Method for forming handmade-simulated dumplings

A molding method and hand-imitating technology, which is applied in the field of imitating hand-made stuffing food molding of a mechanical molding stuffed food device, can solve the problems of high manufacturing cost, cumbersome molding method, and complicated structure of the molding device, and achieve easy folding and convenient elimination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

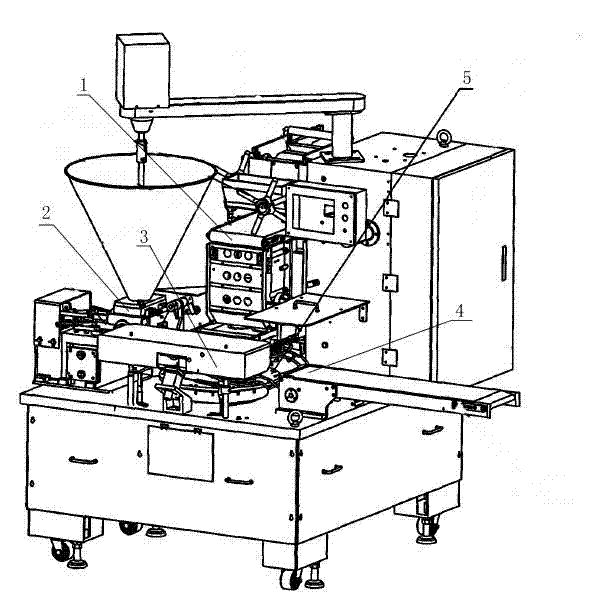

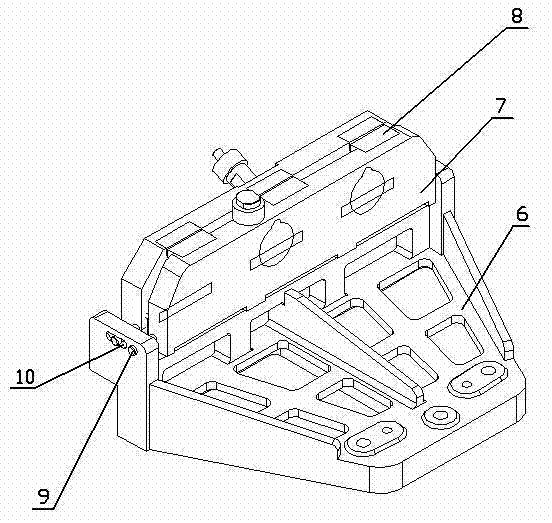

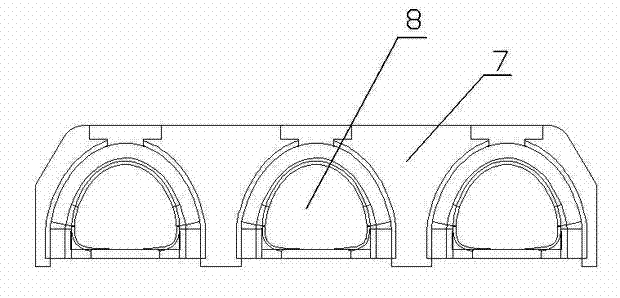

[0059] The forming device of the present invention is a flexible forming device for stuffed food 20, which includes a mold base 6, two templates 7, a flexible forming block 8 arranged on each template 7, and a rotary device that drives the template 7 and the flexible forming block 8 to rotate together. mechanism, the translation mechanism that drives the template 7 and the flexible forming block 8 to perform reciprocating translational movement together, the two templates 7 are connected with the mold base 6 through a rotating mechanism, and at least one template 7 is connected with a translation mechanism.

[0060] The template 7 is provided with a rotating mechanism, and the rotating mechanism is driven to rotate by the rotating drive mechanism; the rotating mechanism includes rotating shafts 9 respectively arranged at the bottom of the two templates 7, and both ends of the rotating shaft 9 are connected to the mold base 6 except for the structure of the rotating shaft 9 Besi...

Embodiment 2

[0072] A molding method imitating manual stuffing food 20, the dough is placed on the molding station of the food stuffing device at the annular station, the template 7 of the flexible molding device is turned over, and the outer edge is in an open and closed state, flexible The two flexible forming blocks 8 on the forming device move horizontally relative to each other, and the folded dough is gradually sealed and formed from the inside to the edge; the template 7 drives the two flexible forming blocks 8 to move relative to each other in the horizontal direction. Die base 6 is installed on the ring track of ring station food stuffing device, and moves along the ring track. A clamping mechanism 16 is provided above the mold base 6, and a conveyor belt 19 is provided on one side of the mold base 6. The clamping mechanism 16 includes a clamping arm, a left clamping block 17, a right clamping block 18, and a driving clamp. The clamping driving mechanism of the opening and closing...

Embodiment 3

[0074] A molding method imitating manual stuffing food 20, the dough is placed on the molding station of the food stuffing device at the annular station, the template 7 of the flexible molding device is turned over, and the outer edge is in an open and closed state, flexible The two flexible forming blocks 8 on the forming device move horizontally relative to each other, and the folded dough is gradually sealed and formed from the inside to the edge; the template 7 drives the two flexible forming blocks 8 to move relative to each other in the horizontal direction. The flexible forming device also includes a mold base 6, a rotation mechanism and a translation mechanism. The mold base 6 is installed on the annular station food stuffing device, and the two templates 7 are respectively provided with matching flexible forming block 8, and the two templates 7 are respectively connected to the mold base 6 through the rotating mechanism, the template 7 and the flexible forming block 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com