Automatic welding and blocking device with circumferential and universal angle

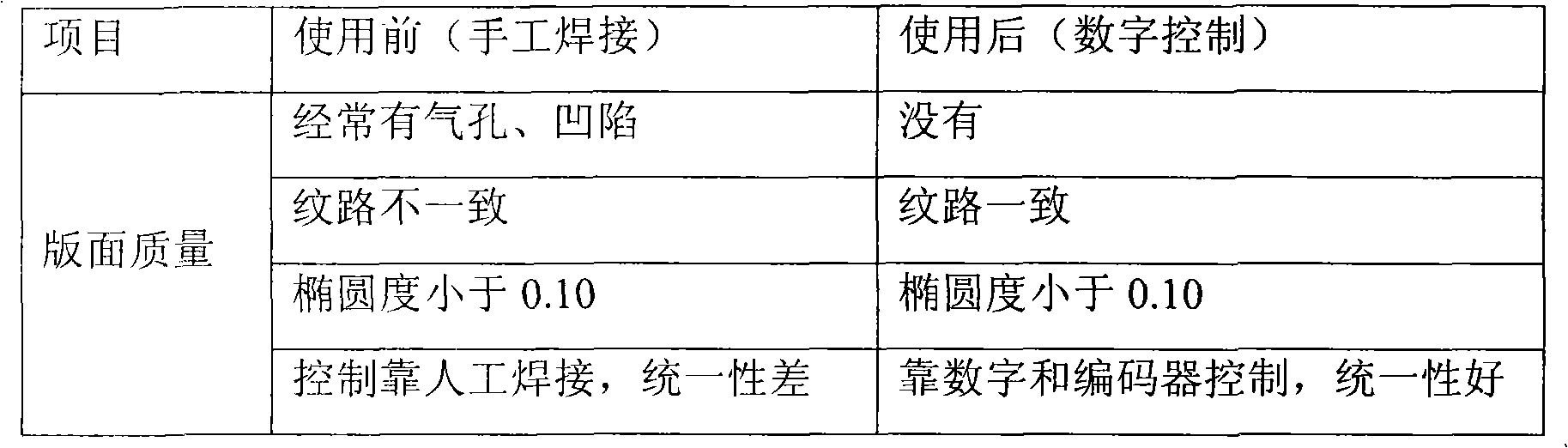

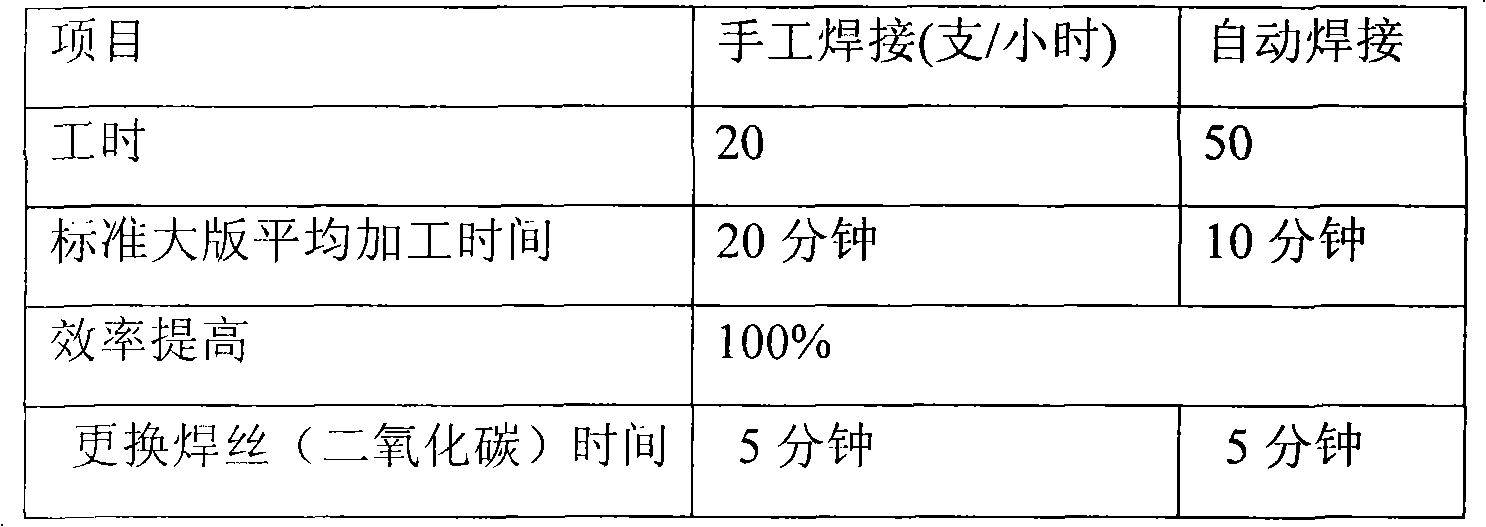

A universal angle, automatic welding technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of defective welding surface quality, unstable surface quality, uneven welding, etc., to reduce copper plating quality problems, The effect of convenient and rapid replacement and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

