Light emitting diodes

A technology of light-emitting device and emission layer, applied in the field of white light LED, can solve the problems of color reproduction blue tone, LED failure, degradation of optical performance of emission layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

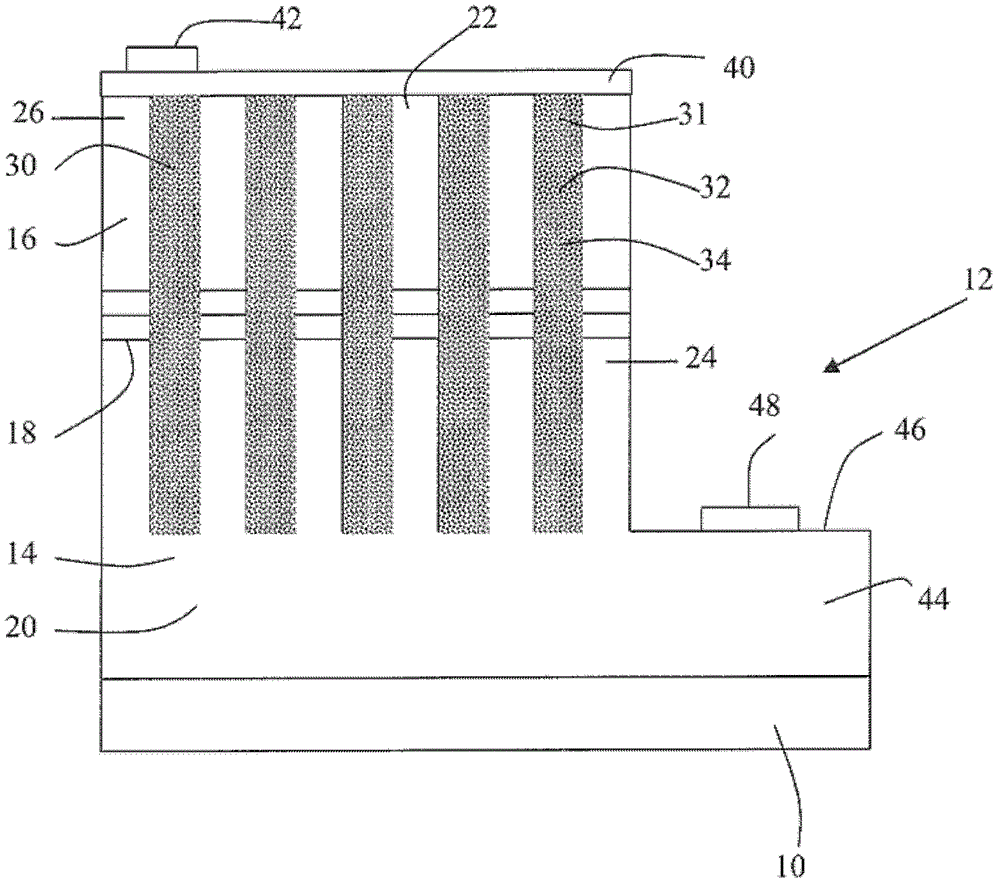

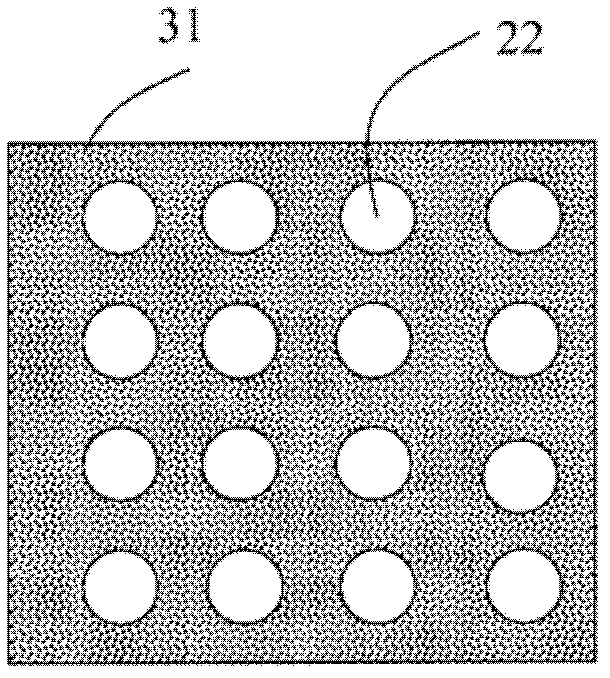

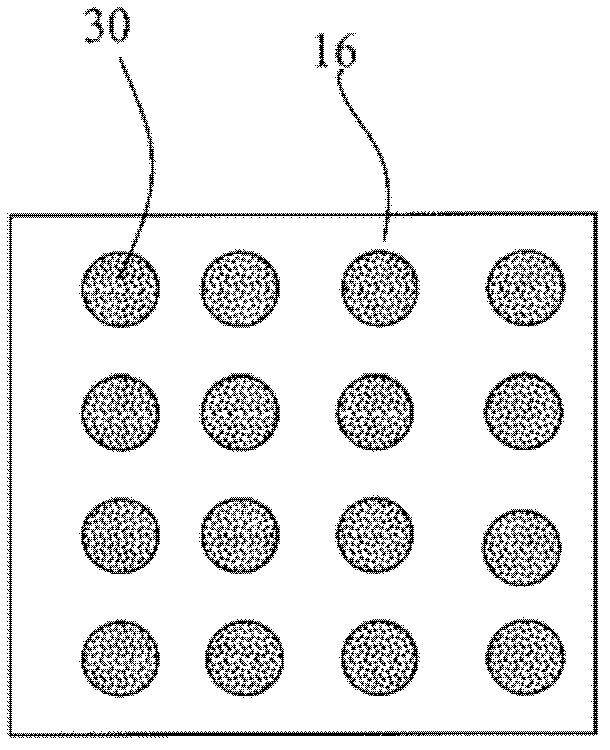

[0043] see figure 1 , a light-emitting device according to an embodiment of the invention comprises a substrate 10 , which in this case comprises a layer of sapphire, wherein a semiconductor diode system 12 is formed on the substrate 10 . Diode system 12 includes a lower layer 14 and an upper layer 16 with an emitter layer 18 therebetween. The lower layer 14 is an n-type layer formed of n-doped gallium nitride (n-GaN), and the upper layer 16 is a p-type layer formed of p-doped gallium nitride (p-GaN). The emissive layer in this embodiment is formed from In x Ga 1-x In of the N quantum well (QW) layer x Ga 1-x N and In forming the barrier layer y Ga 1-y N is formed (where x>y, x or y is from 0 to 1). These therefore provide multiple quantum wells within the emissive layer 18 . In another embodiment, there is a single In that forms a single emissive layer z Ga 1-z N layers (z from 0 to 1).

[0044]When electrical current is passed through semiconductor diode system 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com