Portable grinding device for woodworking planer

A woodworking planer and portable technology, applied in the field of portable woodworking planer sharpeners, can solve the problems of high time-consuming, high cost, immobility and the like, and achieve the effects of being easy to carry, low in cost and good in sharpening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

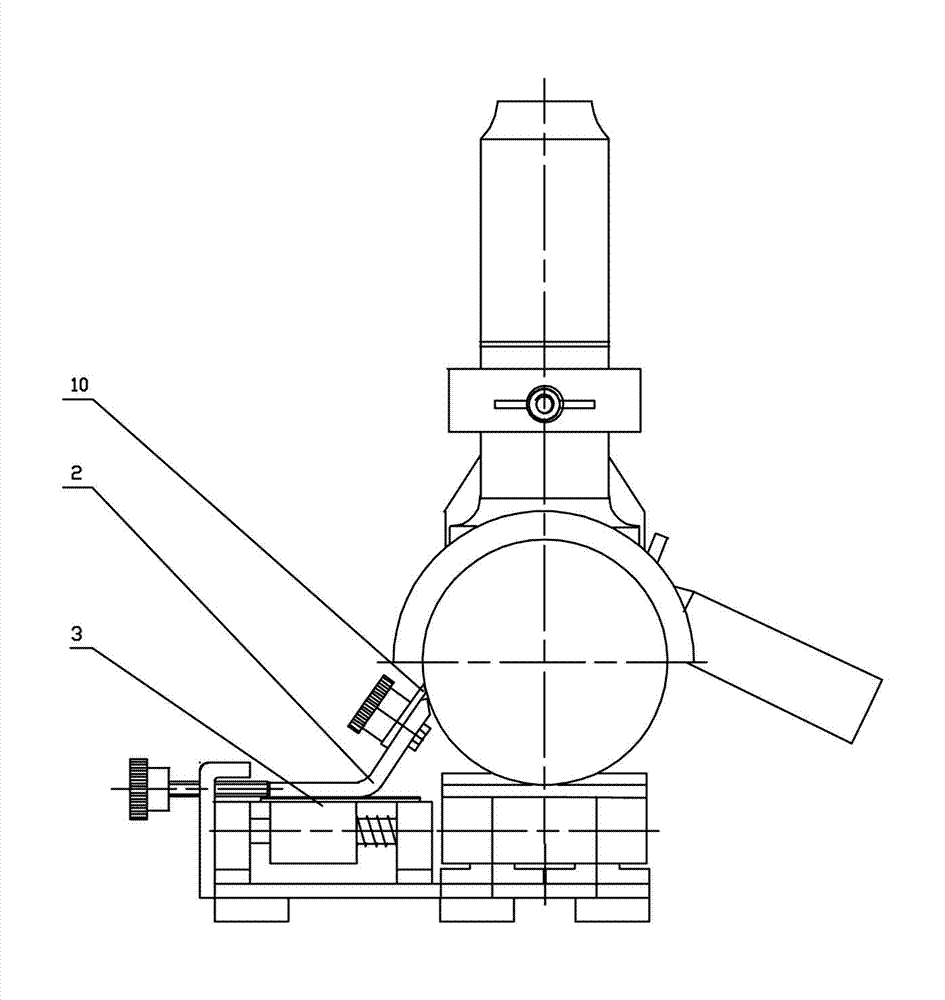

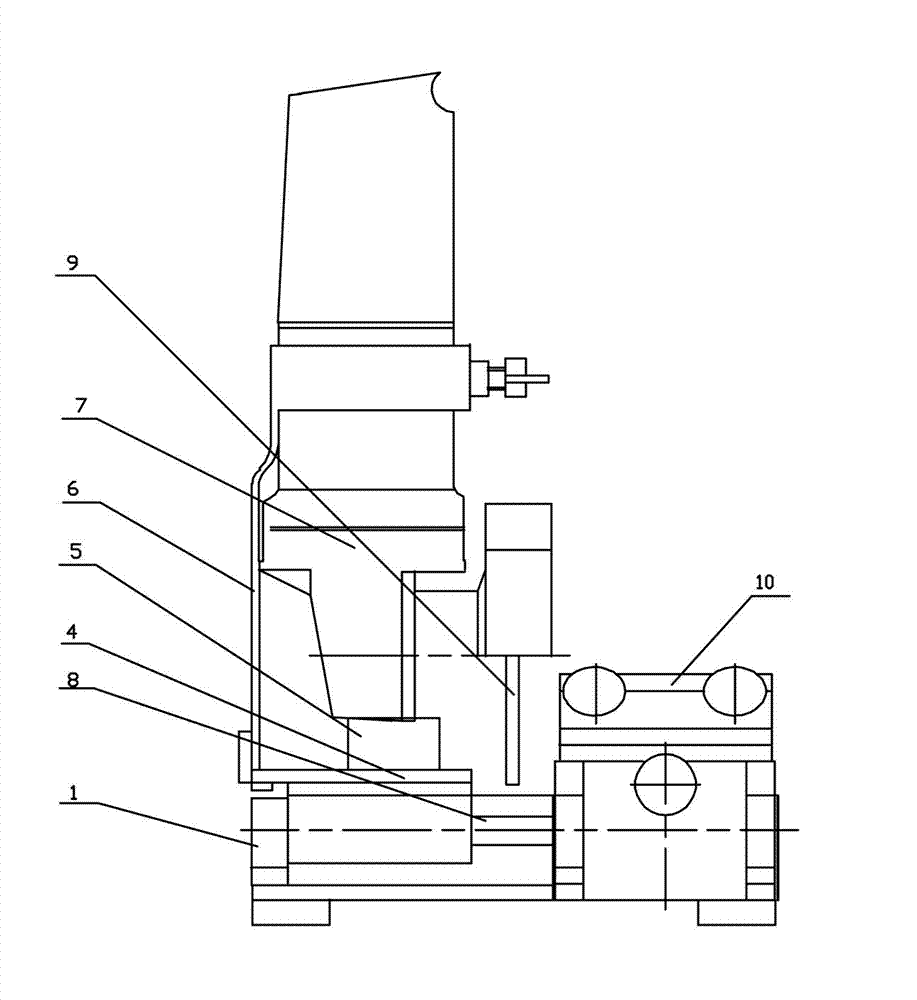

[0022] Such as figure 1 , figure 2 As shown, the present invention provides a portable woodworking planer sharpener, which includes a stamped machine base 1, a tool positioning and clamping mechanism 2 with a knife setting block, a feed slide 3 slidingly matched with the machine base 1, and a The suitcase of machine base 1, and the grinding slide 4 slidingly matched with machine base 1, wherein the positioning and clamping mechanism 2 is fixed on the feed slide 3, and the feed slide 3 is fed by a screw rod, and the grinding slide 4 Slide along the guide rail 8 fixed on the machine base 1, the direction of the guide rail 8 is perpendicular to the sliding direction of the feed slide 3, and the positioning seat 5 and the fixing frame 6 are arranged on the grinding slide 4, and the positioning seat 5 is adjusted by the adjusting bolt Conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com