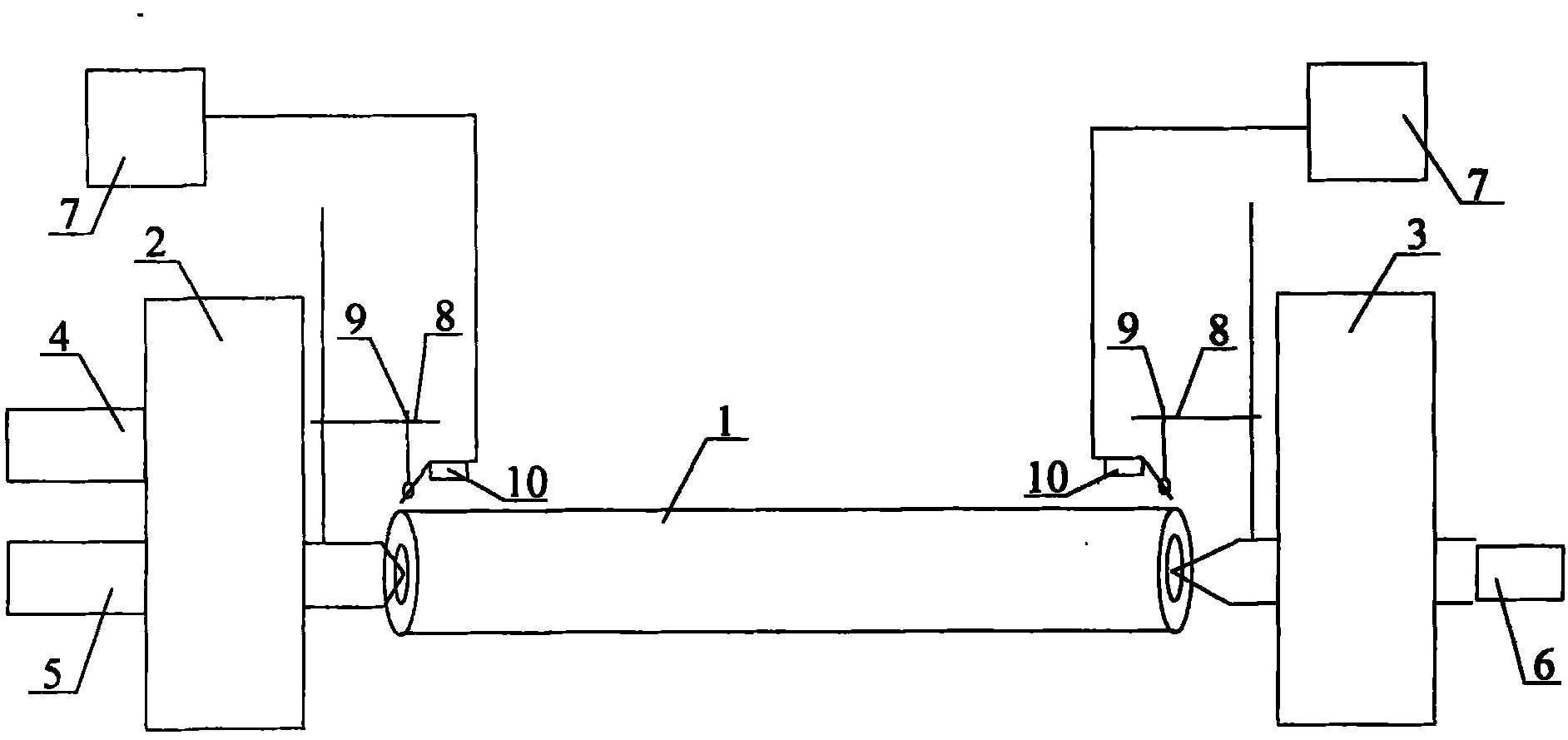

[0024] A circumferential universal angle automatic welding plugging device, its structure is as follows figure 1 As shown, the device is composed of a plate roller rotating assembly, a control assembly, a welding machine 7, a bracket and a welding torch 10. The plate roller rotating assembly is a rotatable cylindrical plate roller 1, and the two ends are respectively provided with a bedside support 2 and a bedside support. Part 3, the control assembly includes a digital controller 4, a motor 5 and an encoding controller 6, the digital controller 4 and the motor 5 are arranged on the outside of the bedside support 2, the encoding controller 6 is arranged on the outside of the bed end support, and the welding machine 7 is a welding machine protected by carbon dioxide gas, which is arranged at both ends of the rotating assembly of the plate roller, and the support is arranged on one side of the rotating assembly of the plate roller, including the left and right movable supports 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com