Continuous microwave curing equipment for vacuum pressure paint impregnation electrical equipment

A technology of vacuum pressure dipping paint and microwave curing, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, which can solve the problems of high energy consumption and the inability of curing device to operate continuously, so that the paint layer does not fall off. , high degree of automation, excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

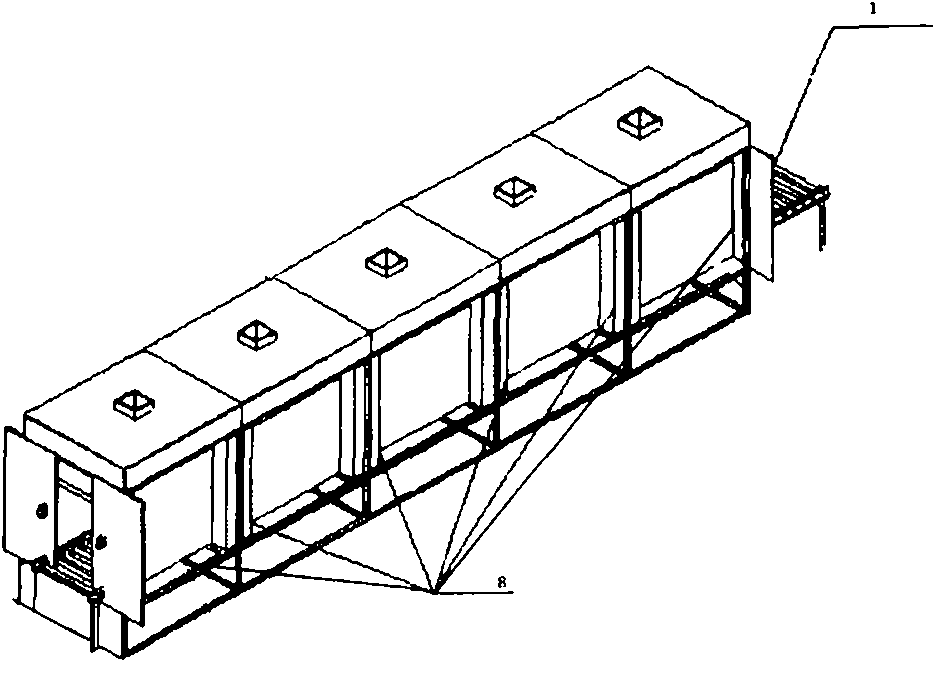

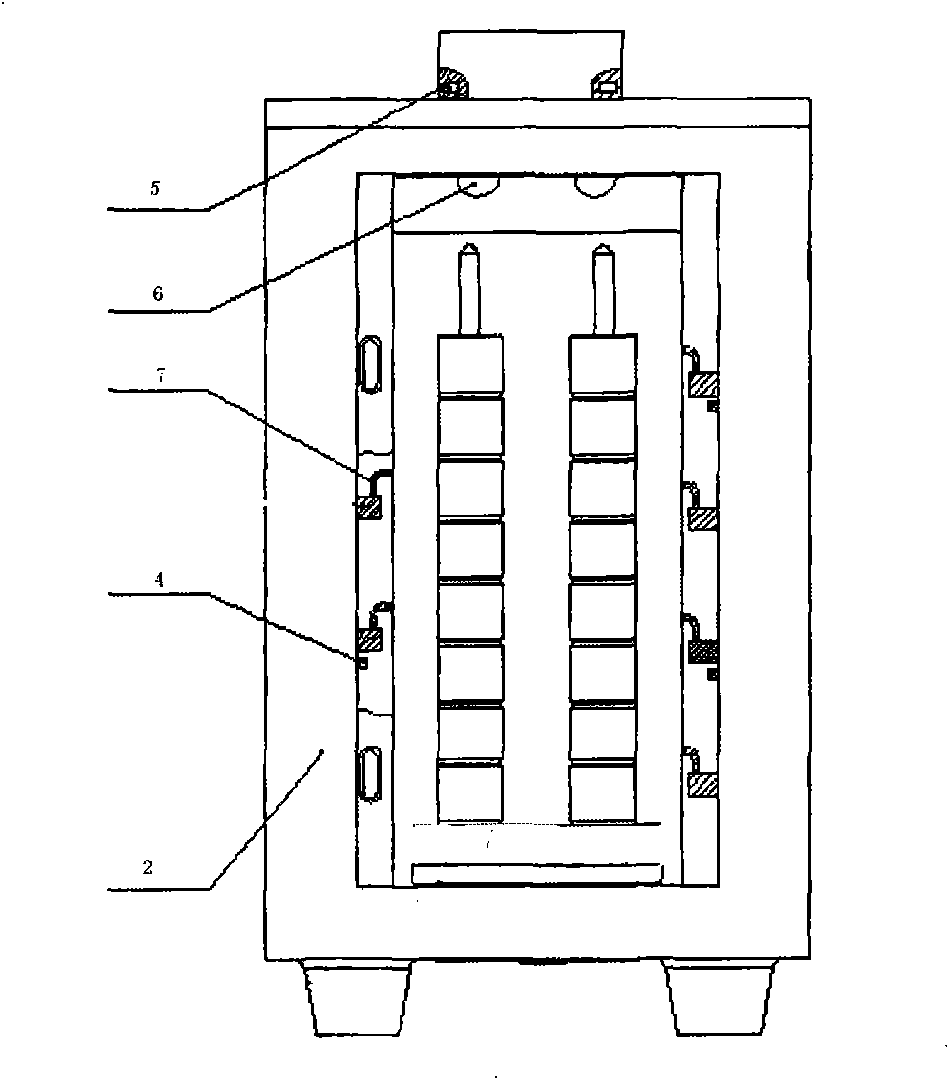

[0030] An embodiment of the present invention provides a continuous microwave curing equipment for vacuum pressure impregnation electrical equipment, including a conveying track, a base that can run along the track, a microwave curing device, an online detection device and a PLC control device; wherein the The microwave curing device is equipped with a microwave triode or a tetrode; and each of the microwave curing devices can accommodate a plurality of bases that can run along the track to move therein, and the base is housed on the base for vacuum pressure dipping treatment. equipment; the microwave curing device is connected with vacuum equipment.

[0031] Among them, the base that can run along the track is located inside the microwave curing device. Specifically, it is set above the bottom of the microwave curing device for microwave curing treatment; the online detection device is installed inside the microwave curing device to detect the spray paint inside the microwave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com