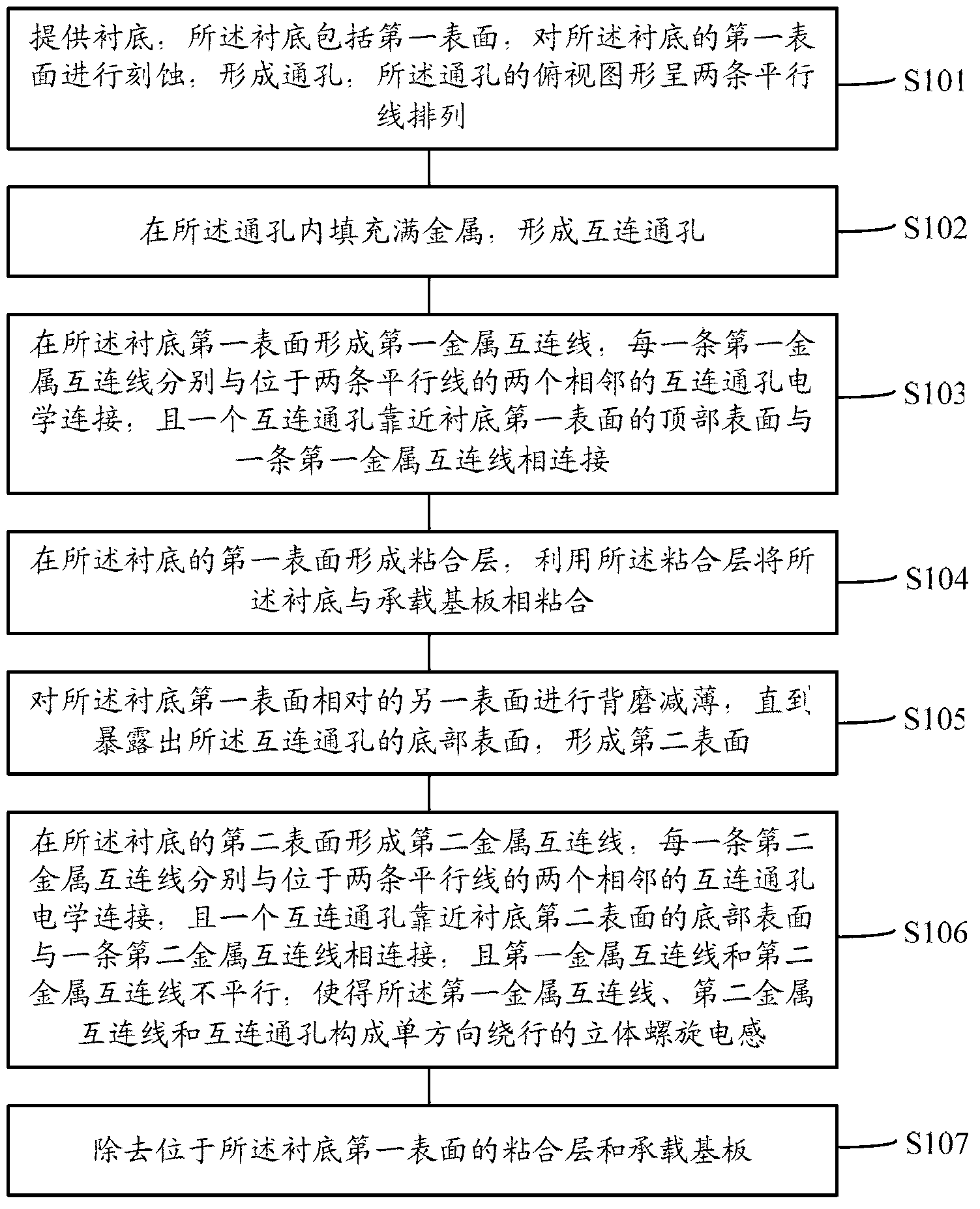

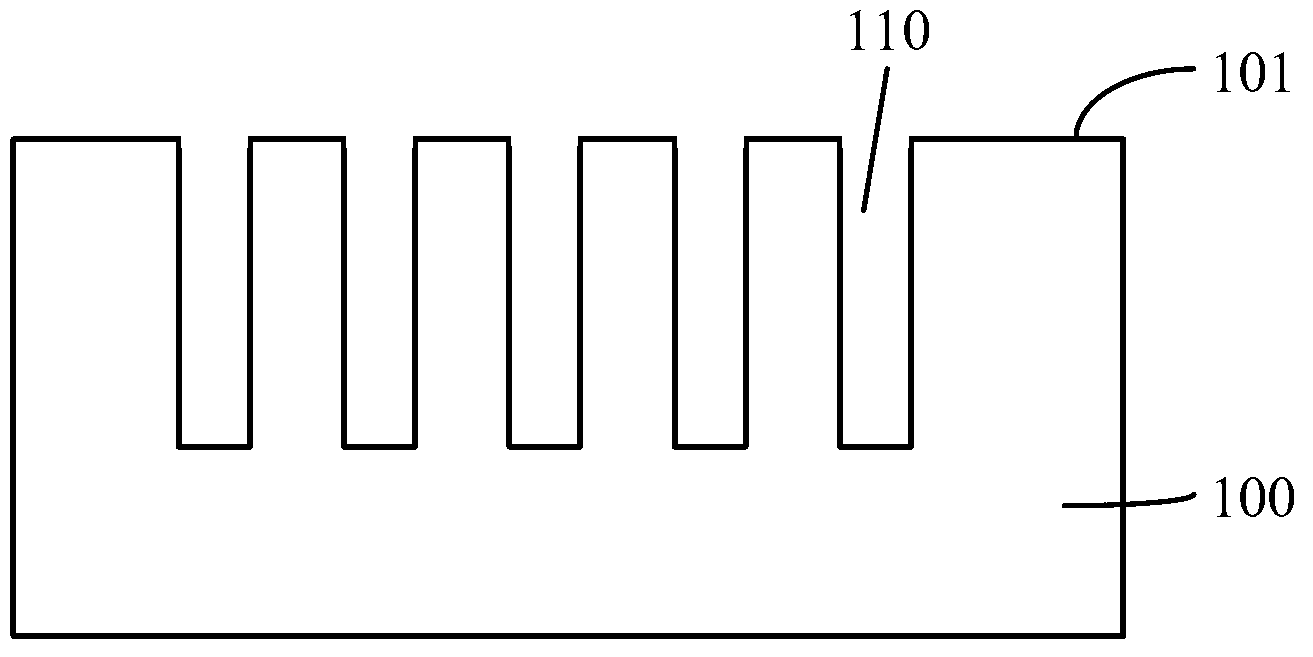

[0031] Since the inductance of the inductor is related to the number of turns of the inductor coil, the more the number of turns, the greater the inductance; the inductance of the inductor is also related to the area in the middle of the coil, and the larger the area in the middle of the coil, the greater the inductance. In the prior art, the inductors formed on the semiconductor substrate are mostly planar inductors, which are in the shape of a planar spiral. In order to increase the inductance of the inductor, the number of coil turns required for the inductor is large. Even if the multi-layer planar spiral inductors are stacked, The Q value of the inductor can be increased, but the area occupied by the inductor is still large, and because the middle area of each coil in the planar spiral coil is different, the middle area of the coil inside the inductor is very small, which is not conducive to increasing the inductance of the inductor.

[0032] To this end, the inventor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com