IGBT (Insulated Gate Bipolar Transistor) water cooling radiator

A radiator and water-cooled technology, applied in the field of IGBT water-cooled radiators, can solve the problems of large resistance, difficulty in meeting the heat dissipation requirements of high-power IGBTs, and reduce the heat dissipation area, so as to increase disturbance, improve heat dissipation efficiency, and increase heat dissipation area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

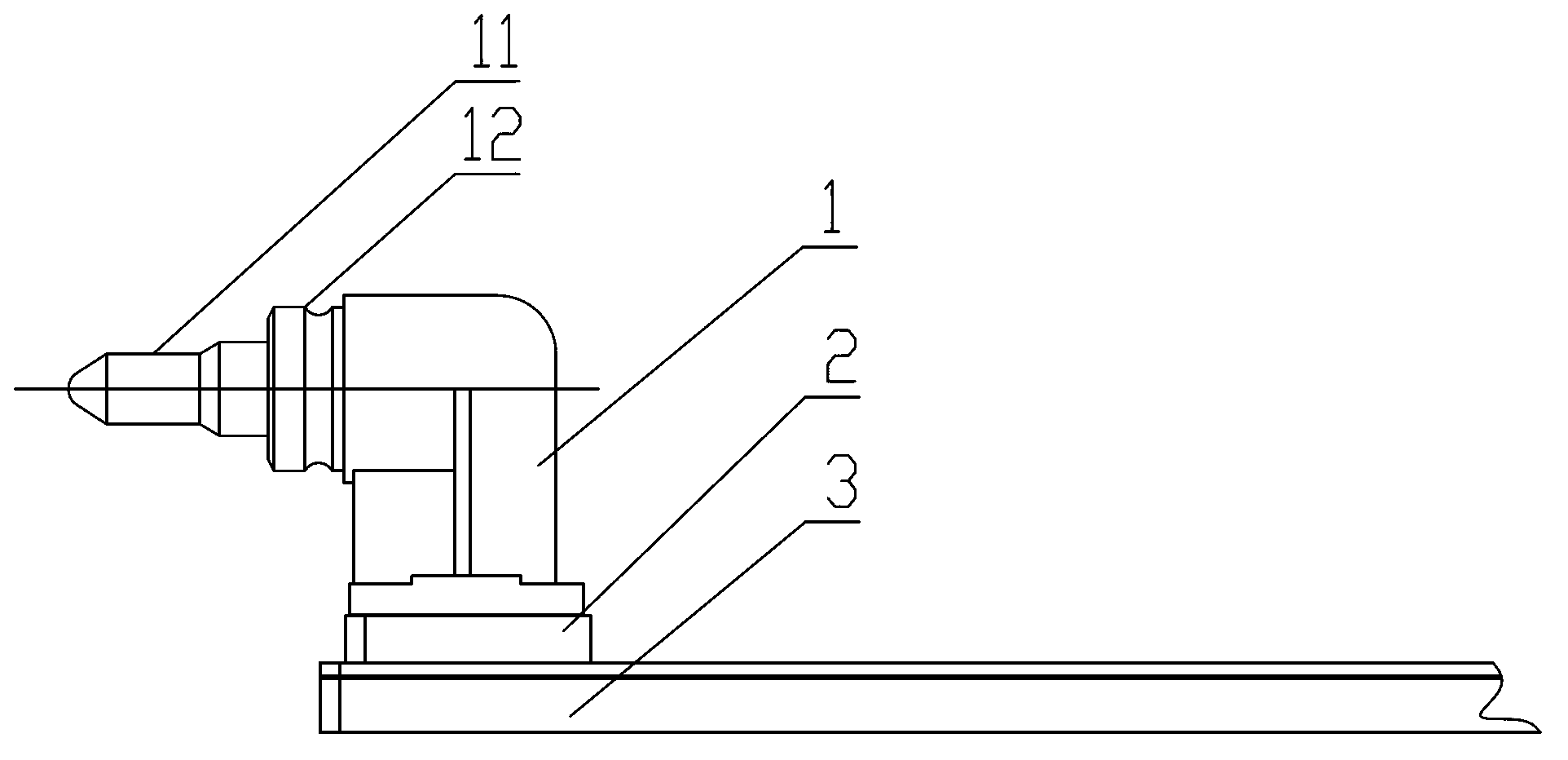

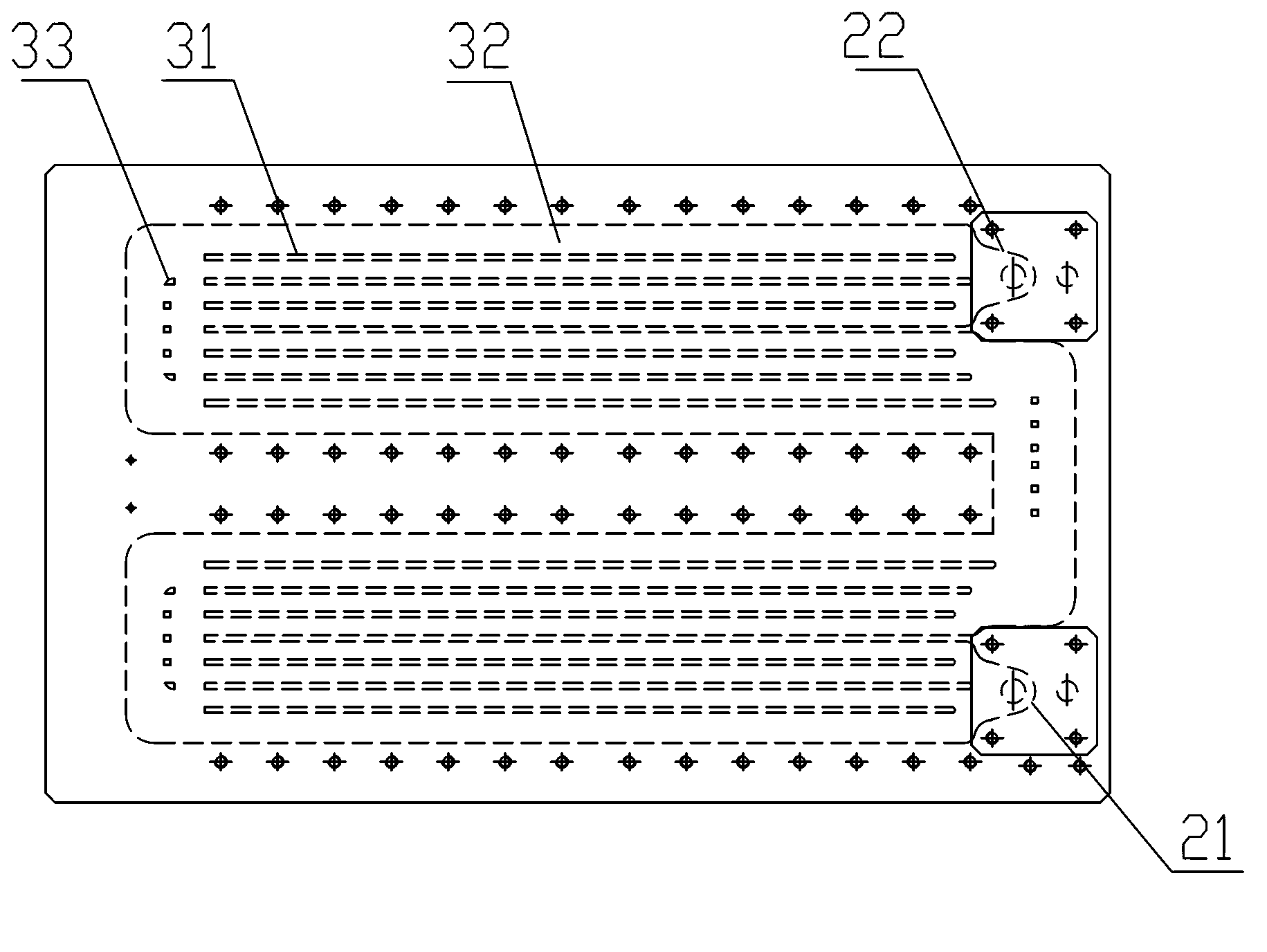

