Numerical control bearing ring turning automatic line

A technology of bearing rings and automatic lines, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve problems such as inaccurate clamping positioning, low production efficiency, and damage to props, so as to avoid misoperation and human error , reduce the impact of workpieces, and reduce the effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

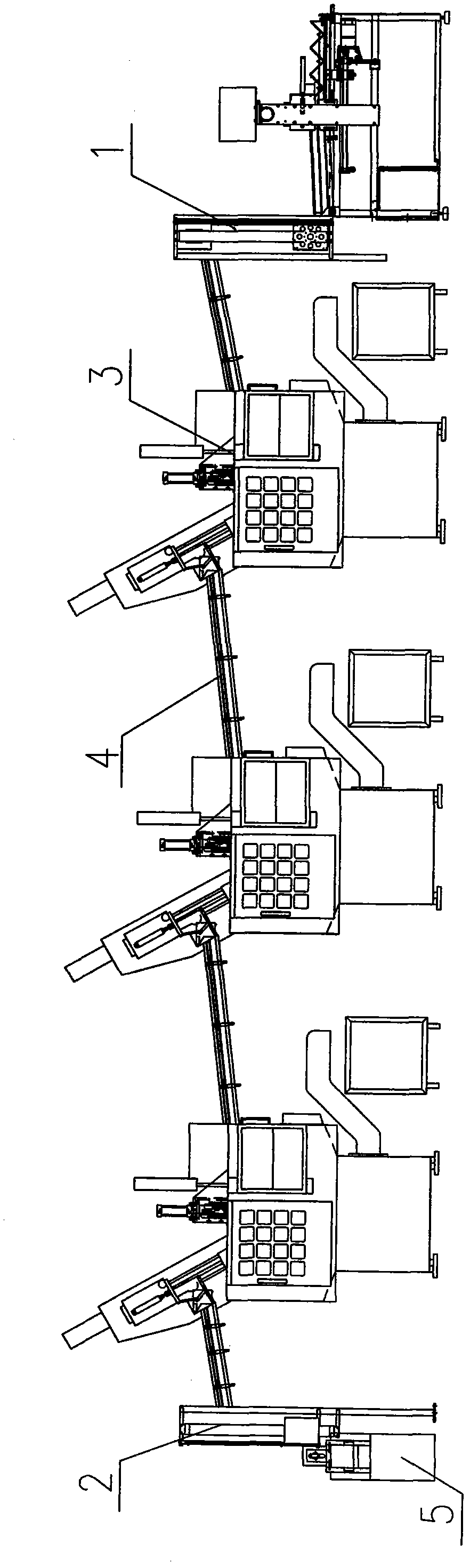

[0014] Specific implementation mode one: as figure 1 As shown, a CNC bearing ring turning automatic line, the automatic line includes a feeder 1, a blanking machine 2, an automatic control line system and three CNC lathes 3, the automatic control line system respectively controls the feeder 1, The blanking machine 2 and the numerically controlled lathe 3 work automatically; a connecting feedway 4 is respectively arranged between each two adjacent numerically controlled lathes 3, and an automatic detection device is arranged in the connecting feedway 4, and the automatic detection device uses It is used to detect whether the processed bearing ring meets the standard. The automatic control line system includes the automatic control system with PLC as the controller and the material sorting and cleaning machine. The sensor on the cleaning machine 5 controls the feeding of the feeder, the blanking of the unloading machine, and the cleaning and antirust and material work of the cl...

specific Embodiment approach 2

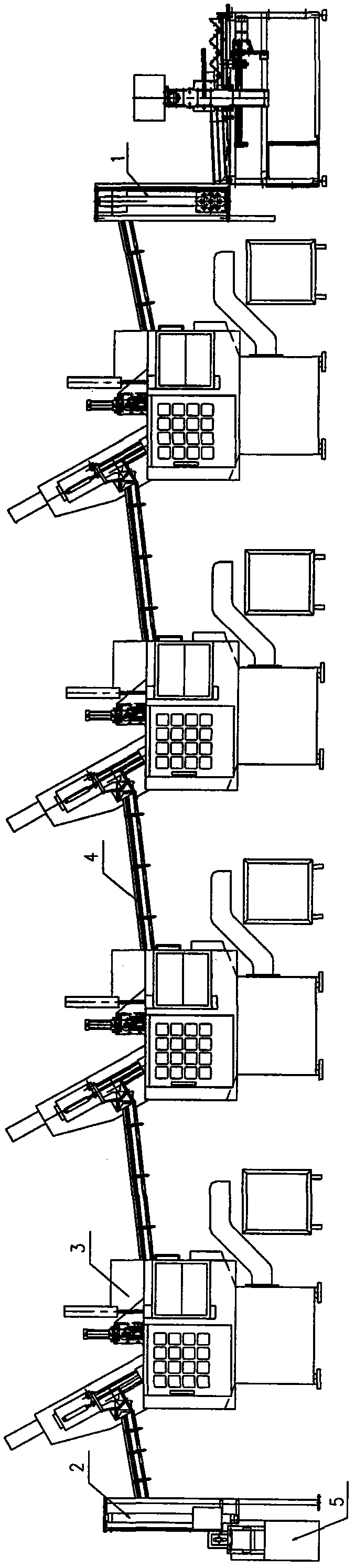

[0022] Specific implementation mode two: as figure 2 As shown, a CNC bearing ring turning automatic line, the automatic line includes a feeder 1, a blanking machine 2, an automatic control line system and four CNC lathes 3, the automatic control line system controls the feeder 1, The blanking machine 2 and the numerically controlled lathe 3 work automatically; a connecting feedway 4 is respectively arranged between each two adjacent numerically controlled lathes 3, and an automatic detection device is arranged in the connecting feedway 4, and the automatic detection device uses It is used to detect whether the processed bearing ring meets the standard. The automatic control line system includes the automatic control system with PLC as the controller and the material sorting and cleaning machine. The sensor on the cleaning machine 5 controls the feeding of the feeder, the blanking of the unloading machine, and the cleaning and antirust and material work of the cleaning machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com