Flyback-type quick-start LED (Light-Emitting Diode) drive circuit structure

A technology of LED driving and fast startup, which is applied in the layout of electric lamp circuits, electric light sources, lighting devices, etc., can solve the problems of difficulty in achieving a compromise solution between the driving efficiency and startup time of LED driving circuits, and high power consumption, so as to improve the driving efficiency. , the effect of reducing power consumption and reducing start-up resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the technical aspects of the present invention more clearly, the following examples are given in detail.

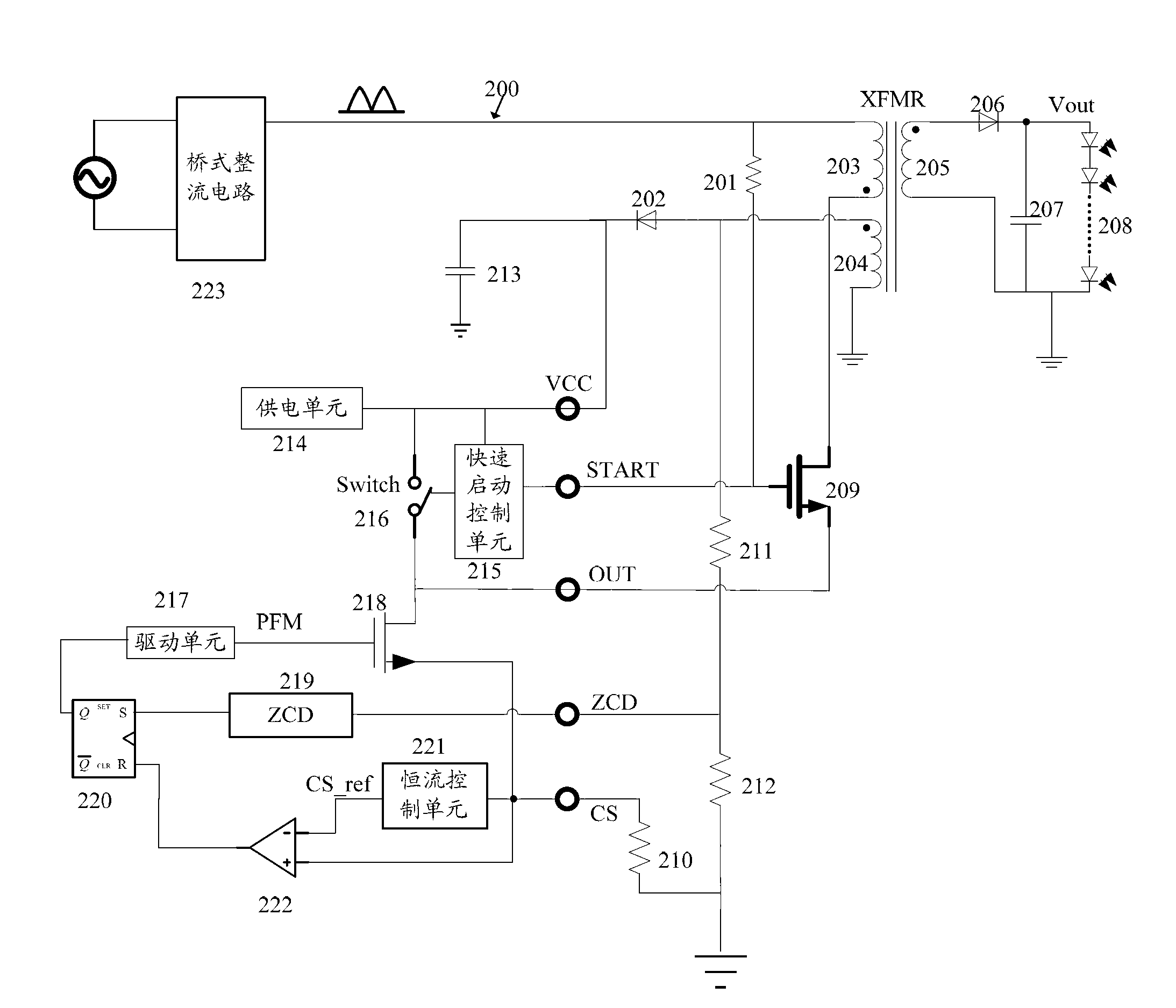

[0025] see figure 2 As shown, the present invention is a schematic diagram of the structure of the flyback fast-start LED driving circuit of the present invention.

[0026] In one embodiment, the circuit structure includes a voltage input module, a load output module, a transformer, a feedback control circuit module and a quick start control circuit module.

[0027] Such as figure 2 As shown, wherein the transformer includes a primary winding 203 , a secondary winding 205 and a secondary winding 204 . The voltage input module is connected to the opposite terminal of the primary winding 203 of the transformer. The load output module is connected to the secondary winding 205 of the transformer. The feedback control circuit module is respectively connected to the secondary winding 204 and the fast start control circuit module. The quick sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com