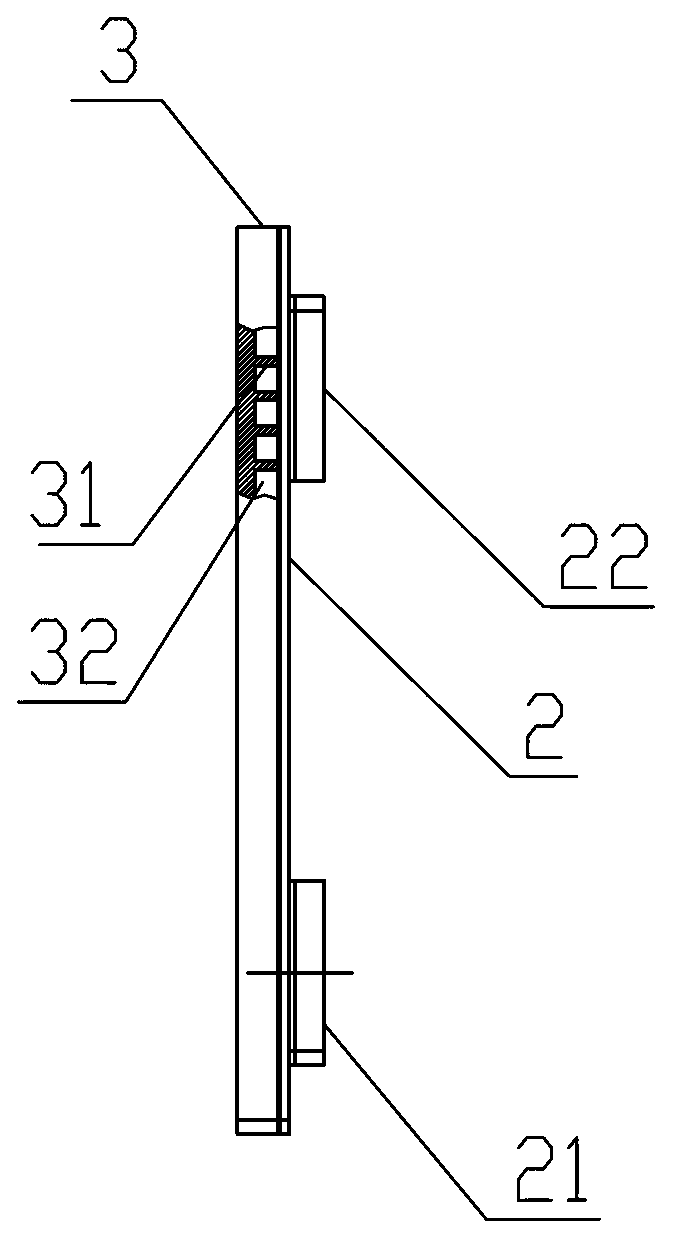

[0014] Such as figure 1 As shown, an IGBT water-cooled radiator includes a water inlet and outlet joint 1, a flat base plate 2 and a groove base plate 3. The inlet and outlet joints 1 are provided with two guide columns 11 for quick plugging and unplugging of water pipes and two inlet and outlet joints. Water port 12, two water inlet and outlet ports 12 communicate with the water inlet 21 and the water outlet 22 that are arranged on the flat base plate 2 and communicate with the two ends of the main channel on the described tank base plate 3 respectively (as image 3 shown). In the slot substrate 3 (as figure 2 As shown), a main channel with a plurality of flow channel baffles 31 is milled out for the cooling liquid to flow through, and the flow channel baffles 31 are integrated with the groove base plate 3, that is, formed by milling; The flow channel baffle plate 31 divides the main channel into a plurality of sub-flow channels 32, and the number of the sub-flow channels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com