Liquid receiver combined with liquid separator for refrigeration cycle and manufacturing method thereof

A gas-liquid separator, refrigeration cycle technology, applied in refrigeration and liquefaction, compressors with reversible cycle, refrigerators, etc., can solve problems such as failure of smooth compressor damage, poor separation, etc. The effect of reducing defect rate and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

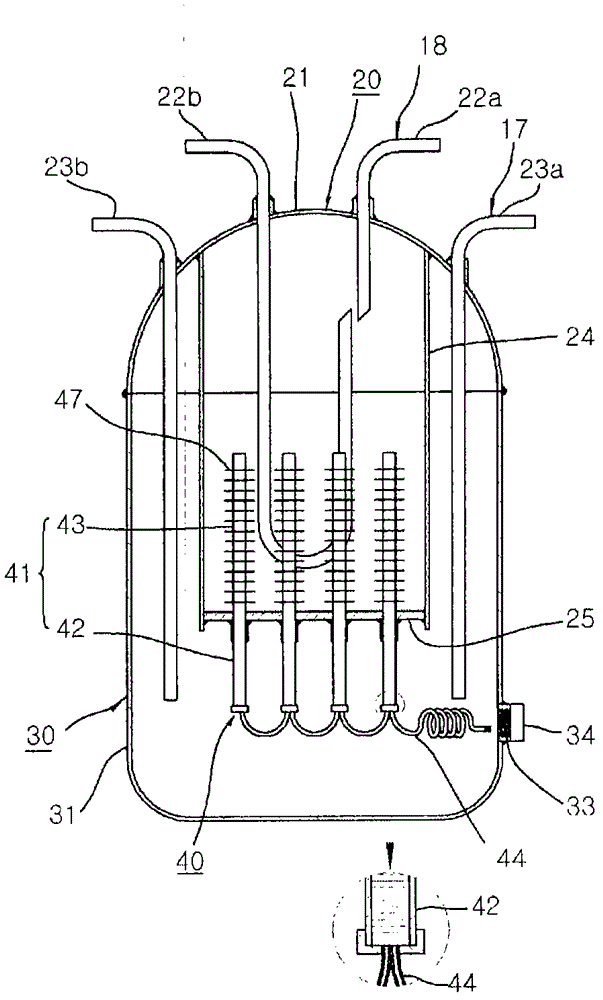

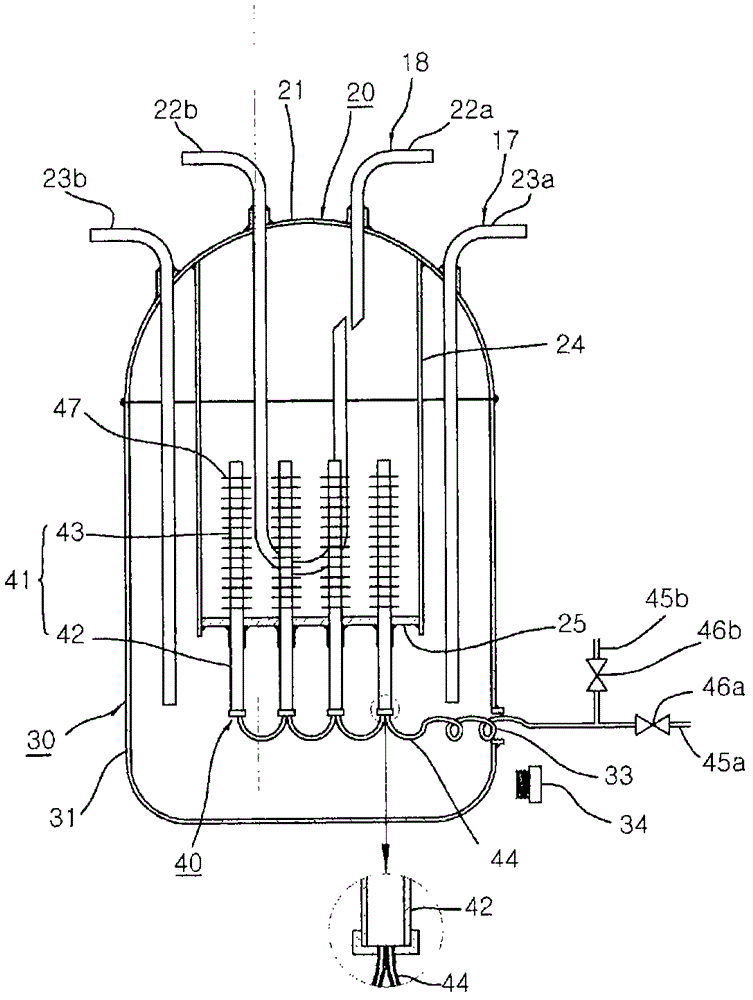

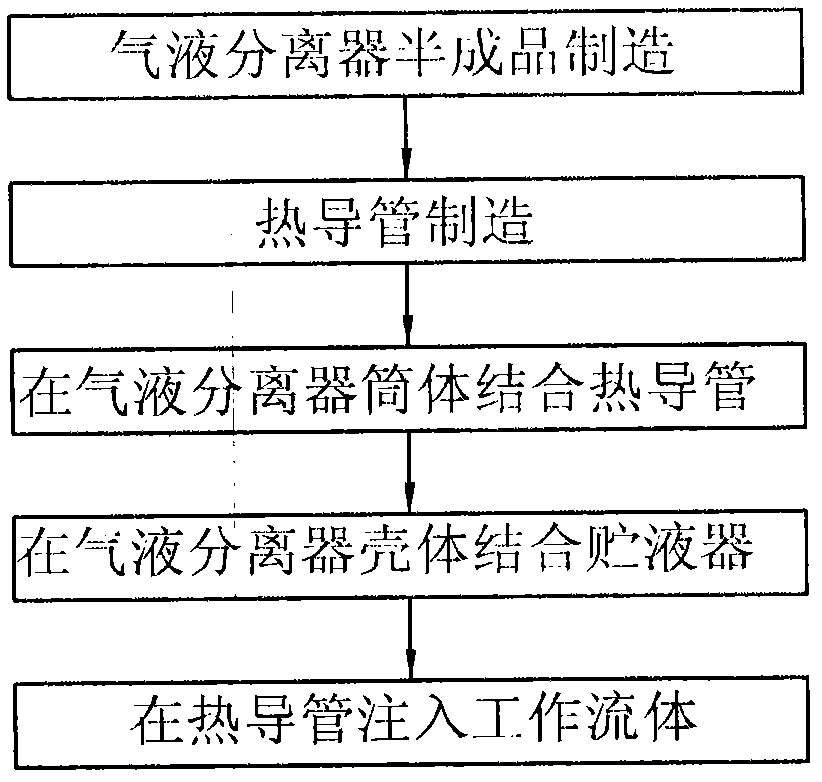

[0023] figure 1 is a cross-sectional view of an embodiment of the present invention, figure 2 is a state diagram before the heat pipe injects the working fluid in the embodiment of the present invention, image 3 is a manufacturing engineering drawing of an embodiment of the present invention, Figure 4 It is an installation example diagram of an embodiment of the present invention, that is, the structure of the present invention is roughly divided into a gas-liquid separator 20 , a liquid reservoir 30 and a heat pipe 40 .

[0024] The gas-liquid separator 20 is composed of a vertical refrigerant vapor inflow conduit 22a and a hook-shaped refrigerant vapor discharge conduit 22b formed at the opposite part after the arc-shaped shell 21 is welded and connected to cut off the suction conduit 18 halfway. ; The refrigerant vapor inflow co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com